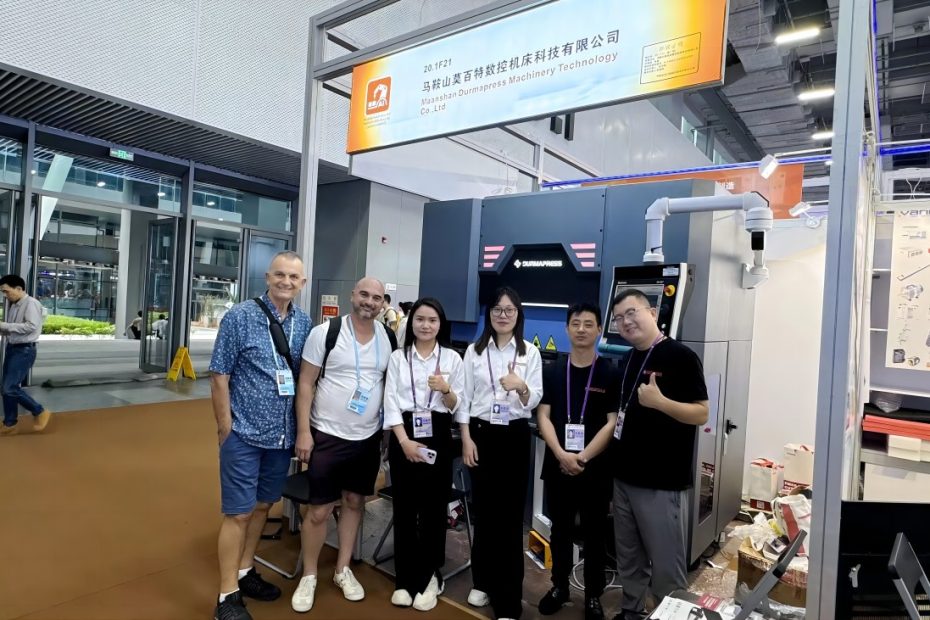

Durmapress Exhibiting at FABTECH Mexico Booth 3029

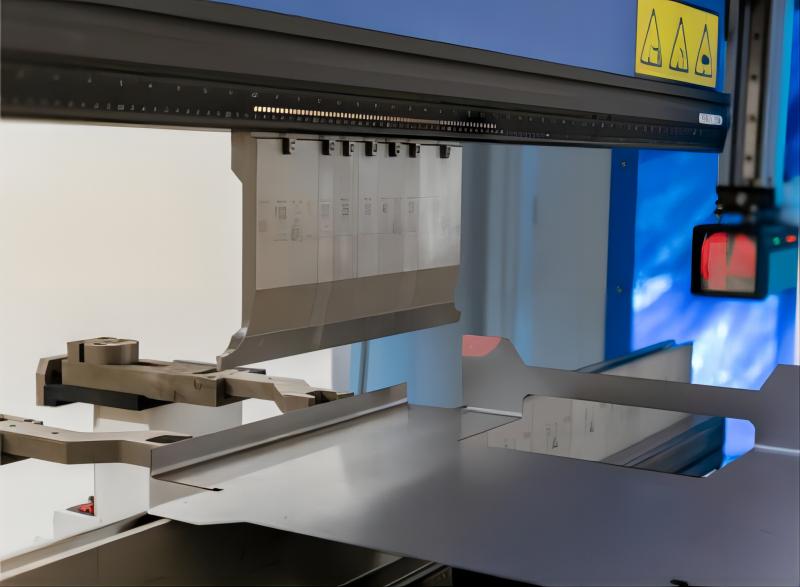

The FABTECH is one of the largest metalworking, welding, and manufacturing technology exhibitions in North America. Durmapress is honored to participate in this event. We will showcase our Durmapress press brake equipped with the DA-63T, which serves as our main promotional product. In addition, our shearing machine, fiber laser cutting machine, rolling machine, among others, will also be featured as our key products.