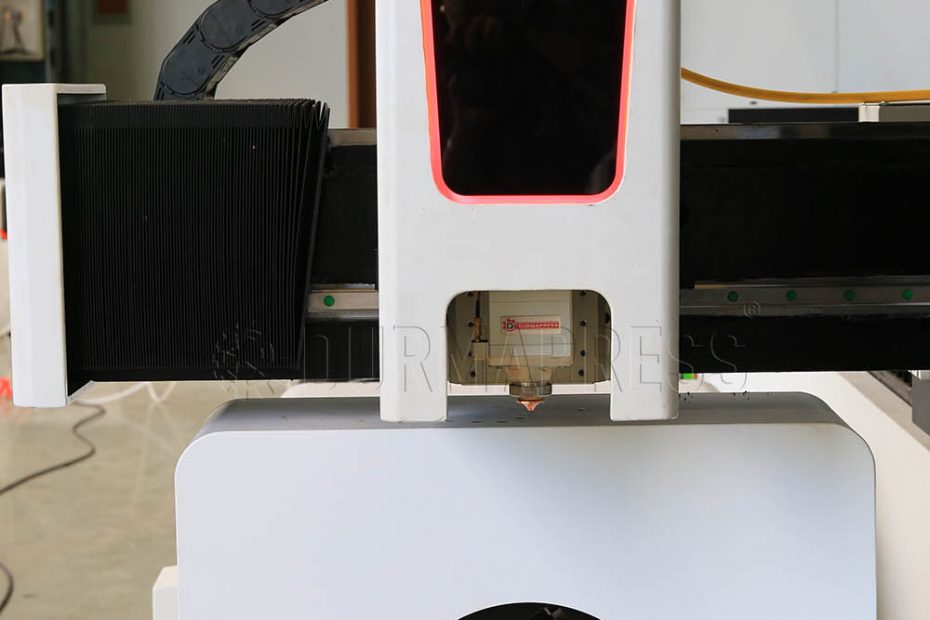

Working principle and component of CO2 laser cutting machine

Working principle and component of CO2 laser cutting machine When it comes to the working principle of CO2 laser cutting machine, we first talk about the composition of CO2 laser cutting machine. Carbon dioxide laser cutting machine is divided into three parts: 1, control part 2, part of the movement 3, part of the light First, the control part consists of control software, central control board and driver, etc. The moving part is composed of guide rail, motor, belt, etc.… Ler mais "Working principle and component of CO2 laser cutting machine