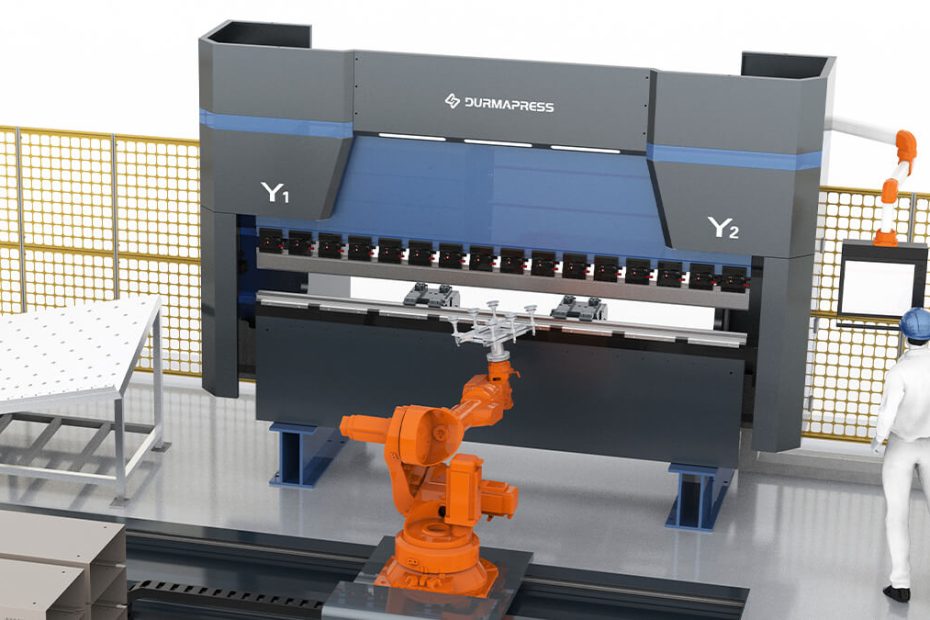

DURMAPRESS Completes Shipments To Brazil And Bhutan

DURMAPRESS continues to promote global business expansion and has recently successfully completed two important shipments, one to Brazil and one to Bhutan. The shipment includes two hydraulic press brakes, a combined punching and shearing machine, a handheld laser welder, and cutting head accessories, demonstrating our competitiveness and industry influence in the global manufacturing equipment market. Shipment details Goods shipped to Brazil The first batch of equipment shipped to Brazil includes two hydraulic press brakes and one combined punching and shearing… Ler mais "DURMAPRESS Completes Shipments To Brazil And Bhutan