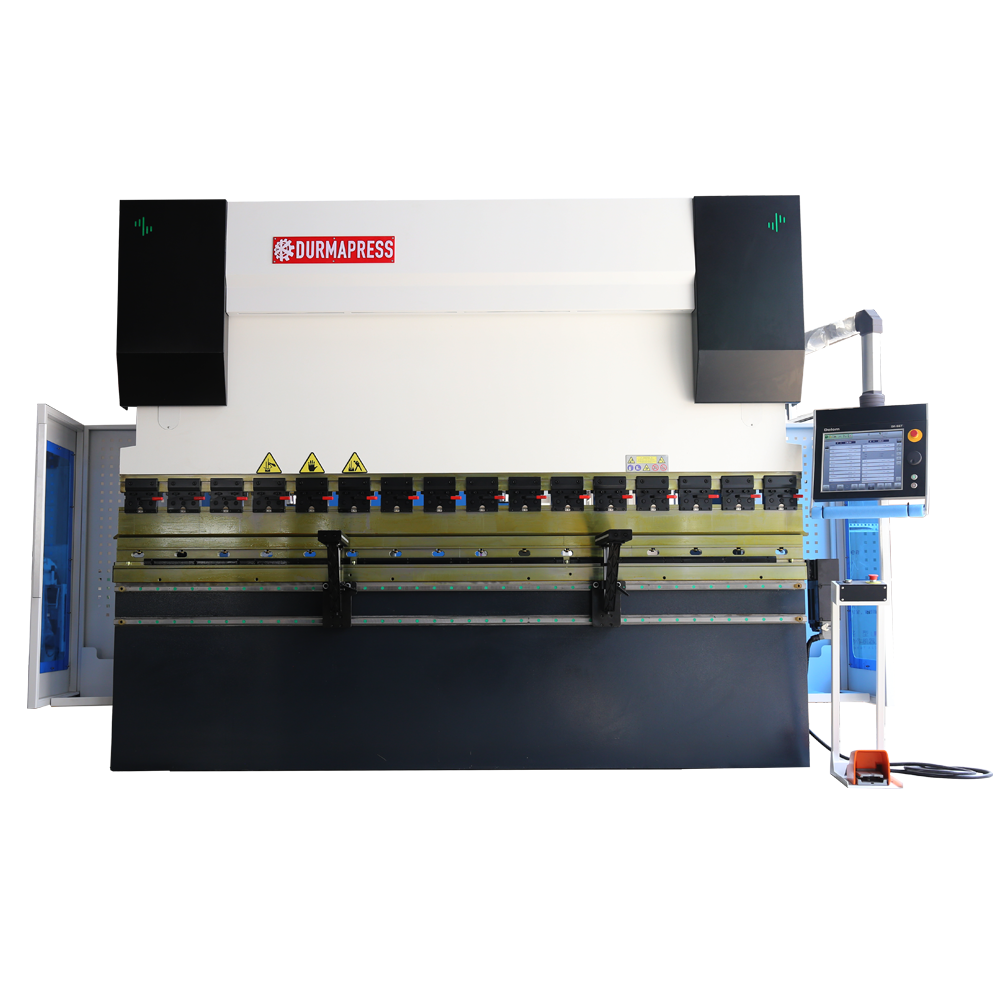

Prensa dobradeira CNC DA66T

Geral Caraterísticas

Máquina de prensa dobradeira CNC electro-hidráulica DA66T

- Estrutura robusta em chapa de aço soldada, aliviando as vibrações

- Transmissão superior estável e fiável

- Função de carga excêntrica excecional, a folha pode dobrar-se em qualquer ponto da matriz inferior, não necessariamente no meio

- Sincronização servo proporcional electro-hidráulica para garantir a precisão das operações repetidas

- Pode ser controlado em qualquer ponto do curso, com repetibilidade até +/-0,01 e paralelismo até 0,02

- A mesa de trabalho inferior adopta a compensação da deflexão ou a matriz superior está equipada com um mecanismo de compensação da deflexão

- Equipado com o sistema CNC Dutch Delem DA66T, régua de grelha, grupo de válvulas do sistema hidráulico Rexroth, servomotor e outros acessórios de marcas bem conhecidas, com bom desempenho

Controlador CNC DA66T De Delem

Dados do controlador

- Modo de programação com ecrã tátil gráfico 2D

- Visualização 3D em simulação e produção

- TFT a cores de alta resolução de 17

- Conjunto completo de aplicações Windows

- Compatibilidade Delem Modusys (escalabilidade e adaptabilidade do módulo)

- USB, interface periférica

- Apoio a aplicações específicas do utilizador no âmbito do ambiente multitarefa dos controladores

- Interface de dobragem e correção do sensor

- Software Profile-TL offline

Inquérito agora para o preço do agente

Estrutura da máquina

O modelo de máquina de prensa dobradeira eletro-hidráulica CNC DA66T é a prensa dobradeira CNC da série MB8 com uma estrutura soldada de placa de aço sólida, tensão de alívio de vibração; excelente função de carga excêntrica, a folha de metal pode dobrar em qualquer ponto da matriz inferior, não precisa estar no meio; o servo proporcional hidráulico eletrônico é sincronizado para garantir a precisão de operações repetidas; pode ser controlado em qualquer ponto dentro do curso, com uma repetibilidade de +/- 0,01 e um paralelismo de 0,02.

Ferramentas de prensagem

O punção superior standard e a matriz inferior em duplo V foram especialmente concebidos para dobrar chapas metálicas. Podem ser selecionadas mais ferramentas de prensagem de acordo com a sua utilização prática. Os valores do material e do grau HRC47 estão marcados no mesmo

Balança traseira

Utilizamos o fuso de esferas PMI de Taiwan e a guia linear para garantir o movimento do eixo X com maior precisão do que utilizando a haste. E o backgauge adopta mecanismo de correia dentada e roda que é controlado por servo motor em vez de motor de passo. A altura do dedo do medidor de costas pode ser ajustada manualmente. No total, existem TRÊS peças de dedos de medição para posicionamento.

OUTROS COMPONENTES

DADOS TÉCNICOS

| Seri-al NO. | Nome | Valor numérico | Unidade | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40T/2500 | 63T/2500 | 63T/3200 | 63T/4000 | 80T/2500 | 80T/3200 | 80T/4000 | 100T/2500 | 100T/3200 | 100T/4000 | 125T/3200 | 125T/4000 | 160T/3200 | 160T/4000 | 200T/3200 | 200T/4000 | 250T/3200 | 250T/4000 | 300T/3200 | 300T/4000 | 300T/6000 | 400T/3200 | 400T/4000 | 400T/6000 | 500T/6000 | 600T/6000 | |||||||||||||||||||||||||||||||

| 1 | Eixo de controlo CNC | 3+1 eixos ( Y1, Y2, X + V Coroamento ) Eixo R opcional | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Força nominal | 4000 | 630 | 630 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1250 | 1250 | 1600 | 1600 | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | 5000 | 6000 | KN | ||||||||||||||||||||||||||||

| 3 | Comprimento de dobragem | 2500 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 6000 | 3200 | 4000 | 6000 | 6000 | 6000 | mm | ||||||||||||||||||||||||||||

| 4 | Curso do cursor | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 200 | 200 | 250 | 320 | 320 | 320 | 320 | 320 | mm | ||||||||||||||||||||||||||||

| 5 | Luz do dia | 430 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 470 | 500 | 500 | 540 | 560 | 560 | 560 | 560 | 560 | |||||||||||||||||||||||||||||

| 6 | Profundidade da garganta | 250 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 520 | 520 | 280 | 280 | 400 | 400 | 400 | 400 | 470 | 500 | |||||||||||||||||||||||||||||

| 7 | Largura da mesa | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 160 | 160 | |||||||||||||||||||||||||||||

| 8 | Altura da mesa de trabalho | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 3150 | 1000 | 1000 | 1000 | mm | ||||||||||||||||||||||||||||

| 9 | Velocidade de trabalho | Velocidade de carga total | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 120 | 130 | 120 | 110 | 110 | 150 | 150 | 90 | 85 | 85 | 85 | 85 | 85 | Mm/seg | |||||||||||||||||||||||||||

| Velocidade de trabalho | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 9 | 9 | 9 | 9 | 9 | 0-9.5 | 0-9.5 | 9 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | ||||||||||||||||||||||||||||||

| Velocidade de retorno elevada | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 95 | 95 | 95 | 95 | 95 | 110 | 110 | 100 | 85 | 85 | 85 | 75 | 85 | ||||||||||||||||||||||||||||||

| 10 | Backguage CNC | Curso máximo do eixo X | 400 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 500 | 500 | 800 | 550 | 550 | 550 | 550 | 550 | MM | |||||||||||||||||||||||||||

| Curso máximo do eixo R | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 150 | 150 | 200 | 150 | 150 | 150 | 150 | 150 | MM | |||||||||||||||||||||||||||||

| Bloco de dedos | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 6 | 6 | 6 | PC | |||||||||||||||||||||||||||||

| 11 | Capacidade | Pressão hidráulica | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | Bar | |||||||||||||||||||||||||||

| Potência do motor | 5.5 | 5.5 | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 22 | 30 | 30 | 30 | 37 | 45 | Kw | |||||||||||||||||||||||||||||

| Capacidade do depósito de óleo | 200 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Lts | |||||||||||||||||||||||||||||

| 12 | Peso da máquina | 2300 | 4800 | 5400 | 6200 | 5800 | 6300 | 7800 | 8500 | 8500 | 9600 | 8800 | 9800 | 10200 | 10500 | 14000 | 15000 | 15500 | 16500 | 16800 | 17800 | 24500 | 23000 | 26500 | 32500 | 40000 | 6550 | Kgs | ||||||||||||||||||||||||||||

| 13 | Dimensão global | Comprimento | 2850 | 4550 | 4550 | 4550 | 2850 | 3550 | 4550 | 2850 | 3650 | 4550 | 3850 | 4550 | 3550 | 4550 | 3550 | 4360 | 4350 | 4350 | 3550 | 4550 | 6350 | 3850 | 4550 | 6550 | 6550 | 2350 | mm | |||||||||||||||||||||||||||

| Largura | 1860 | 1950 | 1950 | 1950 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 3580 | ||||||||||||||||||||||||||||||

| Altura | 1900 | 2150 | 2150 | 2150 | 2250 | 2250 | 2250 | 2450 | 2450 | 2450 | 2480 | 2480 | 2680 | 2680 | 2880 | 2880 | 2980 | 2980 | 3180 | 3180 | 3200 | 3180 | 3180 | 3180 | 3380 | |||||||||||||||||||||||||||||||

| 14 | Necessidade de energia | AC 220V~480V,3ph,50/60HZ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||