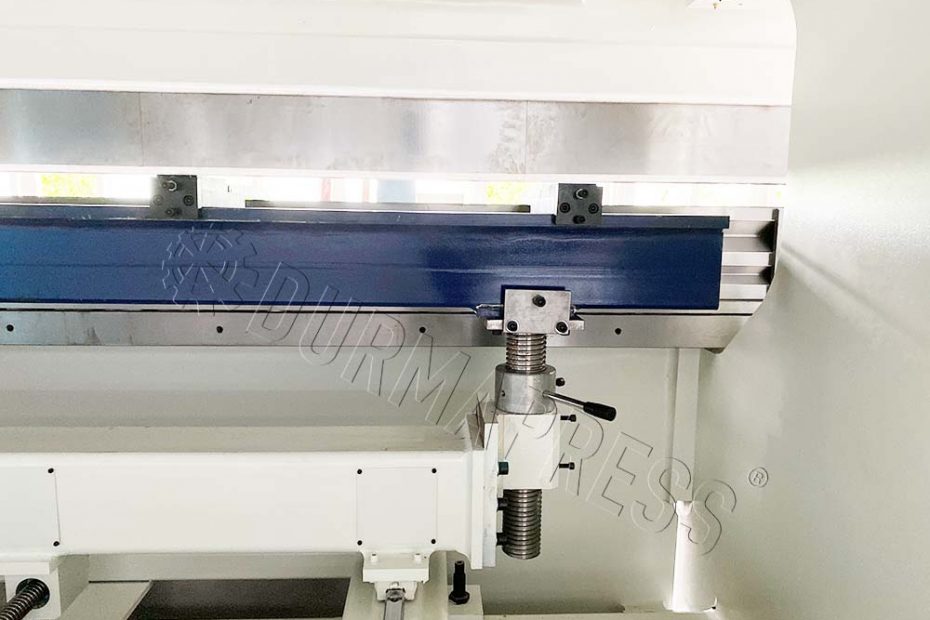

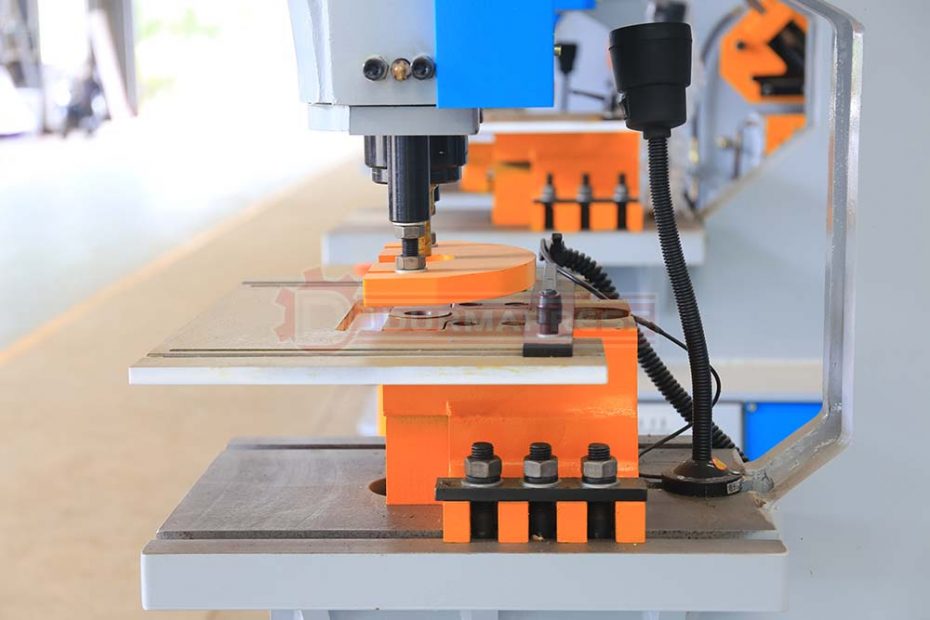

Bobinadeira de chapa universal CNC de grande porte para rolo superior

Bobinadeira de chapa universal CNC de grande porte Desempenho e caraterísticas: 1. Pré-flexão final de alta precisão Comprimento de borda reta de conjunto livre, o rolo superior diretamente pressão pré-flexão, pode completar a pré-flexão final de alta precisão. 2. controle NC, parâmetros de processo NC de alta eficiência de produção de produtos de rolamento, operação simples, eficiência muito melhorada. 3. Grande máquina de enrolamento de placa universal CNC Produtos de super precisão O rolo superior tem a forma de um tambor, e a parte inferior do rolo inferior é ajustada pelo suporte... Ler mais "Bobinadeira de chapa universal CNC de grande porte para rolo superior