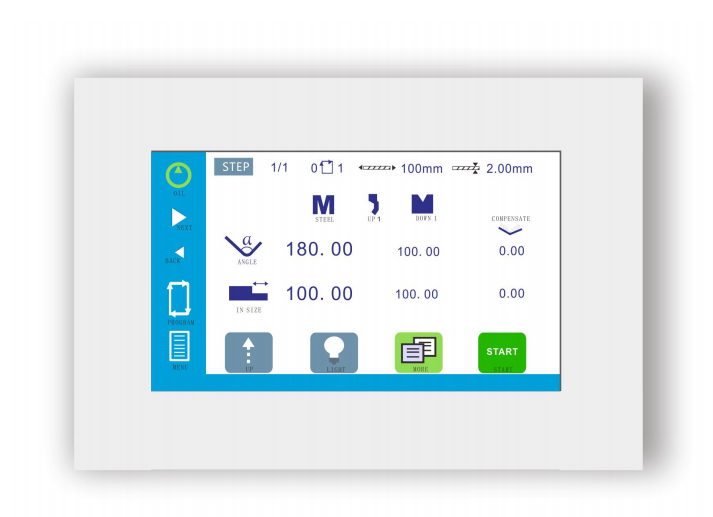

CNC Press Brake TP10S CNC Touch Screen Controller - User Guide

1 Overview.....................................................................................................................................3 1.1 Programming/running............................................................................................................3 1.2 More programming................................................................................................................3 1.3 Advanced parameters............................................................................................................. 4 1.4 Mode selection.......................................................................................................................5 1.5 System parameter...................................................................................................................6 1.6 Machine diagnosis................................................................................................................. 6 2.Debugging system................................................................................................................7 2.1 Valve settings.......................................................................................................................... 7 2.2 Coefficient.............................................................................................................................. 8 2.2.1 X axis....................................................................................................................................8 2.2.2 Y axis................................................................................................................................... 8 2.3 Angle Debugging.................................................................................................................... 9 2.3.1 Upper mold..........................................................................................................................9 2.3.2 Lower mold..........................................................................................................................9 2.3.3 Other parameter.................................................................................................................10 2.4 Angle calibration.................................................................................................................. 10 2.5 Length of calibration.............................................................................................................11 2.6 Frame strength......................................................................................................................12 2.7 Grid ruler.............................................................................................................................. 12 2.8 Mechanical compensation................................................................................................... 13 2.9 Great arc............................................................................................................................... 13 2.10 Y1-Y2 axis.............................................................................................................................14 3.User operation.....................................................................................................................14 3.1 Single… Ler mais "CNC Press Brake TP10S CNC Touch Screen Controller - User Guide