CNC Shearing Machine

General Features

The CNC shearing machine is a machine that uses one blade to reciprocate linear motion relative to the other blade to cut the plate. By means of a moving upper blade and a fixed lower blade, a reasonable blade gap is used to apply shearing force to metal plates of various thicknesses, so that the plates can be broken and separated according to the required size. Shearing machine is a kind of forging machinery, whose main function is the metal processing industry. Products are widely used in aviation, light industry and metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment required.

- Adopt Series QC12Y type structure,with economic type special-purpose digital controlsystem;

- Back gauge position is displayed in real time;

- Multi-stages program,automatic operation of back gauge,continuous positioning,realization the automatic adjustment of the position of back gauge with excellent lprecision;

- Shear time calculation,display the amount of shear in real time,record the position ofback gauge,program and parameters in power break;

- Back gauge use imported ball screw,which improve the precision of the positioning ofback gauge and also the precision of the processing of the machine.

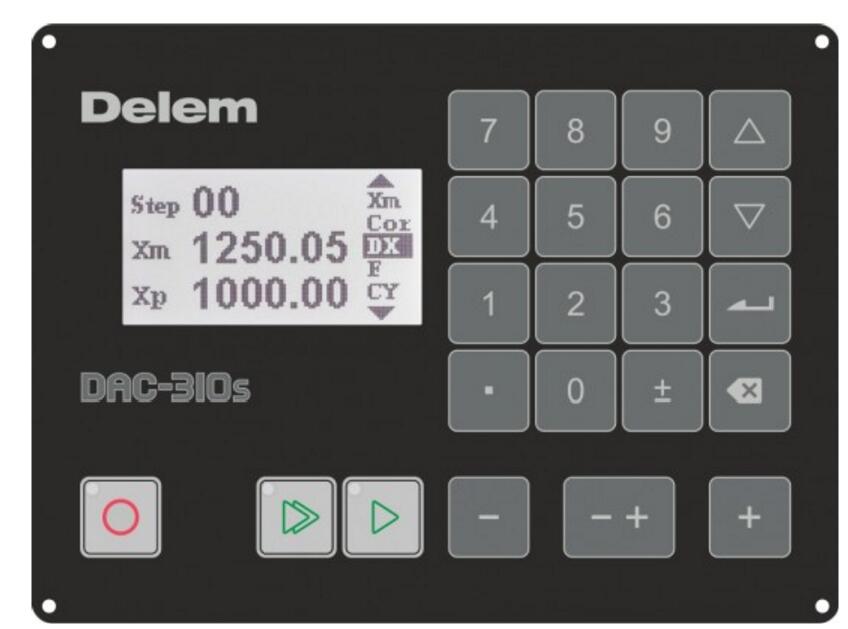

DAC310S CNC Controller From ESTUN

Controller Data

- High-definition LCD display, 128x64 pixels

- Backgauge control

- Knife edge clearance control

- Cutting stroke control

- The actual position of the back gauge is displayed synchronously with the programmed value

- Cut count

- 100 program steps

- Panel mount

- Servo control / frequency conversion speed control / two-speed AC motor control

CNC Shearing Machine Working Video

The Delem DAC310S CNC control system and the position encoder form a closed-loop control system with fast speed, high precision and good stability, which can accurately guarantee the displacement dimensional accuracy of the back gauge. At the same time, the numerical control system has a variety of additional functions such as compensation and automatic detection.

Componentes principais

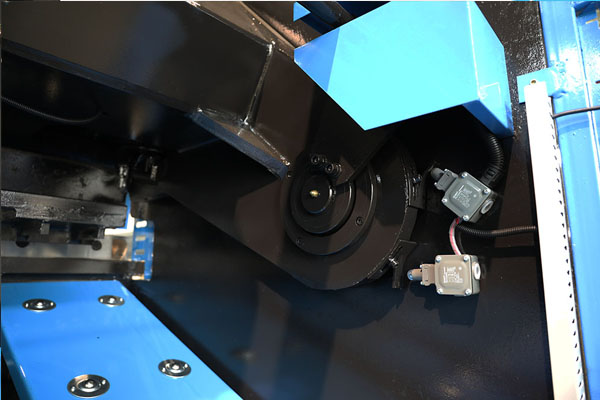

Estação de ângulo

Back Gauge(Optional)

It comprises a rack, the plate provided with the slide feeding rack, the rack is provided with one side of a support shaft, said support shaft is provided with two parallel triangular brackets, the bracket is provided below the upper and lower cylinders, The bottom end of the vertical cylinder connected to the frame, the upper surface of the piston rod with hinged top and bottom of the cylinder bracket, the bracket can be driven up and down in a cylinder around the support shaft rotated counter-clockwise to a horizontal position; the bracket The upper side is provided with a row of rollers, said rollers have 5-20, the adjacent distance between the rollers 10 to 50 cm. The utility model means you can make the process of sheet metal shear deformation is not easy to ensure cutting accuracy.

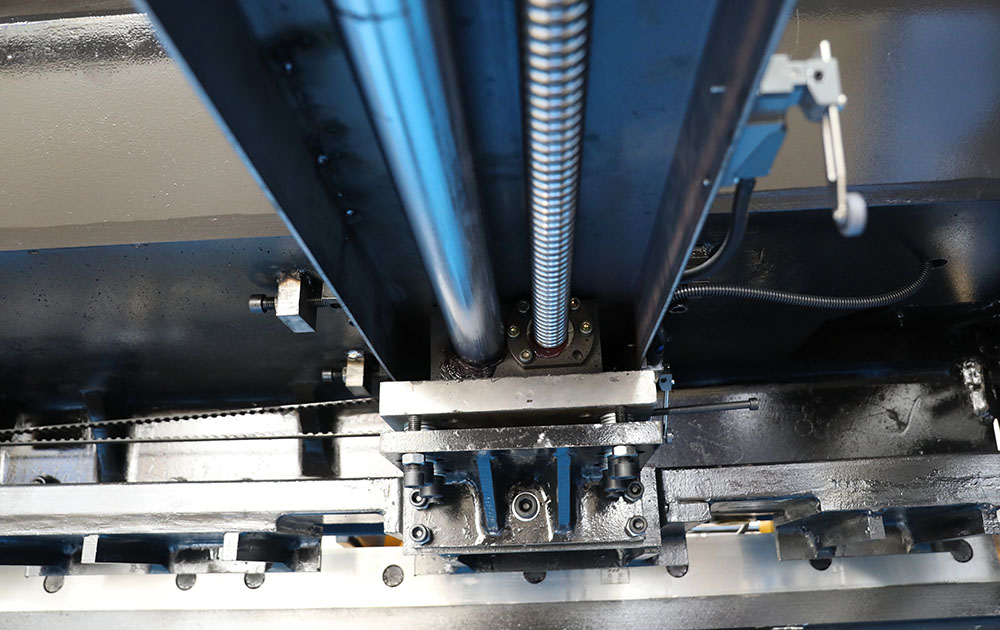

Parafuso de esferas

High-Precision back guage device , fine ball screw and polished rod structure , high performance motor drive ,ensuring the positioning accuracy , unique timing transmission mechanism , reliable and stable

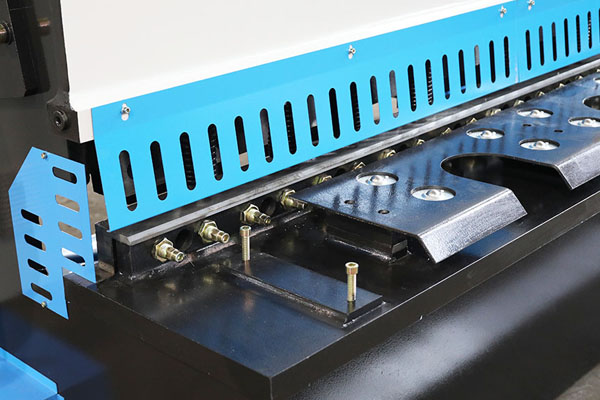

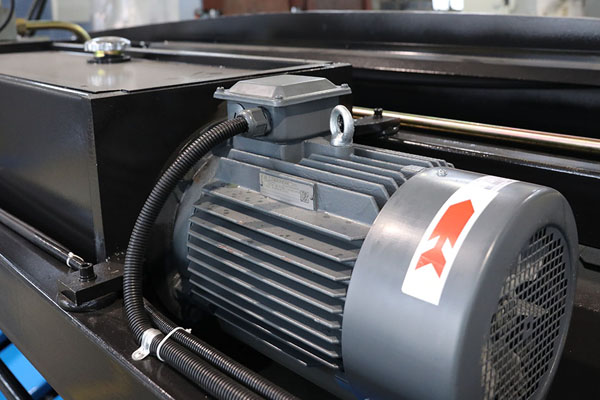

OTHER COMPONENTS

Dados técnicos

| Seri-al NO. | Nome | Numerical value | Unidade | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4x1500 | 4x1600 | 4x2500 | 4x3200 | 4x4000 | 4x6000 | 6x2500 | 6x3200 | 6x4000 | 6x6000 | 8x2500 | 8x3200 | 8x4000 | 8x6000 | 10x2500 | 10x3200 | 10x4000 | 10x4000 | |||||||||||||||||||||||

| 1 | Max. Cutting Thickness | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | mm | ||||||||||||||||||||

| 2 | Max.Cutting Length | 1500 | 1600 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 4000 | mm | ||||||||||||||||||||

| 3 | Strength of sheared plate | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | N/m㎡ | ||||||||||||||||||||

| 4 | Cutting Angle | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°40 | 1°40 | 1°40 | 1°40 | |||||||||||||||||||||

| 5 | Number of strokes | 44483 | 44483 | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 | 8-12 | 10 | 14 | 14 | 14 | 14 | 10 | 14 | 14 | 14 | 14 | Hits/min | ||||||||||||||||||||

| 6 | Length of Cutter Blade(A) | 1600 | 1600 | 2600 | 3300 | 4100 | 6100 | 2600 | 3300 | 4010 | 6240 | 2600 | 3300 | 4100 | 6100 | 2600 | 3300 | 4100 | 4100 | mm | ||||||||||||||||||||

| 7 | Height of working table above the ground (C) | 800 | 800 | 800 | 800 | 800 | 800 | 10-700 | 10-700 | 10-700 | 10-700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | mm | ||||||||||||||||||||

| 8 | Backgauge Range of X Axis | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | mm | ||||||||||||||||||||

| 9 | Main Motor | Type | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | ||||||||||||||||||||

| Power | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | KW | |||||||||||||||||||||

| Rotate Speed | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | R/MIN | |||||||||||||||||||||

| 10 | Gear Pump | Type | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP1-25-10R | CP1-25-10R | CP1-25-10R | CP1-25-10R | NBZ-G25F | NBZ-G25F | NBZ-G25F | NBZ-G25F | CP1-32-P-10R | CP1-32-P-10R | CP1-32-P-10R | CP1-32-P-10R | ||||||||||||||||||||

| Norminal Flow | 10 | 10 | 10 | 10 | 10 | 10 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 32 | 32 | 32 | 32 | Ml/r | |||||||||||||||||||||

| Norminal Pressure | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | Mpa | |||||||||||||||||||||

| 11 | Back-gauge motor | Type | YS7134 | YS7134 | YS7134 | YS7134 | YS7134 | YS7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | ||||||||||||||||||||

| Power | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | KW | |||||||||||||||||||||

| Rotate Speed | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | R/min | |||||||||||||||||||||

| 12 | External Dimensions | Comprimento | 2320 | 2320 | 2820 | 3580 | 4630 | 6630 | 3030 | 3730 | 4800 | 6430 | 3050 | 3730 | 4530 | 6630 | 2830 | 3830 | 4630 | 4630 | mm | |||||||||||||||||||

| Width | 1420 | 1420 | 1520 | 1620 | 1850 | 1850 | 1700 | 1700 | 1850 | 2150 | 1700 | 1700 | 1700 | 1850 | 1950 | 1950 | 1950 | 1950 | ||||||||||||||||||||||

| Height | 1500 | 1500 | 1850 | 1900 | 1700 | 1700 | 1620 | 1620 | 1700 | 2600 | 1620 | 1620 | 1620 | 1700 | 1850 | 1850 | 1850 | 1850 | ||||||||||||||||||||||

| 14 | Machine Weight | 2600 | 2600 | 3600 | 4800 | 6600 | 8400 | 4600 | 5600 | 7600 | 14300 | 5500 | 6300 | 8200 | 19000 | 7200 | 7800 | 9200 | 9200 | Kg | ||||||||||||||||||||

| 15 | Power requirement | 380V (-15%,+15%) 50Hz ,3PH | ||||||||||||||||||||||||||||||||||||||