How to improve the work efficiency of E21 press brake

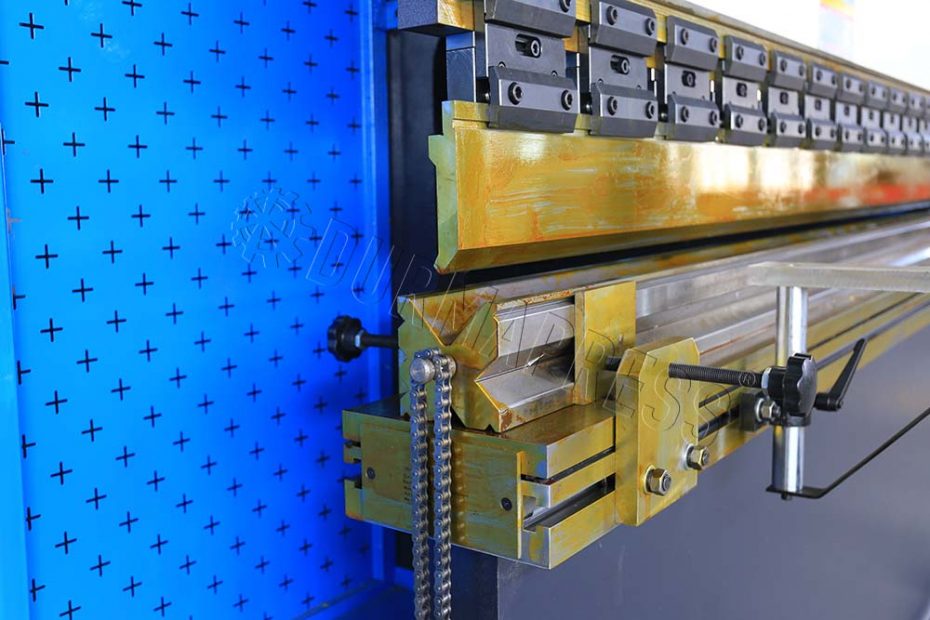

CNC bending machine is a special responsible for the completion of material bending operation of equipment products, users usually in the use of E21 press brake, can first set the parameters, and then send the material into the equipment can quickly complete the processing task. In order to effectively improve the processing speed, the equipment is also set up a lot of programming functions, so that the equipment can complete many kinds of workpiece processing operations at one time when… Ler mais "How to improve the work efficiency of E21 press brake