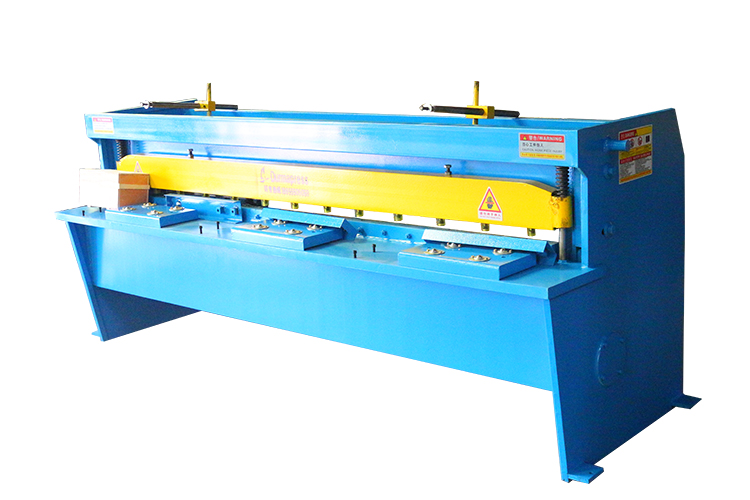

Descobrindo os pontos fortes das máquinas de cisalhamento de pêndulo hidráulico

A máquina de corte pendular hidráulica é um tipo especializado de corte hidráulico, concebido exclusivamente para o corte de movimentos em arco. Este padrão de movimento específico apresenta desafios técnicos durante a produção devido ao seu elevado nível de complexidade. Normalmente, é utilizada uma almofada para preencher a folga durante o funcionamento para garantir uma precisão de corte óptima, uma vez que o movimento em arco e o ângulo agudo da lâmina podem levar a um desgaste significativo da lâmina.