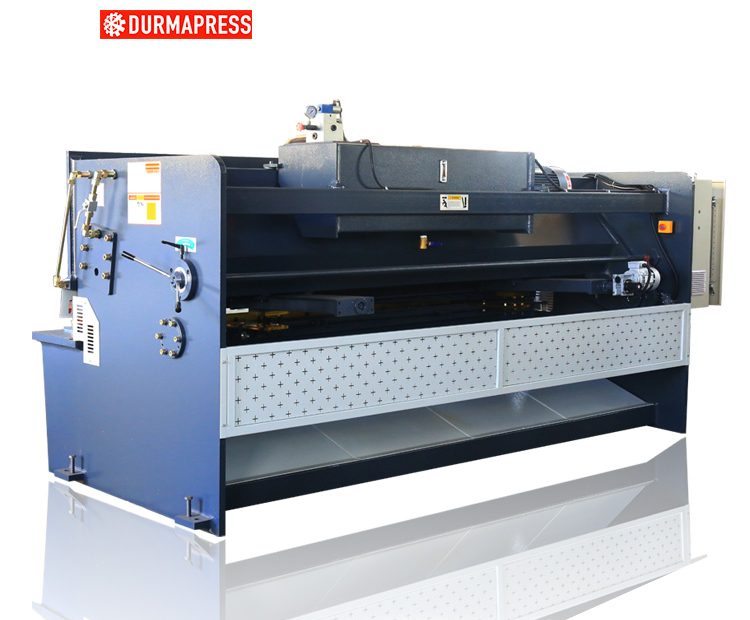

What are the main points of concern in operating a hydraulic plate shears?

The working effect of the hydraulic plate shears is closely related to its debugging and correct operation. Today we will introduce the debugging and correct operation steps of the hydraulic plate shears. Now, we first introduce the correct operation of the hydraulic plate shears to you: 1, start the machine for several idling cycles, ensure that under normal conditions, test shear different thickness of sheet, from thin to thick. Ensure users are familiar with machine performance. 2.The gap between different blades… Ler mais "What are the main points of concern in operating a hydraulic plate shears?