Com o rápido desenvolvimento das máquinas de dobragem no país e no estrangeiro nos últimos anos, surgiram no mercado vários sistemas CNC para máquinas de dobragem, tais como a série holandesa DELEM, a série suíça CYBELEC e a série italiana ESA, que são as mais exportadas.So how do you choose from the wide variety of systems? This probably makes many customers feel overwhelmed. In fact, it will be much easier if you follow the following points.

System operation should be simple

We choose CNC bending machines for the purpose of using the machines more conveniently and creating more value for production. If the system design is complex and the operation is cumbersome, then no matter how good the system is, it may not be suitable for us. Imagine if our employees have problems operating the system, can we still achieve the efficiency and precision that the system should have? Therefore, an excellent CNC system must be easy to operate, easy to learn and easy to use.

The system must be stable

The importance of system stability is obvious. No one wants the machine to have problems just a few days after purchase, which will affect the mood and delay production. So how do we know whether the system is stable?

1.Brand and series selection

First of all, we need to look at the years, reputation and number of the bending machine brand in the market to infer whether the brand is mature or not. If a brand has not been tested and investigated by the market, then the brand is definitely not mature, and there will inevitably be small problems of one kind or another. This phenomenon is like a copycat mobile phone and an Apple mobile phone. Although the appearance is the same, the functions and uses are far apart.Common operating systems for CNC bending machines are mainly divided into the following categories:

DELEM series system

DELEM of the Netherlands is a global leader in CNC bending machine control systems. Its product line includes DA-41, DA-52, DA-66T, DA-69T and other series. The DELEM system is famous for its graphical interface, user-friendly operation experience and powerful functions, and is suitable for complex multi-axis bending operations.

The integrated DA-52S CNC system can be applied not only to the control of the torsion axis synchronous bending machine, but also to the control of the electro-hydraulic synchronous bending machine. The panel-type installation structure based on the 4-axis control can be installed directly on the electric cabinet or in the suspended cabinet. The DA-52S system with a friendly user interface and TFT true color LCD display has all the basic functions of the bending machine control. Its unique "shortcut key" method provides fast and concise programming. The Y-axis angle programming, the table deflection compensation function and the pressure control are all standard configurations. The DA-52S system provides a stable and reliable solution. Its equipped USB interface greatly facilitates the rapid backup of products and molds.DA-52S is an important transition for DELEM from the CNC system of torsion axis bending machine to the CNC system of electro-hydraulic bending machine. The DA-50Touch series bending machine system provides a multi-functional solution for the powerful electro-hydraulic bending machine. Of course, compared with the later DA-53T and even DA-69T, the functions of DA-52S may not be powerful enough, but considering the price, DA-52S is very suitable for users with low needs.

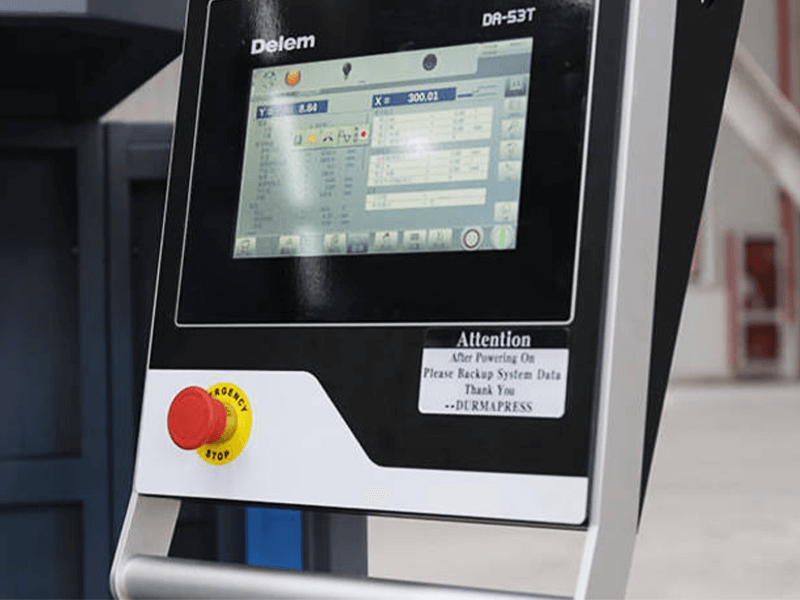

DA-53T provides a perfect full touch control solution for electro-hydraulic bending machines. The panel type is the basic installation method, which can control up to 4 axes, and the suspension installation method can be selected. It is equipped with a 10.1" high-resolution TFT color wide-body display and an integrated industrial-grade multi-touch screen, which can easily access the Delem user interface. You can use shortcut keys to quickly switch between the programming and processing interfaces. The overall design is optimized based on ergonomic principles to make the operation more convenient and user-friendly. Through the quick and convenient "programming directly to production" process, the time for machine tool adjustment and trial bending is greatly reduced. The USB interface facilitates the rapid backup/restore of molds and products. The standard configuration is 3+1 (Y1, Y2, X-axis and deflection compensation) and the other optional axis can be used for the R-axis or Z-axis.Compared with the DA-52S system, the DA-53T retains the advantages of compensation system control, USB backup and recovery, 24 optional languages, etc., but increases the screen to 10.1", makes the screen touchable, and supports offline software use, which makes it more convenient and smooth for users to use, but the price has also increased accordingly.

DA-58T, with its high-definition color TFT display and industrial-grade multi-touch technology, allows easy access to ELEM's user application interface. It provides more direct and quick navigation function keys for product programming and machine tool settings, shortening operation time. By quickly and conveniently programming to the production process, the time for machine tool adjustment and test bending is minimized. Independent CNC programming interface, automatic position calculation of all axes, true-to-scale machine tools and molds simulate the bending process. The 2D programming provided by DA-58T includes automatic calculation and collision detection of the bending process. The production mode of DA-58T provides a simulation of the product's bending process to help operators operate during processing. Standard machine tool functions Y1-Y2 and X-axis, the second stop axis can be used for the R-axis or Z-axis, and the compensation axis is also standard.

Compared with DA-53T, DA-58T has a larger screen size of 15", and has added new functions such as drawing and 2D graphics programming. It also adds a network interface that can be directly connected to the Internet and an option that is universal to computers, making the bending workpiece more intelligent.

DA-66T provides 2D product programming, automatic calculation of bending process and collision detection functions. 3D all-round, multi-station molds show the feasibility of bending operation of real machine tools in real time. More efficient algorithms are used to optimize the entire machine tool work, shorten the operation cycle, improve the machine tool work efficiency, and make it more convenient to adjust and control the machine tool.Compared with previous models, DA-66T has taken CNC systems to a new level. The 17" large screen, 3D graphics simulation display, complete Windows application package, compatible with DELEM modular structure, angle detection sensor interface and other functions make DA-66T a highly cost-effective system, which is very popular among users.

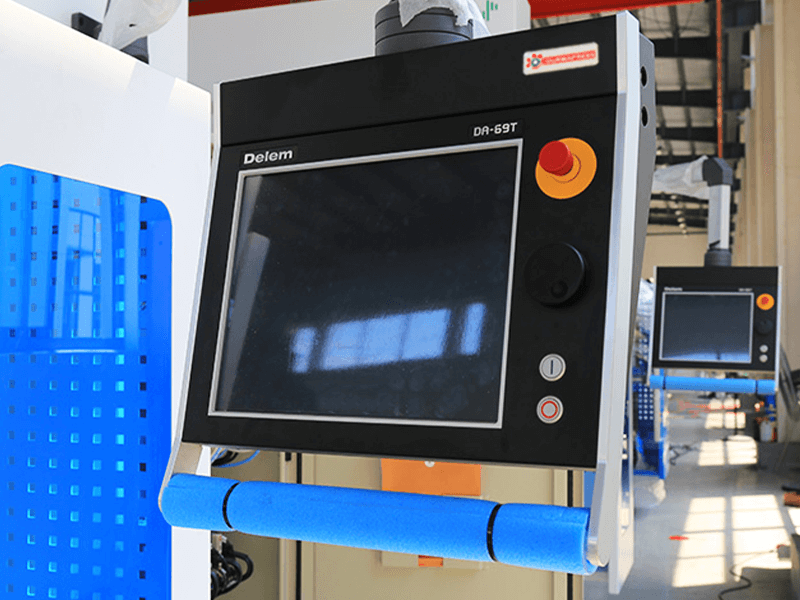

DA-69T adds 3D touch programming based on DA-66T. It is not very cost-effective, but it is more convenient to use.

Cybelec system

Swiss Cybelec is also a well-known manufacturer in the field of CNC bending machine control. Its main products include DNC 60, DNC 880S, ModEva series, etc. Cybelec system is popular for its good stability, flexible programming and intuitive operation interface, and is widely used in high-precision sheet metal processing.

Bosch rexroth system

This is a German company whose bending machine control system integrates a rich range of automation solutions for application scenarios that require high-precision and efficient processing.

SDA system

The SDA system is a control system commonly used in bending machines produced in China. It is simple to operate and low in cost, and is suitable for some occasions with low control accuracy requirements.

ESA system

ESA mainly provides high-end controllers for CNC machine tools. Its bending machine operating system supports touch screen operation, has high customizability and powerful bending programming functions, and is suitable for production tasks of different scales.

ESTUN system

ESTUN is a well-known CNC system manufacturer in China. Its bending machine control system has high cost performance and wide application. The ESTUN system supports multi-axis control, simple programming, convenient operation, and is suitable for daily sheet metal processing of small and medium-sized enterprises. Common models include E21, E200P, E300, etc., with stable performance and can meet most bending needs.

The operating systems of CNC bending machines of different brands and models differ in interface design, programming methods and functions. When choosing, you need to consider the specific processing requirements, budget and the operator's familiarity.

2.Experienced manufacturer

In addition to the brand of the bending machine, it also depends on the system manufacturer. The system produced by a senior automation manufacturer will be more stable. In fact, the essence of CNC machine tools is mechanical automation, and even college students of related majors can develop it, but few can really achieve successful applications. What is the reason? In fact, the ideal environment is far from the actual environment. At the same time, there is a lack of a core technical team, so it is impossible to develop a satisfactory system. Systems developed by large companies, such as the DELEM series in the Netherlands, the CYBELEC series in Switzerland, the ESA series in Italy, the MD series in Hong Kong, China, and the SNC series in Nanjing, Jiangsu, etc., are all high-quality systems that are often chosen by everyone. After determining the brand series, the specific model to be selected should be based on the purpose, working environment, the degree of bending required, the thickness of the thin plate, the effect of the bending workpiece and other conditions, and then combined with the budget for purchase.

Is the after-sales service timely?

Check whether the manufacturer's after-sales service is timely. After determining the budget, find the largest, longest-established, and best-funded manufacturer within the budget. Do not rush to buy at a low price, because low prices are either cutting corners or replacing the original with new ones, or using a bunch of junk in terms of configuration. The key is to ensure cost-effectiveness, quality, and after-sales service.

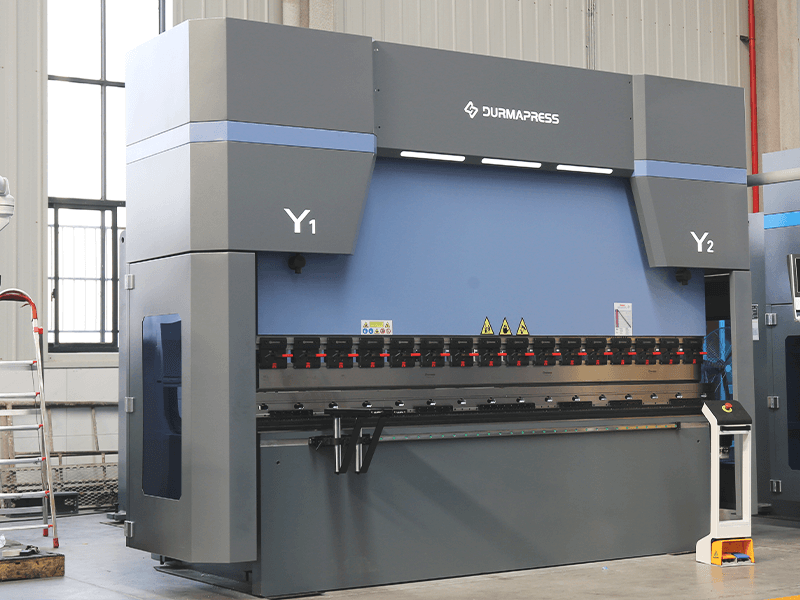

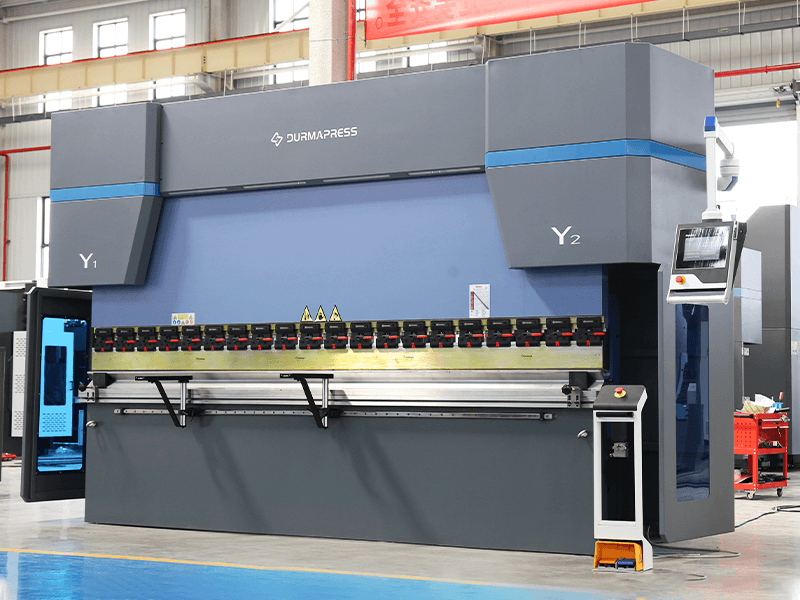

Durmapress factory recommendation

Here I recommend the bending machines produced by Durmapress factory. Durmapress is a modern enterprise that produces various common and CNC bending machines, shearing machines, laser cutting machines, punching and shearing machines and other machines. It has a complete production supporting process, an independent factory, and provides professional and personalized product customization. Durmapress always adheres to the business principle of "manufacturing high-quality machines and providing first-class after-sales service". Therefore, the performance and details of Durmapress machines can be guaranteed to exceed 95% of peers in the market and continue to improve. Independent research and development of drawings makes the appearance of the product more high-end and fashionable, and has its own appearance patent. Durmapress also adheres to the basic ethics of honest operation and treats every customer seriously, so there are often many old customers who often repurchase. We believe that only by ensuring excellent product quality and good after-sales service can customers faithfully trust us.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)