Máquina de dobrar chapas de 4 rolos

Geral Caraterísticas

1. Precisão, facilidade de operação, dobras de rolo mais rápidas

2. A zona plana dos bordos da folha é reduzida ao mínimo

3. A pré-curvatura, a curvatura cónica e a curvatura em elipse podem ser efectuadas facilmente

4. Pré-dobras duplas (ambas as extremidades) numa só passagem

5. Os sistemas hidráulico e elétrico foram protegidos contra sobrecargas e requerem um mínimo de manutenção

6. Os componentes hidráulicos e eléctricos são modulares e concebidos de acordo com as normas mundiais

7. A folha é controlada pelo aperto dos rolos superior e inferior

8. Operação de quinagem mais adequada para aplicações CNC

9. Mais eficiente em termos de tempos de ciclo

10. Operações fáceis de utilizar sem depender da competência do operador

11. Alimentar a folha de encomenda a preencher pelo prebend Circle, o processo circular mais pequeno

12. Volume na peça de trabalho curva, cilíndrica e cónica

13. Acionamento por transmissão mecânica, transmissão hidráulica para os dois movimentos sob o rolo

2. A zona plana dos bordos da folha é reduzida ao mínimo

3. A pré-curvatura, a curvatura cónica e a curvatura em elipse podem ser efectuadas facilmente

4. Pré-dobras duplas (ambas as extremidades) numa só passagem

5. Os sistemas hidráulico e elétrico foram protegidos contra sobrecargas e requerem um mínimo de manutenção

6. Os componentes hidráulicos e eléctricos são modulares e concebidos de acordo com as normas mundiais

7. A folha é controlada pelo aperto dos rolos superior e inferior

8. Operação de quinagem mais adequada para aplicações CNC

9. Mais eficiente em termos de tempos de ciclo

10. Operações fáceis de utilizar sem depender da competência do operador

11. Alimentar a folha de encomenda a preencher pelo prebend Circle, o processo circular mais pequeno

12. Volume na peça de trabalho curva, cilíndrica e cónica

13. Acionamento por transmissão mecânica, transmissão hidráulica para os dois movimentos sob o rolo

Por que escolher a máquina de laminação BS3015D

►Sistema de guiamento de revestimento, fiável e durável.

►Sistema eletrónico de controlo da sincronização da balança (precisão ± 0,15 mm).

►Rolo de potência dupla com 2 caixas de velocidades e 2 motores hidráulicos.

►Superfície do rolo com tratamento térmico, cuja dureza pode ser HB260-300.

►Sistema hidráulico para evitar sobrecargas.

►Sistema de lubrificação automática.

►Sistema de controlo de baixa tensão.

►Sistema de alarme automático para nível de óleo inferior e filtro entupido.

►Sistema de paragem de segurança, para parar todas as partes móveis de toda a máquina.

Componentes

Equipamento de série:

- Guias lineares para movimento de rolos (RGS)

- 4 rolamentos independentes que suportam os rolos inferiores (MCS)

- Bancos de rolamentos com dupla largura (WHS)

- Sincronização eletrónica do paralelismo dos rolos (EPS)

- Rolos endurecidos e polidos

- Controlo numérico SIEMENS

- Consola de controlo montada no volante

- Dispositivo cónico

- Lubrificação manual centralizada (bomba)

- Barreira de emergência à volta da máquina

- Máquina com certificação CE

Caraterísticas opcionais:

- Rolos laterais motorizados

- Sistemas automáticos de carga e descarga

- Mesa de alimentação motorizada

- Ejetor automático

- Suportes centrais e laterais

- Provisão para laminagem a quente

- Versão com guias planetárias (4HEP)

- Sistema de soldadura integrado

- Cores especiais

Componentes principais

Controlador PLC

- Aeronave de dobragem especial, controlo numérico

- HMI (Interface homem-máquina) Funcionamento inteligente

- Auto-compensação, operação única, alta eficiência, seguro e conveniente

- Muitos modelos de escolha, modelo de controlo numérico económico

, TC Controlo numérico computorizado .

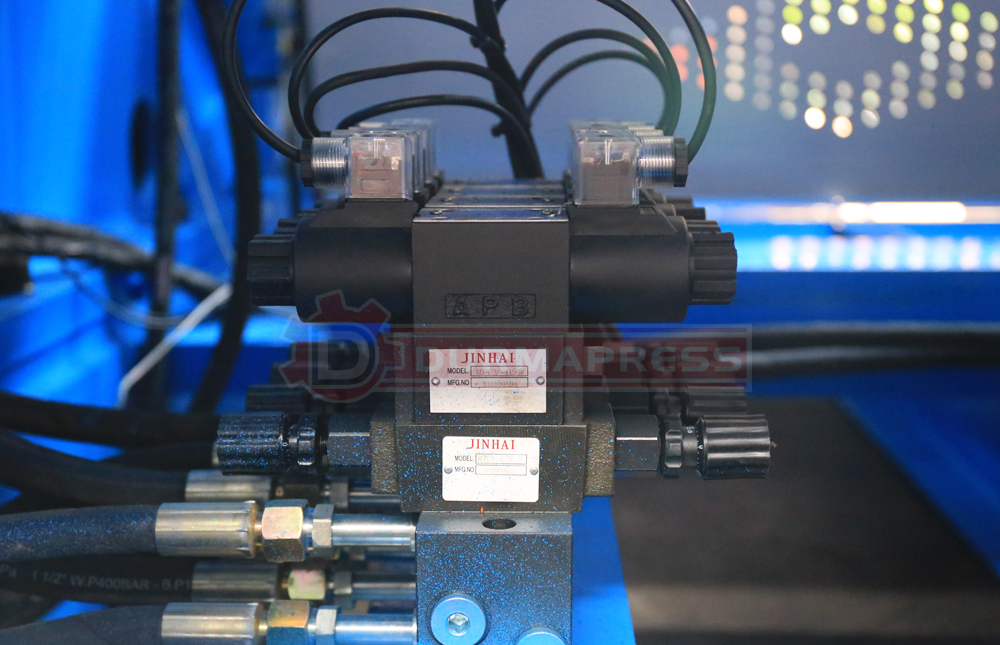

Cilindro de óleo

- Estação de bombagem :ChangYuan,China Opções: Sunny,EUA

- Válvula : Yuken,Japão

Sistema hidráulico

- Através de uma tecnologia exclusiva, pode desenvolver cones tão facilmente como as máquinas concorrentes podem desenvolver cilindros.

Elimina a formação de cicatrizes na superfície da casca ou do rolo e elimina também, na maioria dos casos, a necessidade de retificação da laminação (bullnosing) no bordo de menor diâmetro.

Válvula Yuken fabricada no Japão.

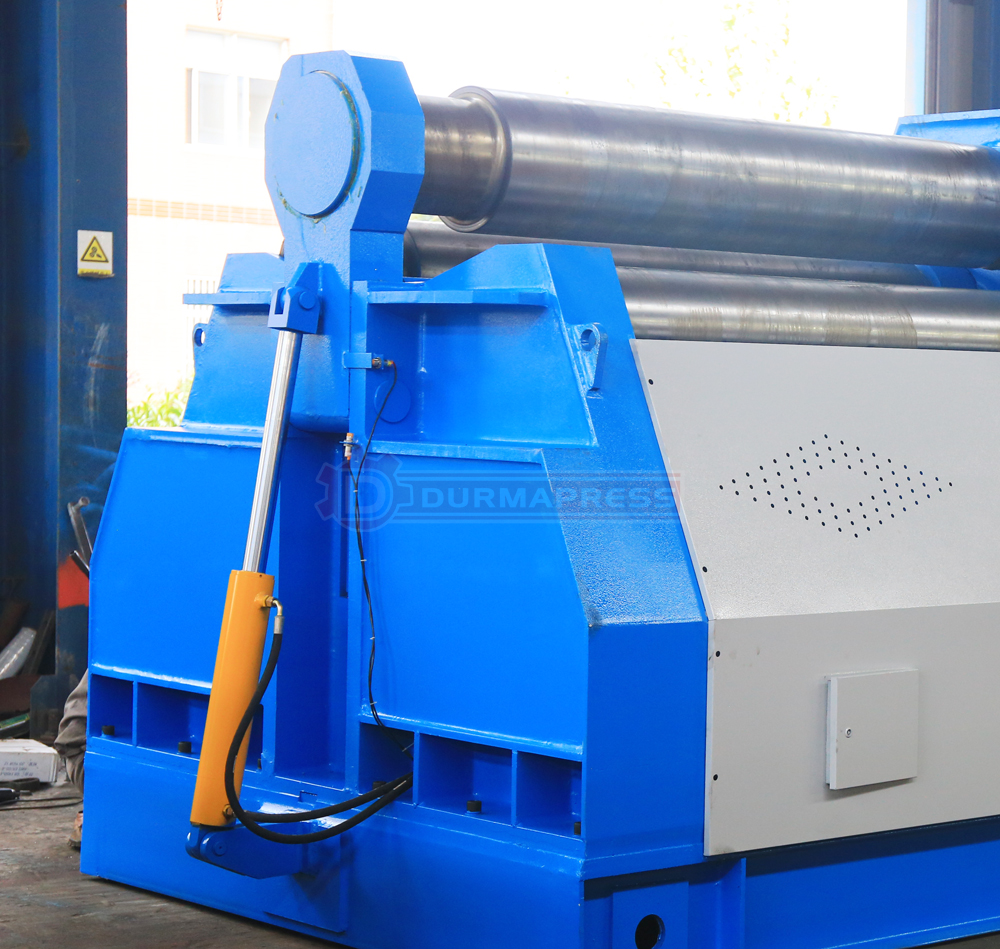

Dispositivo de libertação

Extremidade hidráulica para remoção fácil da virola acabada.

Vídeo de apresentação do produto

Máquina de laminação CNC

Esta máquina é fiável e eficaz. O paralelismo dos rolos laterais é controlado por um sistema de barra de torção que se liga a ambas as extremidades do rolo lateral, eliminando a desvantagem de codificadores adicionais e válvulas de equilíbrio hidráulico especiais. Os dois rolos centrais são acionados por motores hidráulicos e caixas de velocidades planetárias de alta eficiência acopladas diretamente nos rolos. A solução MG, com rolos montados sobre rolamentos vedados e sem componentes secundários, reduz as dispersões da força aplicada geradas pelos atritos dos vários componentes (típicos dos sistemas de sincronização utilizados noutras máquinas de dobragem).

Galeria

Dados técnicos

| Nome | W12-4*3000 | W12-6*2000 | W12-6*2500 | W12-6*3000 | W12-8*2000 | W12-8*2500 | W12-8*3000 | W12-10*2000 | W12-10*2500 | W12-10*3000 | W12-12*2000 | W12-12*2000 | W12-12*3000 | W12-16*2000 | W12-16*2500 | W12-16*3000 | W12-20*2000 | W12-20*2500 | W12-20*3000 | W12-25*2000 | W12-25*2500 | W12-25*3000 | W12-30*2000 | W12-30*2500 | W12-30*3000 | W12-35*2000 | W12-35*2500 | W12-35*3000 | W12-40*2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Espessura máx. Espessura de flexão (mm) | 4 | 8 | 6 | 6 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 | 12 | 16 | 16 | 16 | 20 | 20 | 20 | 25 | 25 | 25 | 30 | 30 | 30 | 35 | 35 | 35 | 40 |

| Espessura de pré-dobragem (mm) | 3 | 5 | 5 | 5 | 6.5 | 6.5 | 6.5 | 8 | 8 | 8 | 8 | 8 | 10 | 13 | 13 | 13 | 16 | 16 | 16 | 20 | 20 | 20 | 25 | 25 | 25 | 28 | 28 | 28 | 32 |

| Comprimento de trabalho do rolo (mm) | 3050 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 3100 | 3100 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2550 |

| Limite de resistência da placa (Mpa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 |

| Diâmetro do rolo superior (mm) | 190 | 190 | 210 | 230 | 210 | 230 | 270 | 230 | 270 | 300 | 300 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 360 | 390 | 430 | 390 | 430 | 460 | 430 | 460 | 510 | 510 |

| Diâmetro do rolo inferior (mm) | 170 | 170 | 190 | 210 | 190 | 210 | 250 | 210 | 250 | 270 | 270 | 270 | 300 | 270 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 360 | 390 | 420 | 390 | 420 | 460 | 460 |

| Diâmetro do rolo lateral (mm) | 150 | 150 | 170 | 0 | 170 | 190 | 210 | 190 | 210 | 220 | 220 | 220 | 240 | 220 | 240 | 250 | 240 | 250 | 300 | 250 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 390 |

| Potência do motor principal (KW) | 4 | 4 | 5.5 | 7.5 | 5.5 | 7.5 | 11 | 7.5 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 15 | 11 | 15 | 18.5 | 15 | 18.5 | 22 | 18.5 | 22 | 30 | 22 | 30 | 30 | 37 |

| Comprimento (mm) | 3650 | 4650 | 5150 | 60 | 4650 | 5250 | 5700 | 4770 | 5270 | 5700 | 5700 | 5700 | 5770 | 4700 | 5550 | 6300 | 4700 | 5800 | 6500 | 5300 | 6250 | 7000 | 5000 | 6500 | 7300 | 6000 | 6800 | 7600 | 7100 |

| Largura (mm) | 1300 | 1300 | 1450 | 1450 | 1420 | 1500 | 2130 | 1420 | 1420 | 1500 | 1500 | 1500 | 1900 | 1500 | 1840 | 2000 | 1900 | 2000 | 2250 | 2000 | 2160 | 2300 | 2160 | 2300 | 2600 | 2300 | 2600 | 2800 | 2800 |

| Altura (mm) | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 2000 | 1400 | 1400 | 1500 | 1500 | 1500 | 1880 | 1500 | 1820 | 2050 | 2000 | 2050 | 2550 | 2050 | 2350 | 2500 | 2350 | 2500 | 2700 | 2500 | 2700 | 2900 | 2900 |

| Peso (KG) | 4800 | 4800 | 5800 | 7000 | 5600 | 6300 | 9500 | 5800 | 6500 | 8800 | 8800 | 8800 | 13500 | 7500 | 12000 | 17000 | 12000 | 15000 | 23000 | 14000 | 22500 | 30000 | 21000 | 27000 | 33000 | 25000 | 31000 | 38500 | 35000 |