-300x169.jpg)

Common laser safety devices

Press brakes are equipment with a high risk factor. During the production process, almost every sheet metal factory will have large and small industrial accidents without exception. Especially when bending small workpieces or two people working at the same time, industrial injuries are very likely to occur, such as crushing fingers and arms. So, why do industrial injuries occur during the bending process? There are three main reasons: the operator is negligent and has weak safety awareness; the rhythm of placing the workpiece and stepping on the foot switch is inconsistent; fatigue work and lack of concentration. After the operator is injured, it will seriously affect the quality of life and work in the future; the company needs to pay high compensation; the injured workers take sick leave, delay production, and cause losses to the company. The installation of a special laser safety protection device for the press brake can effectively protect the personal safety of the operator, prevent industrial injuries, prevent hand crushing, and prevent accidents before they happen. The laser safety protection device of the press brake mainly includes: transmitter, receiver, controller, transmission line and mounting bracket, etc. There are four main models: MSD, DSP, DSP AP+MCS and DSP AP EX+MCS EX, as shown in the figure below. Here we mainly introduce the DSP five-point laser safety protection device.

Features of DSP five-point laser safety protection device

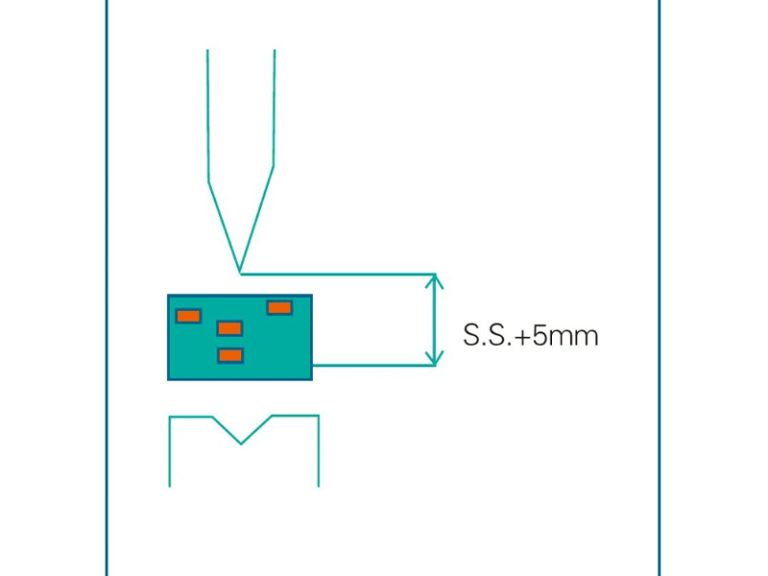

The DSP five-point laser safety protection device complies with CE standards, has a safety level of CAT Ⅳ, and a maximum protection distance of 15m. It is installed on the upper crossbeam or upper slider to form a block-shaped protection area for the bending tip, protecting the front, middle and back areas of the tip. The protection area runs synchronously with the upper mold, which ensures that when the upper slider moves downward at high speed, any object below must enter the protection area generated by DSP before contacting the tip of the knife, thereby preventing the occurrence of work-related injuries. After installing the DSP five-point laser safety protection device, the response time of the press brake is 5ms, and the speed conversion point is 5mm+stop distance. The schematic diagram is shown in the figure below. Additional functions include slow-down shielding function and stop distance detection function (mechanical).

Three modes of DSP five-point laser safety protection device

The DSP five-point laser safety protection device has three modes to choose from, and the schematic diagram of its protection area is shown in the figure below.

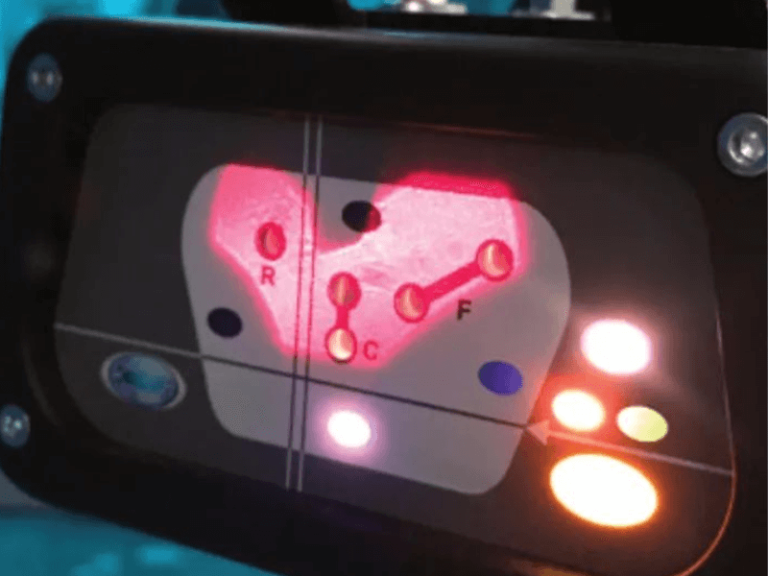

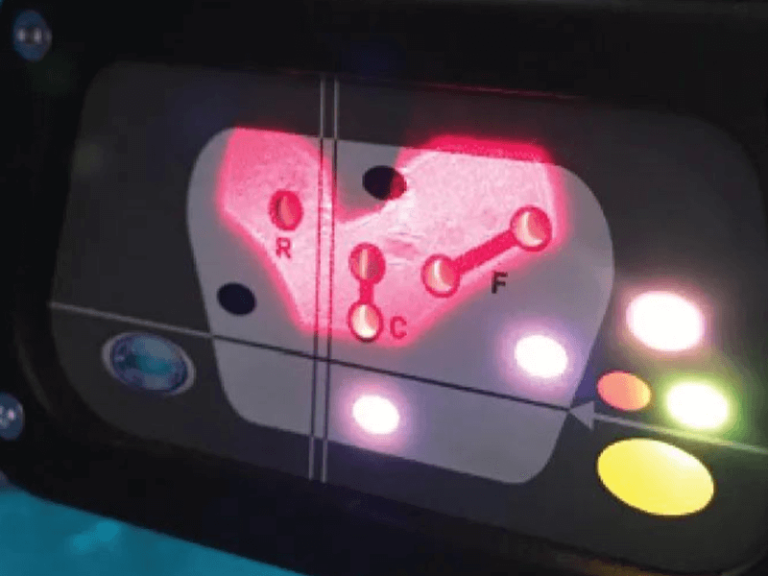

Mode 1: In this operating mode, the laser protection monitoring function of the front, middle and rear areas, a total of 5 points, shown in the figure below, is turned on.

Mode 2: In this operation mode, all diagrams show that only 2 points in the middle area are kept with the laser protection monitoring function turned on, and the protected area is the bending area, as shown in the figure below.

Mode 3: In this operating mode, the monitoring function of 4 points in the front and middle areas shown in all diagrams is turned on, and the protected areas are the operator area and the bending area, as shown in the figure below. This working mode is suitable for the situation where the rear stop finger moves above the mold.

DSP five-point laser safety device mounting bracket

The conventional mounting bracket types of DSP five-point laser safety protection device are shown in the figure below. Different brackets can also be customized according to the mechanical structure and application scenarios of the customer's on-site equipment.

If the press brake is a side plate drawer or the mold is frequently changed during operation, a front and rear sliding bracket can be customized; if the mechanical compensation of the press brake interferes with the motor, the bracket beam can be lengthened, generally to 300-350mm; if the lower beam structure of the press brake is irregular, a transition block and a lengthened beam are required; a reversible bracket can also be used according to actual conditions.

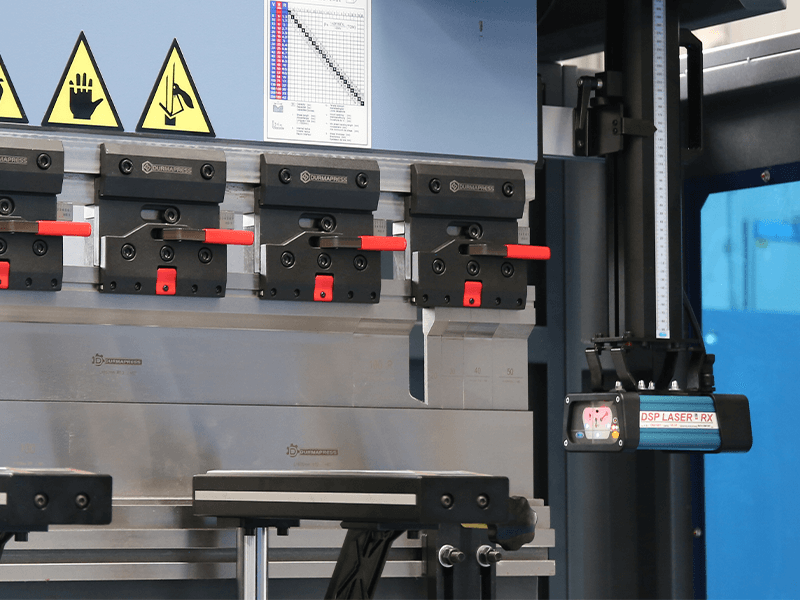

Analysis of the effect of installing DSP five-point laser safety protection device on press brake

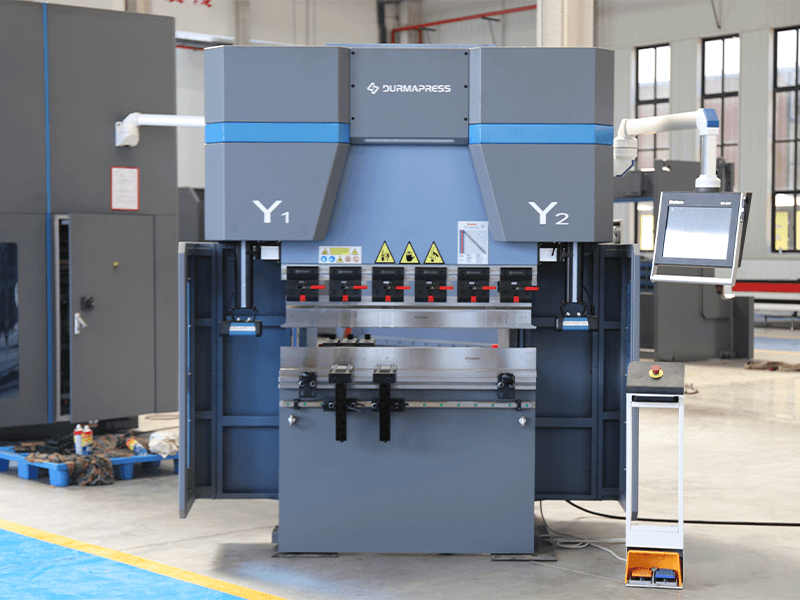

The following is the effect of DURMAPRESS bending machine equipped with laser protection device. If you are interested in our machine, please leave your contact information. If you encounter any problems, DURMAPRESS has professional after-sales personnel to serve you at any time.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)