Common Defects in Sheet Metal Bending and Forming Processing and Measures to Address Them

In the manufacturing industry, sheet metal bending and forming is an important processing means to realize various shapes through plastic deformation of thin and medium sheet materials.

However, in practice, sheet metal bending and forming often faces various quality defects, such as bending rebound, bending cracks and bending indentation, etc. These problems not only affect product quality, but also may lead to waste of resources and low productivity. Therefore, this paper will discuss the causes and solutions of these common defects, with a view to providing effective quality control solutions and optimization methods for sheet metal bending and forming.

instruction

Sheet metal bending and forming, as a frequently used and vital processing method in the manufacturing industry, it plays an indispensable role in various industries. The process mainly involves the application of force by mechanical equipment to precisely bend thin and medium sheet materials to create a variety of components and structural forms that meet the design requirements. These components and structures are widely used in mechanical equipment, automobiles, construction, electronics and other fields, and their quality is directly related to the performance and safety of the final product.

During the process of sheet metal bending and forming, a variety of quality defects may occur, such as inaccurate bending angle, obvious bending marks, surface damage, cracks, deformation and so on. These defects, if not recognized and processed in time, will adversely affect the overall performance of the product, and may even be a potential safety hazard. Therefore, quality control in sheet metal bending and forming process is a key link to ensure product quality.

In order to improve the efficiency and product quality of sheet metal bending and forming, this paper will deeply analyze the quality defects that may occur during the processing and discuss the corresponding measures to solve them. This includes, but is not limited to, optimizing process parameters, selecting appropriate molds and materials, improving equipment accuracy, improving operator skills and strengthening process quality control. Through these measures, the generation of defects can be minimized in the production process, thus improving product reliability and market competitiveness.

Overview of Sheet Metal Bending & Forming Process

Working Principle and Classification

Sheet metal bending and forming is a key technology in the metalworking process, which mainly involves the bending and deformation of sheet metal to meet the design requirements of various industrial components and structures.

This process can usually be divided into two basic categories: free bending and depression bending. Free bending is accomplished by precisely controlling the movement of the upper mold on the bending machine so that the sheet metal is bent along a pre-designed bending line at the angle and radius specified in the drawing. This method requires precise positioning and adjustment of the mold to ensure the accuracy and repeatability of the bend.

Depression bending, on the other hand, is a more traditional and simpler method. In this process, the upper die of the bending machine is pressed down to its lowest position, where the combined pressure between the upper and lower dies acts on the sheet metal to create the desired bending deflection. This method is typically used for thicker and heavier plates, as it provides more uniform stress distribution and greater bending stability. Whether free bending or compression bending is used, the aim is to achieve accurate forming of sheet metal parts to ensure that they can meet the requirements of the engineering design, as well as to ensure that the process is efficient and cost-effective.

Common defects and their causes

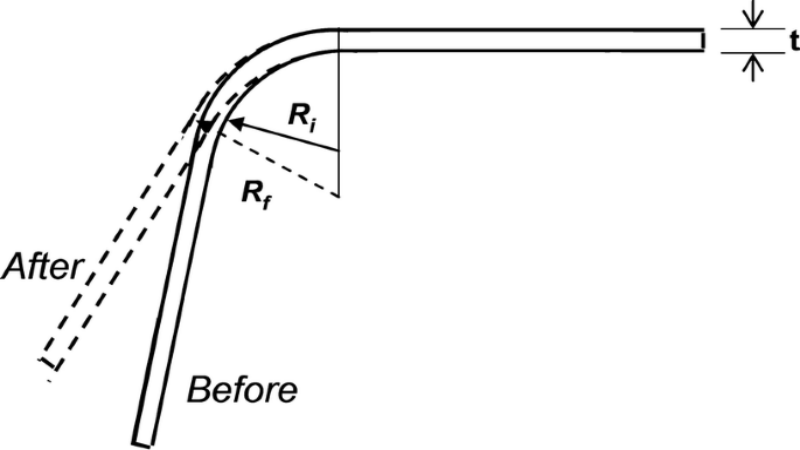

Bending springback

During the bending and forming process, the neutral layer of the sheet metal will be affected by elastic deformation, causing the size and shape of the finished product to deviate from the design requirements. The main reasons for this include the elastic properties of the neutral layer and improper processing of the material.

Solution measures

- When bending deformation, the elastic deformation of the plate will increase the amount of rebound due to the elastic deformation of the plate. Therefore, the plate should be annealed before bending, especially for materials that have been cold work hardened, to improve the internal stress organization of the plate, to reduce the rebound problem during processing effectively.

- After the sheet metal bending process is formed, the bending parts will recover due to the elastic deformation of the plate, resulting in a slightly larger bending inner diameter and angle than the theoretical value. In order to minimize the effect of this rebound, you can appropriately increase the size of the deformation in the bending process, so that the final product meets the design requirements.

- Using a small inner diameter of the upper mold for multiple point bending, through multiple bending deformation can effectively reduce or eliminate the rebound phenomenon, and improve the accuracy and stability of bending and forming.

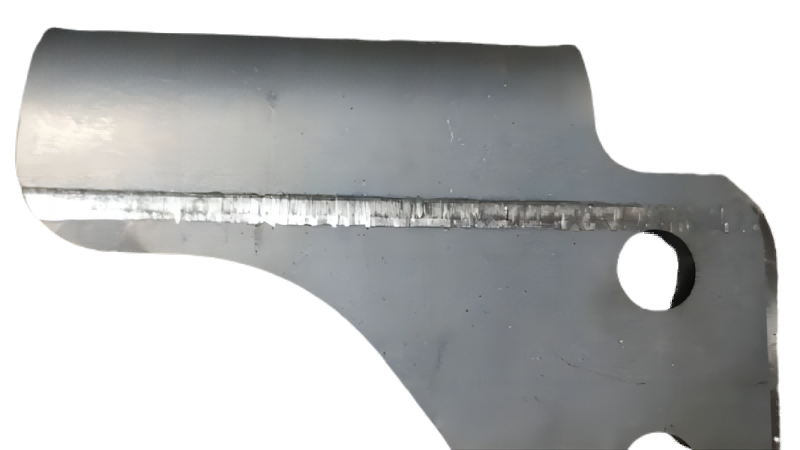

Bending cracks

During the bending and forming process, the neutral layer of the sheet metal will be affected by elastic deformation, causing the size and shape of the finished product to deviate from the design requirements. The main reasons for this include the elastic properties of the neutral layer and improper processing of the material.

Solution measures

- Adjust the die clearance as well as the uniformity, so that the quality of the section of punching and shearing can be improved to ensure that the section is smooth and straight, and to avoid the appearance of defects such as burrs and cracks.

- Take the direction of raw material rolling as the basis, and utilize the nesting software to carry out reasonable scheduling. If the bending direction is the same as the raw material grain direction, the minimum value of the bending radius should be increased appropriately; if the bending direction is perpendicular to the direction of the raw material grain, the minimum value of the bending radius should be reduced appropriately. Ensure that the angle between the direction of the raw material grain and the bending line should generally be about 60 °, the minimum above 30 °.

- At the position where multiple bending edges intersect, stop-crack holes should be arranged according to the permissible conditions. The size of the stop-crack hole should be greater than or equal to the thickness of the raw material plus the inside diameter of the bend, when the bending line appears at right angles, increase the width of the stop-crack groove should be greater than two times the thickness of the raw material plus the inside diameter of the bend, as shown in Figure 3.

- bending process equipment in accordance with the requirements of the time node lubrication and maintenance, reduce flow resistance, to ensure stable operation of the equipment and long-term use of continuity.

Bending indentation

During the bending process, the pressure of the upper and lower molds will leave indentations on the surface of the plate, especially for products with high appearance requirements, and these indentations may become quality defects.

Solution measures

- Lengthen the upper mold tire and increase the radius of the fillet at the end of the mold;

- Increase the width of the groove of the lower die fixture as far as possible, so that the inner diameter of the sheet metal part becomes bigger after bending and forming, and the extrusion of the workpiece in the groove of the lower die can be reduced;

- The lower die is designed as a roller type V-shaped die, as shown in Figure 5, when the upper die is pressed down, the sheet will generally be rotated in a driven manner, so that the workpiece and the lower die to maintain full and complete contact with the lower die, effectively avoiding the emergence of bending indentation;

- In the upper part of the sheet and the lower die position padding thickness of 0.1 ~ 0.5mm rubber skin or non-indentation film, to avoid or reduce the bending indentation.

Conclusão

In this paper, the common defects in the sheet metal bending and forming process have been discussed in depth, and corresponding measures have been proposed to solve the problem. The article emphasizes the importance of optimizing process parameters and upgrading equipment technology to ensure the quality of forming and processing. At the same time, through the implementation of effective quality control strategies, the quality stability of products can be improved, thus reducing production costs and enhancing the market competitiveness and economic benefits of enterprises. In actual production, enterprises should adjust the process parameters according to the specific situation, constantly optimize the production process, while focusing on the technical update and maintenance of equipment to ensure the smooth progress of the processing. In addition, strengthening quality control training and improving the quality awareness and technical level of employees are also important means to improve product quality stability and reduce the defect rate. Through the above measures, enterprises can improve production efficiency and reduce costs under the premise of ensuring product quality, thus enhancing market competitiveness and realizing sustainable development.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.