CNC Bending Follower: Comprehensive Introduction and Application of Precision Bending Control Solution

O CNC bending follower is an advanced automated bending follower for today's industry, designed to dramatically improve productivity and accuracy. The design concept incorporates a number of key benefits that enable it to excel in a variety of industrial environments and application scenarios.

Technical Specifications and Benefits

The CNC Bending Follower is designed to provide superior support for automated bending operations. Firstly, it features a high-precision control system and advanced sensor technology to ensure that every bending operation is accurately met, thus ensuring consistent and high levels of product quality. Secondly, the machine is constructed with a durable main frame and high-quality materials to provide a solid guarantee for long-term stable operation and to cope with high-intensity use in industrial production. In addition, the CNC bending follower adopts a low-power consumption design, which reduces energy consumption and operating costs, in line with the modern industry's emphasis on energy saving and environmental protection. These advantages make CNC bending followers become the key equipment in modern industrial automation, not only to enhance production efficiency but also to significantly improve the accuracy and consistency of product processing, for enterprises to bring significant economic benefits and market competitiveness.

Next, we will explore in-depth the detailed components and functions of CNC bending followers, as well as their rich customization options, demonstrating their diverse applications and excellent performance in different industries and application scenarios.

Choosing the right CNC bending follower in the sheet metal processing industry is crucial as it directly affects productivity and process quality. Floor Type and Combined Type CNC Bending Followers are two common choices, each with unique operating characteristics, maintenance requirements, and different cost considerations.

Floor Type CNC Bending Followers

Operation and Maintenance

- OPERATION: Floor Type followers may require more operating space due to their fixed installation on the floor. Once installed, its stability allows the operator to perform high-precision sheet metal bending with greater confidence.

- MAINTENANCE: The design often has easily accessible maintenance points, but due to its large size and fixed nature, additional maintenance tools or equipment may be required to service and maintain the unit.

Cost

- INITIAL INVESTMENT: Ground-based followers typically have a high initial investment cost due to their rugged construction and high load-bearing capacity.

- OPERATING COSTS: In long term operation, due to high stability and durability, fewer repairs and replacement parts are usually required, resulting in lower operating costs.

Combined Type CNC Bending Followers

Operation and Maintenance

- OPERATION: Combined Type followers are easier to operate due to their flexibility and adjustability. The operator can quickly adjust the machine to different sheet metal processing needs as needed.

- MAINTENANCE: The modular design makes maintenance easier. When a component needs to be replaced or repaired, it can be removed and replaced individually without shutting down the entire system.

Cost

- INITIAL INVESTMENT: While combination followers offer advantages in terms of flexibility, their complex construction and versatility may result in a slightly higher initial investment cost.

- Running Costs: Due to its flexibility and modular design, more maintenance and adjustments may be required, which may add some running costs. However, these costs may be compensated by increased productivity and reduced downtime.

Technical specifications and advantages

Technical parameters

- Size and weight: compact design, adaptable to different working spaces.

- Materials: High-strength materials are used to ensure stability and durability.

- Operating Temperature Range: Wide range of operating temperatures, suitable for a variety of environments.

- Power requirements: low power consumption design, energy saving and environmental protection.

Advantage

- High precision: precise control system and sensors ensure high quality bending operation.

- Durability: Rugged body frame and high quality materials for long term stable operation.

- Easy maintenance: modular design simplifies the maintenance and repair process.

- Low power consumption: energy saving and environmental protection, reduce operation cost.

Detailed components and functions

Estrutura principal

- Main frame: sturdy frame structure supports overall stability and precise control.

- Control system: advanced control technology to ensure operational precision and reliability.

- Sensors: high sensitivity sensors to monitor and adjust the bending process in real time.

- Power System: High-efficiency power system to ensure continuous and stable work output.

Optional features

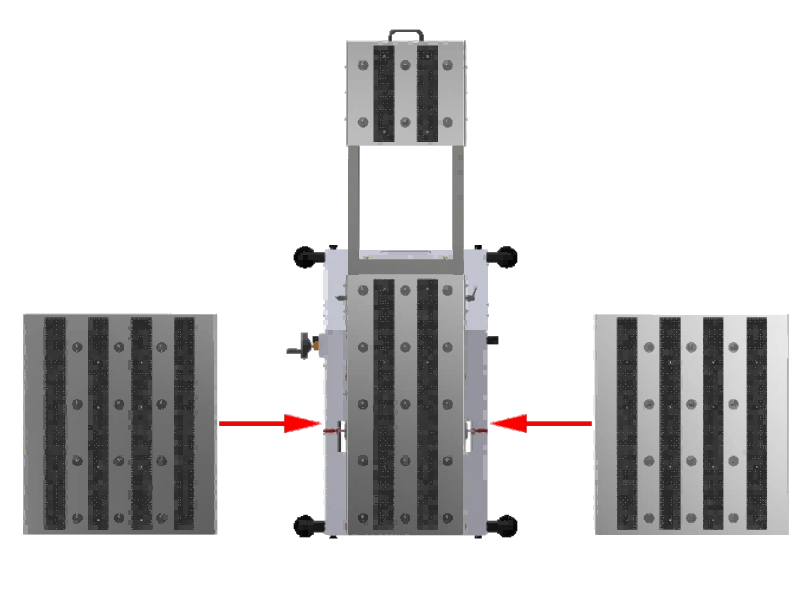

Common optional features include an expandable worktable, a rotating table, an automatic flattening function, and AMADA RG These options can be customized to meet specific requirements, offering enhanced flexibility and efficiency in various manufacturing applications.

Applications

Widely used in a variety of industries, it demonstrates its superior performance and versatile features in the following scenarios:

Furniture Manufacturing

In the furniture manufacturing industry, the CNC Bending Follower can be used to produce metal parts for various furniture applications, such as support structures for tables and chairs or metal door panels for closets. Its high-efficiency power system and adjustable axial design can meet the needs of processing metal parts of different sizes and shapes, enhancing the flexibility and efficiency of furniture production lines.

Actual benefits and user experience

- Increase productivity: automated operation improves production speed and accuracy.

- Reduces operational risk: Reduces human error and safety risks.

- Improve product quality: ensure consistency and quality standards for each product.

- efficiency and safety:

- High degree of automation: reduce manual intervention and improve production line efficiency.

- Safety protection measures: equipped with perfect safety protection measures to guarantee the safety of operators.

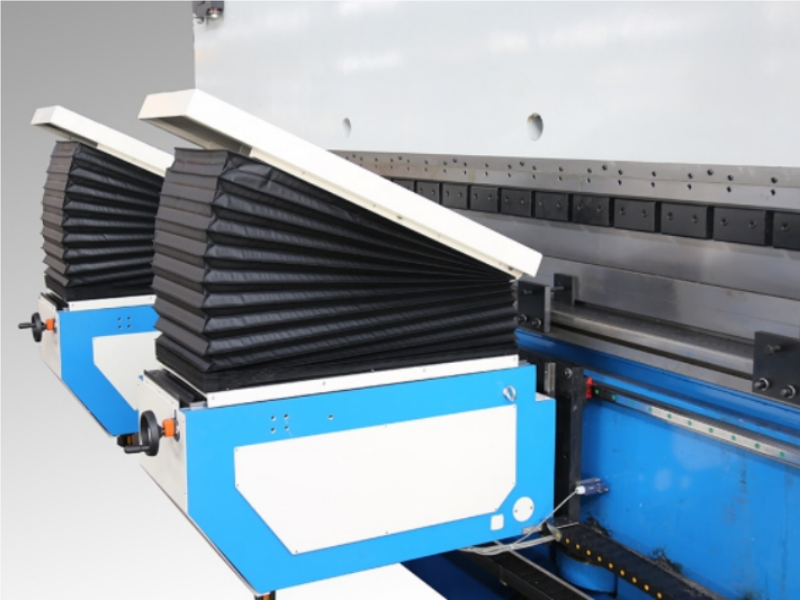

Multiple folding machines are used in series

Press brake followers CNC bending followers show their excellent adaptability and efficiency in the case of tandem use of multiple folding machines. By connecting several folding machines, the CNC Bending Follower can continuously and efficiently bend large sheets, thus significantly increasing the overall production capacity of the line. This tandem use not only saves human resources but also reduces operator labor intensity by automating the operation process, ensuring product consistency and quality stability.

Suitable for all brands of press brakes

Press brake followers CNC bending followers show their excellent adaptability and efficiency in the case of tandem use of multiple folding machines. By connecting several folding machines, the CNC Bending Follower can continuously and efficiently bend large sheets, thus significantly increasing the overall production capacity of the line. This tandem use not only saves human resources but also reduces operator labor intensity by automating the operation process, ensuring product consistency and quality stability.

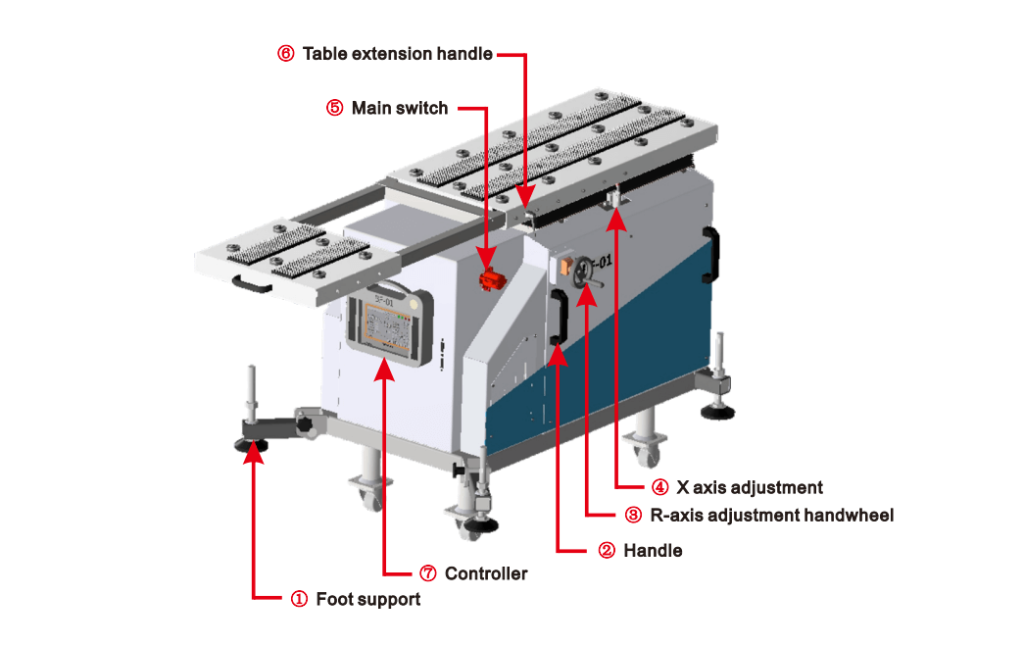

Safety and ease of operation

CNC bending follower The main switch is designed for easy and safe operation. The operator can start or shut down the equipment through simple steps, which effectively reduces the safety risk during operation. In addition, the design of the brush table can effectively prevent the plate from scratching, sliding or falling during the bending process, ensuring the integrity of the plate surface and processing quality.

Improve productivity and accuracy

The CNC Bending Follower's adjustable X and R axes allow it to precisely match different sizes and shapes of tools, ensuring accurate and consistent bending angles. This precise control capability greatly improves the processing efficiency during the production process, reduces debugging time and scrap rate, and at the same time improves the production speed and shipping cycle of the products, which brings obvious economic benefits and market competitiveness to the enterprise.

press brake follower CNC bending follower Through its safety, high efficiency, flexibility and accuracy, it has become an indispensable and important equipment in modern industrial production, providing reliable technical support and solutions for enterprises in the face of complex bending processing needs.

Summary

The Bending Follower CNC is more than just a machine, it represents the latest achievement in industrial automation and is a key tool for companies to increase productivity, reduce costs and improve product quality. Its advanced technology and wide range of customization options allow it to provide precise solutions for the specific needs of different industries. In the field of press brakes, the CNC bending follower plays a particularly important role. With its precise control system and highly sensitive sensors, it ensures that every bending operation meets the desired accuracy, thus dramatically improving the efficiency of the production line and the quality of the product. Its modular design simplifies the maintenance and repair process, reduces downtime, and further enhances the stability and reliability of the production line. the CNC bending follower not only improves the efficiency of a single press brake, but also demonstrates excellent synergistic capabilities in scenarios where multiple press brakes are used in tandem, injecting new impetus and vitality into the industrial development of the industrial press brake industry.

Call to Action

If you are interested in the Bending Follower CNC bending follower or have any questions, please feel free to contact our team for more information. We warmly welcome agents worldwide to join us in exploring the market potential and promoting the application of this innovative technology.

Through the above, I believe you have gained a more comprehensive understanding and appreciation of the unique value and advantages of the Bending Follower CNC in the field of industrial automation

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)