Introduction

The importance of choosing the correct Press Brake model cannot be overstated for industrial production. Different types of Press Brakes and their operating systems can meet various production needs, ensuring optimized product quality and efficiency. This article will outline several common Press Brake models and their related operating systems to help readers better understand how to choose the appropriate equipment.

Overview of Different Press Brake Models and Their Operating Systems

Selecting the right Press Brake model not only enhances production efficiency but also ensures bending accuracy and product quality. Different models of Press Brakes vary in performance, control systems, and application scope. Understanding these differences can assist businesses in making wiser decisions, avoiding unnecessary costs, and production stagnation.

Common Press Brake models include WC67Y, WC67K, WD67Y, WE67K series, among others. To better understand the meanings of these models, let's take WC67Y-63T/2500 as an example for detailed explanation.

Analysis of Bender Model Naming Instances

Commonly seen bending machine models in China include the WC67Y, WC67K, WD67Y, and WE67K series. To better understand the meanings of these models, let's break down and analyze the WC67Y-63T/2500 model as an example.

Model Breakdown and Meanings

Commonly seen bending machine models in China include the WC67Y, WC67K, WD67Y, and WE67K series. To better understand the meanings of these models, let's break down and analyze the WC67Y-63T/2500 model as an example.

W - Bender Code

The "W" stands for "bender" as it belongs to the category of bending and straightening machines in metalworking machinery.

In metalworking machinery, different types of machines are represented by capital letters of their Chinese pinyin, for instance, the "Q" stands for shearing machine.

C - Product Structure Type

The second letter "C" represents significant structural changes and differences in the main structure of the product.

Based on different structural designs, benders can be classified into the following categories:

A: Worktable moves upward

B: Parallel cylinder hydraulic synchronization

C: Torsion-bar synchronized bender (widely used, good synchronization, high accuracy)

D: Mechanical-hydraulic synchronized bender

E: Electro-hydraulic synchronization

67 - Series Number

The number "67" indicates the series number of the bender within the bending and straightening machine group.

Different series numbers represent different types of machines.

Y - Transmission Method

The letter "Y" stands for hydraulic transmission.

"K" represents numerical control.

63T/2500 - Pressure and Worktable Length

"63T": The pressure capacity is 63 tons.

"2500": The worktable length is 2500 millimeters.

Case Study: WC67Y-63T/2500

W: Indicates that this is a bender.

C: Uses a torsion-bar synchronized structure, which is widely applied and has good synchronization and accuracy.

67: Belongs to the general bender series.

Y: Uses a hydraulic transmission method, suitable for general bending operations.

63T: The bending machine has a pressure capacity of 63 tons, suitable for processing metal sheets of moderate thickness.

2500: The worktable length is 2500 millimeters, suitable for sheets of moderate length.

Hydraulic Press Brake Examples WC67K Press Brake with ESTUN E21 Control System

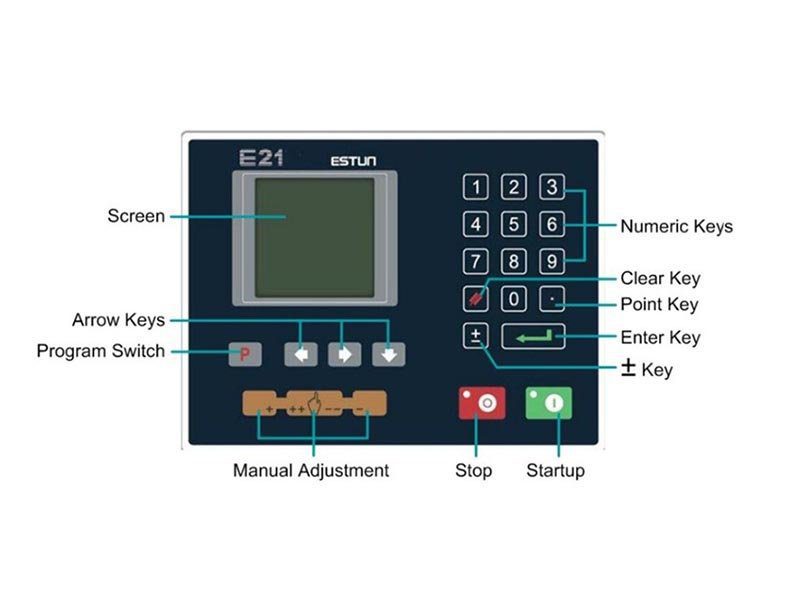

The Estun E21 press brake controller enhances press brakes and shears with precise, smart cuts and bends. It's easy to operate with high-cost performance, featuring micro switch buttons and has undergone rigorous EMC, high temperature, and vibration testing for stability and durability. Key features include CNC back gauge control, motor or inverter control, intelligent positioning, pressure unloading time setting, workpiece counting, 40 program storage with 25 steps per program, unilateral positioning, concession function, one-key backup/restore, and support for mm/inch and Chinese/English languages.

WE67K Press Brake with delem DA-69T Control System

The DA-69T DA-Touch 3D modular press brake control offers advanced solutions for efficient press brake programming and operation. Featuring a 17" high-resolution touch screen, it supports both 2D and 3D programming with automatic bend sequence calculation and collision detection. The user-friendly interface enables easy navigation and improved ergonomics, while the real-time Linux OS ensures reliability. Key features include 3D machine setup, modular scalability with Delem Modusys compatibility, sensor bending and correction interface, and full Windows application suite. The system also supports USB interfacing and offers profile-T3D offline software for enhanced productivity and accuracy.

WD67Y Press Brake with Delem Series Control System

Delem is a well-known manufacturer of Press Brake controllers, specializing in producing Press Brakes for metal processing. Press Brakes are used for bending and shaping metal sheets, while Delem controllers are electronic systems for managing and automating Press Brake operations. It is used for programming and controlling the bending process of Press Brakes, including setting bending angles, positions, and depths. Operators can input specifications for bending operations, and the Press Brake will then execute the operation automatically. Delem controllers feature a user-friendly interface and provide advanced functions such as automatic calculation of bending parameters, automatic angle correction, and programming complex bending sequences. Additionally, it is equipped with safety features to prevent accidents, protecting operators and machines.

Electric Press Brakes EP03-01, EP03-02, EP03-03 Electric Press Brakes with Ordinary CNC Systems

This series of Press Brakes are generally equipped with around 2kW motor power. The core selling point is its high precision, suitable for industries such as building materials stores, repair shops, and production workshops. It features high automation, energy-saving, and a core component warranty period of 2 years. Core components include bearings, motors, PLCs, and ball screws. The exterior dimensions are 7007001900mm, and mechanical test reports and video factory inspections can be provided.

Servo Motor Press Brakes PBA Press Brake with Servo Motor System

A servo motor is a type of electric motor used for servo mechanisms, capable of precise position or speed control through feedback control elements such as optical encoders or resolvers. The servo system consists of an actuator (controller), control device (servo amplifier), and drive and sensing devices. The controller issues action commands, the servo amplifier controls the motor movement based on command and feedback signals, and the drive and sensing devices provide power to the controlled object and detect its status. Servo systems achieve precise control by minimizing the error between the control result and the target value, with feedback mechanisms playing a critical role. Typically, encoder sensing is used to sense motor rotation and provide feedback, or high-precision control is achieved through external devices such as linear encoders.

This Press Brake's worktable is equipped with mechanical deflection compensation function, effectively improving bending accuracy and stability. With parameter and configuration optimization, this model has enhanced functionality and easier operation. It adopts high-frequency valve control technology, featuring excellent dynamic response and high precision characteristics. Additionally, this model supports load-sensitive adjustment, further enhancing energy efficiency and stability, providing users with efficient bending processing solutions.

PBC Press Brake with Servo Motor System

The PBC series CNC Press Brake innovates in performance, hydraulic systems, and functionality.

Performance Innovation Utilizing a new rigid structural design, optimized through finite element analysis, minimizes the impact of frame-slider deformation on workpiece quality. Applying high-precision bidirectional adjustment mechanical deflection compensation, coupled with the use of high-precision molds, effectively improves workpiece bending accuracy and stability.

Innovative Hydraulic System Utilizing SVP (Servo Pump) hydraulic system control technology, the main motor employs a servo motor instead of a conventional AC motor, combined with a small-displacement oil pump, achieving high-speed, efficient, and low-energy consumption operation of the machine tool. The PBC model operates faster and consumes less electricity, with a comprehensive energy-saving rate of about 50%.

Functional Innovation Replacing ordinary quick clamps with multi-functional quick clamps adds secondary loading and unloading mold functions, reducing mold replacement time and operational intensity, improving mold replacement efficiency. The rear material stopper adopts special materials and heat treatment methods, enhancing hardness and wear resistance, equipped with scale display, enhancing positioning accuracy and stability. Moreover, equipped with a newly designed aluminum alloy front support bracket, freely adjustable in height, adaptable to different molds and workpieces, effectively protecting the surface of the sheet, and providing a better user experience.

Special Press Brake Models WAD Press Brake with delem DA-66T Control System

The DA-66T, part of the DA-Touch 2D modular press brake control series, represents a high-end solution for press brake operations. Its advanced features include 2D programming with automatic bend sequence calculation and collision detection, along with full 3D machine setup for comprehensive feedback on product feasibility and handling. With optimized control algorithms, seamless integration capabilities, and user-friendly Delem touch navigation, the DA-66T ensures enhanced efficiency, productivity, and versatility in press brake operations.

MB8 Press Brake with delem DA-60series Control System

The DA-66T stands out with its intuitive touchscreen interface, available in 17" or 24" high-resolution color TFT screens, facilitating easy navigation. It offers USB peripheral interfacing, network connectivity, and advanced interfacing for high-end machine functions, ensuring seamless integration. Compatible with Modusys and equipped with offline software, it enables efficient production preparation for enhanced operational efficiency. The MB9 Press Brake is tailored for special sheet metal processing requirements, especially for irregular sheet metal bending applications.

PBS Press Brake with delem DA-53T Control System

The DA-53T offers a compact yet advanced touch control solution for synchronized press brakes. With its 10.1" high-resolution color TFT screen and intuitive Delem user interface, programming and operation are made easy. Capable of controlling up to 4 axes, it ensures efficient machine adjustment and minimal test bends, enhancing overall productivity and workflow optimization. The PBS Press Brake achieves high-level innovation in environmental protection, employing electro-hydraulic servo hybrid-driven bidirectional pump control hydraulic system to synchronize cylinder control, achieving high-precision bending, with a repetitive positioning accuracy of up to 0.005mm. Pump control technology replaces conventional valve control technology, eliminating throttling losses and overflow losses, resulting in low system heating and low noise. The hydraulic oil requirement is only one-fifth that of a valve-controlled machine of the same specifications, saving about 50% compared to traditional hydraulic systems.

PR6C Press Brake with delem Series Control System

PR6c adapts to various control systems in the delem series, and PR6C Press Brake itself is an efficient representative. For example, the PR6C225×3100 type 2250kN CNC sheet metal Press Brake adopts electro-hydraulic servo synchronization control technology and hydraulic convex compensation technology, integrated hydraulic system, realizing 8-axis control of bending slider Y1, Y2 position and rear material stopper X1, X2, Z1, Z2, R1, R2 position. The rapid downward speed of the slider is 120mm/s, the bending speed is 9mm/s, and the return speed is 80mm/s. The positioning accuracy of the bending slider is 0.005mm, and the repeat positioning accuracy of the rear material stopper front and rear position is 0.005mm.

Conclusão

The introduction of different Press Brake models and operating systems demonstrates the widespread application of Press Brakes in industrial production, covering various processing requirements and industry needs. Choosing the appropriate Press Brake model and operating system that suits one's production requirements is crucial for improving production efficiency and product quality. Overall, understanding the characteristics and functions of different models of Press Brakes and their operating systems can help businesses better select equipment that suits their production needs, thereby enhancing production efficiency, reducing production costs, ensuring product quality, and strengthening competitiveness. The choice of Press Brake and the configuration of the operating system directly impact production efficiency and product quality. Therefore, businesses should carefully consider when purchasing equipment, fully understand the characteristics of different models and operating systems, and make reasonable choices based on their own production needs to better improve production efficiency and product quality.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)