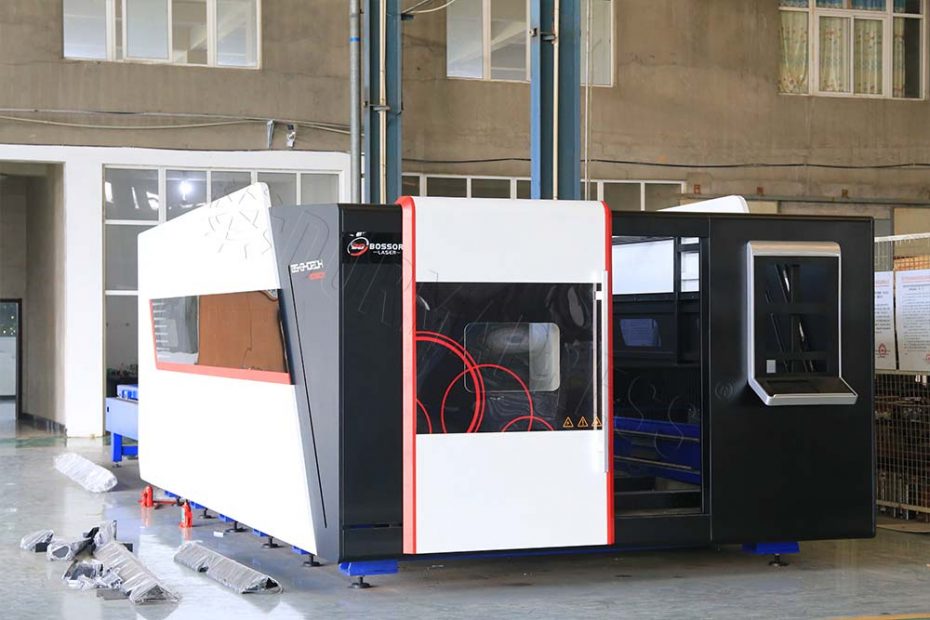

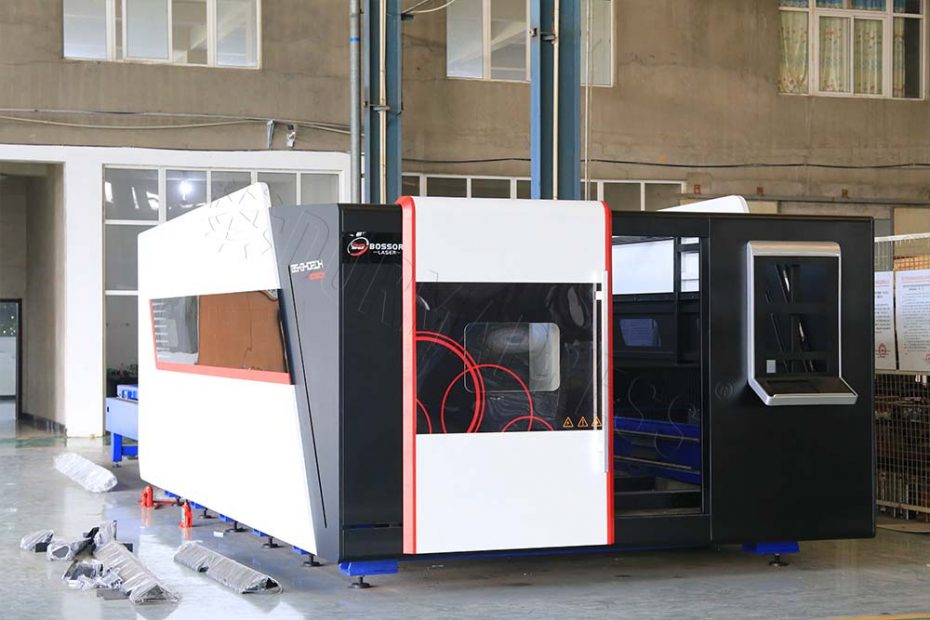

For fiber laser cutting machine 6000w processing, the evaluation of its processing quality mainly includes the following principles

For fiber laser cutting machine 6000w processing, the evaluation of its processing quality mainly includes the following principles: 1. Smooth cutting, no stripes, no brittle fracture; 2. The slit width is narrow, which is mainly related to the size of the laser beam spot diameter; 3. Good verticality of the slit and small heat affected zone; 4. No material combustion, no melting layer formation, no large slag; 5 notch surface roughness, the size of surface roughness is the key to… Ler mais "For fiber laser cutting machine 6000w processing, the evaluation of its processing quality mainly includes the following principles