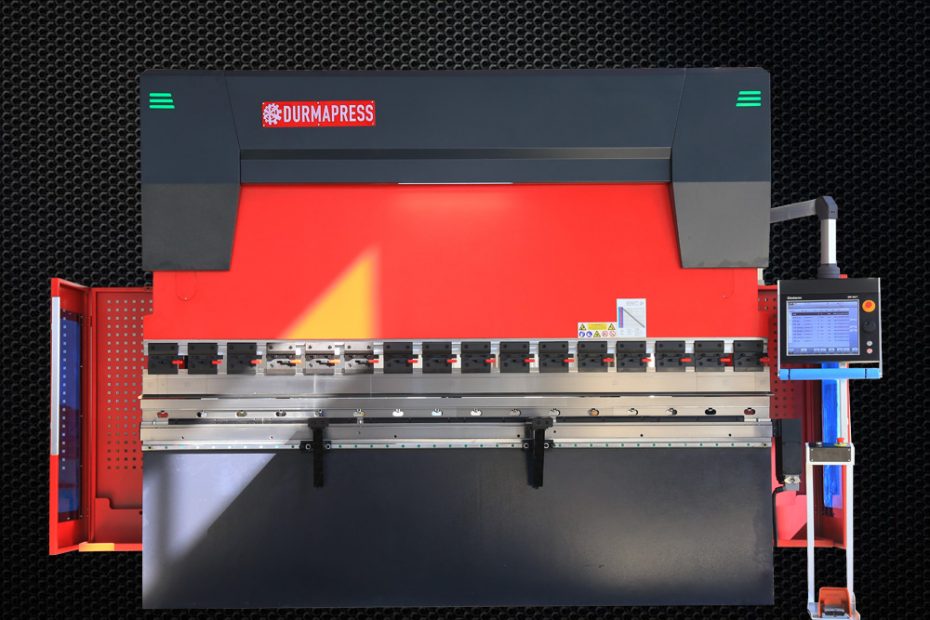

Preço da máquina de dobragem CNC: como prolongar a vida útil da máquina de dobragem

O preço da máquina de dobragem CNC para obter uma vida longa, no processo de dobragem deve ser o mais longo possível para aderir ao corte contínuo. Se a matriz da máquina de dobragem entrar e sair com demasiada frequência, a vida útil da matriz da máquina de dobragem será significativamente reduzida. Isto irá aumentar o stress térmico e a fadiga térmica na aresta de corte. Uma temperatura uniforme e alta na área de corte é mais favorável para as modernas matrizes de máquinas de dobragem de metal duro do que um grande abalo. O... Ler mais "Preço da máquina de dobragem CNC: como prolongar a vida útil da máquina de dobragem