Explicação dos problemas comuns de prensa dobradeira encontrados pelos clientes e processo de aceitação

The process of troubleshooting the cylinder drop problem of the press brake

1.Troubleshooting process

- Cleaning back pressure valve

- Cleaning and blowing down valve

- Remove rust from inside the oil cylinder or replace the sealing ring

2.Solution to the cylinder drop problem

If the first two steps of cleaning are ineffective, try swapping the quick-release valve and the back pressure valve on both sides of Y1Y2. If the problem occurs on the other side, it means that one of the quick-release valve and the back pressure valve has a problem. Consider replacing or cleaning the back pressure valve several times. During the cleaning process, be sure to pay attention to surface cleaning. The valve hole after disassembly also needs to be cleaned.

If the cylinder still falls off after the valve group is replaced, you need to check the sealing ring and rust inside the oil cylinder.

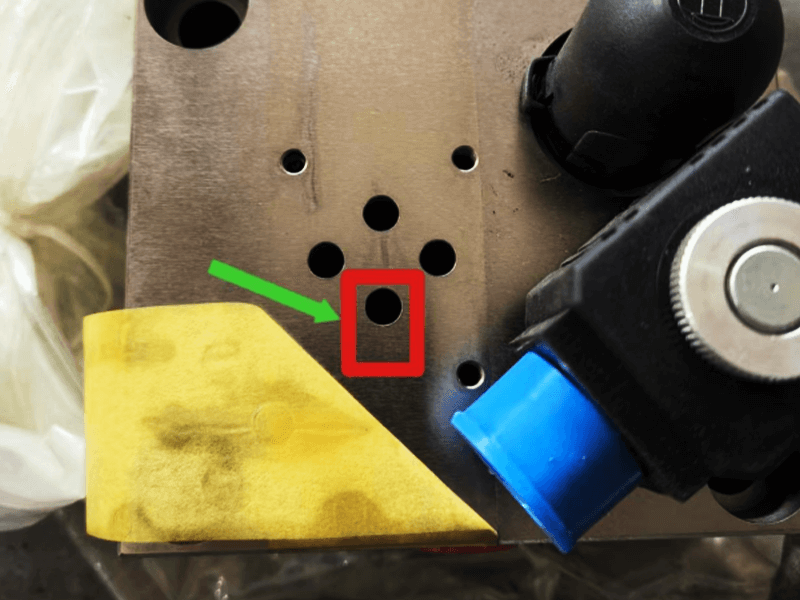

Steps: First, lift the machine, then remove the proportional valve assembly. There are four holes on the valve group base. Pay attention to whether the bottom hole has oil gushing out or is always in the state of oil gushing out. If there is still no oil gushing out after waiting for two minutes, it means that there is an internal leak in the oil cylinder. Then remove the oil cylinder for inspection. During the installation and disassembly process, the valve group sealing ring must be installed well!

Note: The cylinder drop of the machine is only related to the internal sealing ring or cleanliness of the cylinder of the quick-down valve back pressure valve. It has nothing to do with the proportional valve.

There is no up and down movement when searching for the reference point

When the machine is looking for a reference point and does not move up or down, you can enter the system's diagnostic page, change the left valve offset and the right valve offset to 20%, and then press button No. 2 under the digital signal output to see if the machine can descend. If it does not work, consider cleaning the proportional valve.

Note: Pay attention to the integrated coil circuit on the proportional valve. Remember not to mess up the four blue wires. You need to remove the small plugs on the four blue wires. Do not break the four blue wires during the removal process.

Some troubleshooting of machine startup issues

1.Check whether the thermal protector is tripped

If the oil pump cannot be started, consider checking whether the thermal protector has tripped. There is a small red button and a small gray button on the thermal protector. Press the red reset button first, then press the gray reset button.

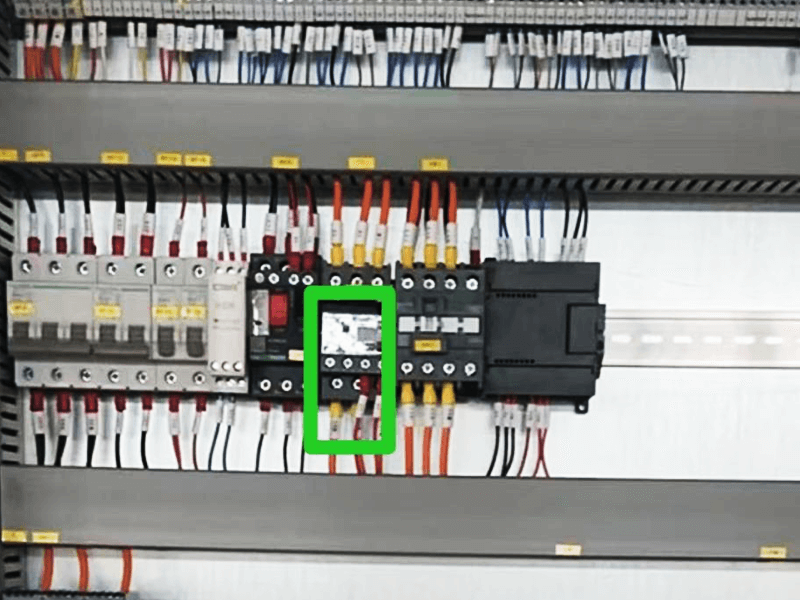

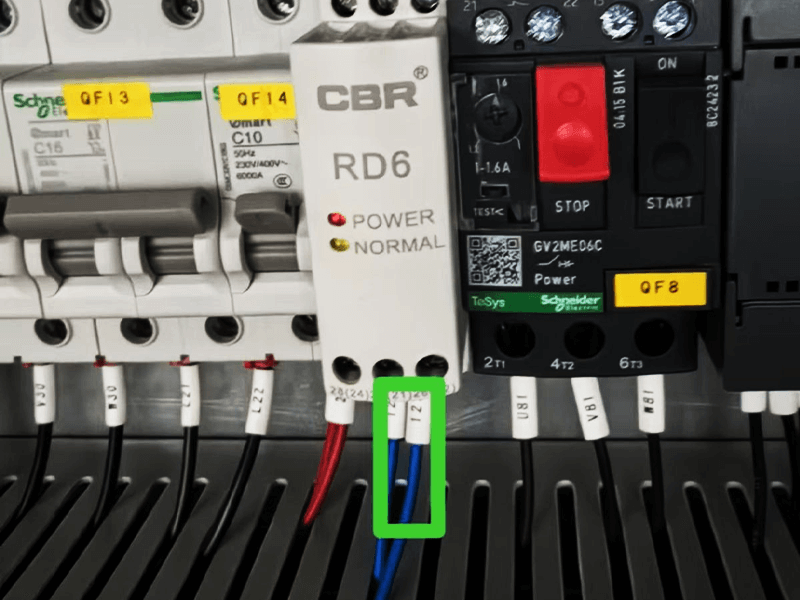

2.Check whether the phase sequence protector indicator lights are all on

Check if both indicator lights of the phase sequence protector are on. If it fails to start under normal use and only one light is on, consider that the phase sequence protector is overheated and damaged. It needs to be replaced. If the customer needs to use it urgently, you can remove the two wires at the bottom and connect them together, wrap them with insulating tape, and be sure to turn off the power! ! ! Some models or wire numbers are different, but you only need to connect the two wires in the position shown in the figure below.

Inspection process after receiving the machine

1.Check the integrity of the machine

Check the exterior and core parts of the machine body for any damage. If there is any damage, please contact us immediately. This includes: Check whether the main motor, electric cabinet, servo motor of the back gauge and the plug of the machine circuit part are damp and water ingress, and check whether the pipe joints of the oil circuit are loose due to transportation. Check whether the cortex of the high-pressure hose is squeezed or damaged. When installing the valve group, keep the surrounding environment clean, and check whether the sealing ring is installed in place.

2.Check the oil pipe joint and install the sealing ring

When installing the oil pipe, be sure to check the oil pipe joint and install the sealing ring, then connect the oil pipe, and make sure the joint is tight! Any looseness will also cause the oil pipe to rupture because the oil pipe will be unevenly stressed.

3.Check the cleanliness of the inside of the fuel tank

Check the cleanliness of the inside of the oil tank. Due to transportation at sea or on the road, there may be rust inside. You need to open the oil tank for inspection and clean it before filling it with hydraulic oil. The oil level should be above 80 on the level gauge.

4.Check the tightness of the plug and conduct wiring test

Check the tightness of the plug in the electrical cabinet and conduct wiring test without error under dry conditions.

5.Test the back pressure valve pressure

After the machine is started, put the machine in the slow-down state, connect the valve group on the cylinder to test the back pressure valve pressure. When the machine is in the slow-down action, check whether the back pressure is 8 MPa.

6.Carry out lubrication maintenance

The parts of the machine body that need lubrication should be lubricated and maintained with hydraulic oil or lubricating oil.

7.Check whether the machine is running forward

After connecting the power cord and supplying power, check whether the two lights of the phase sequence protector inside the electrical cabinet are always on, which means that the machine is rotating forward.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)