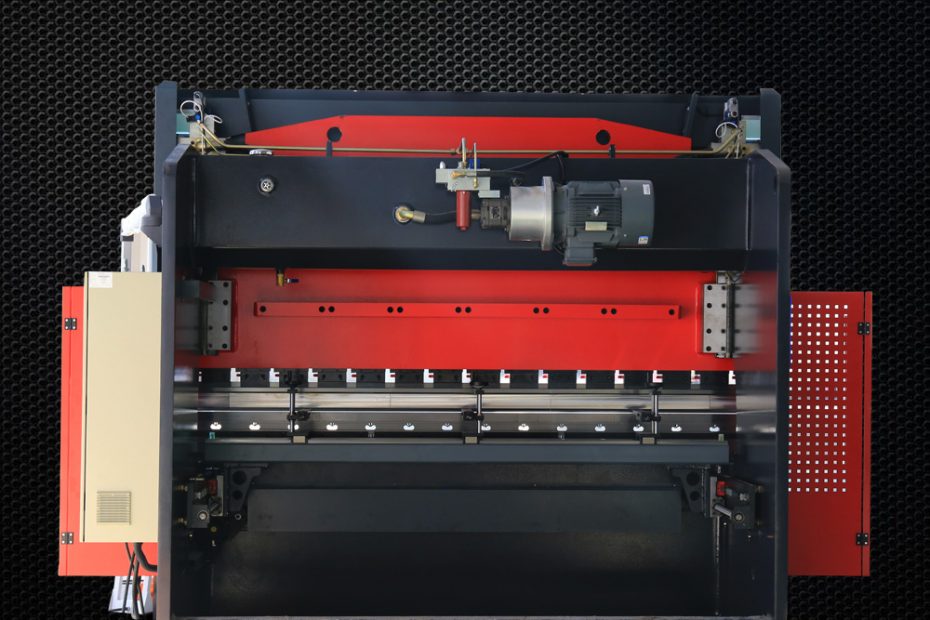

A estrutura e a função da máquina de prensagem hidráulica WC67K-80T 2500

A máquina de prensagem hidráulica WC67K-80T 2500 é a máquina de prensagem hidráulica de aço carbono, aço inoxidável e incluindo aço angular, aço em tiras, aço, fístulas e outros perfis de metais não ferrosos enrolados em anéis e flanges de alta qualidade, instalação de dobragem de alta eficiência. Tem as vantagens de estrutura especial, tamanho pequeno, baixo consumo de energia, alta eficiência, instalação conveniente e uso sem ruído, operação simples, forte energia de suporte de carga, longa vida útil do forno, velocidade de dobra rápida, qualidade confiável de mercadorias e assim por diante. Substitui a chapa de aço original,... Ler mais "A estrutura e a função da máquina de prensagem hidráulica WC67K-80T 2500