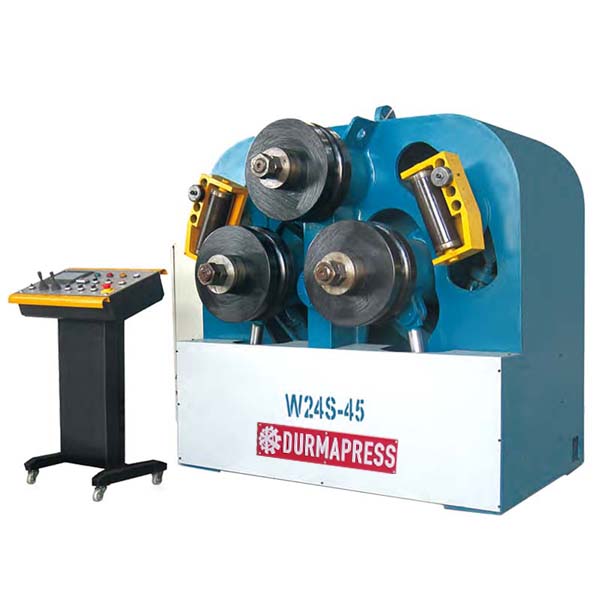

Profile Bending Machine

Profile Bending Machine

General Features

Durmapress Profile Bending Machines are well known for their advanced hydraulic system that guarantees smooth movements, infinitely variable speed and interpolation axis in order to make multi-radii shapes along the same profile. Bending multi-radii shapes is a job where numerical control frequently comes into place. After many decades of developments and experience, Faccin is proud of supplying the highest level of CNC for profile bending machines that feature profile libraries, automatic calculation of the bending cycle, unlimited program storage, automatic interpolation axis, program self correction and many other advanced features.

Working principle of profile bending machines

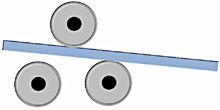

Loading of the part to be bent: in this phase the profile is insert in between the rolls. The part can be supported if necessary and is not subject to deformation stress.

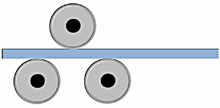

Roll movement in order to achieve the pinching position: during this phase the profile is blocked in between the rolls and can be moved forward and backward rotating the rolls. The pressure exercised is lower than the one necessary to deform the profile.

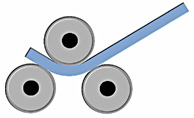

Working phase: in this phase the pressure increases and the deformation of the profile takes place, by translation of the profile and movement of the rolls.

Unloading of the profile: the pressure on the profile is eliminated and is increased the space between the rolls, so that the profile can be extracted from the machine.

Components

Standard equipment:

- Motorised fine adjustment of universal roll height;

- Independent adjustment of the two bending rolls (double pinch);

- Independent side checkers 3D adjustable in 6 directions;

- Simultaneous translation and rotation of the bending rolls;

- Continuously variable rotation speed by interpolation of different radii;

- Automatic compensation of the peripheral roll speed;

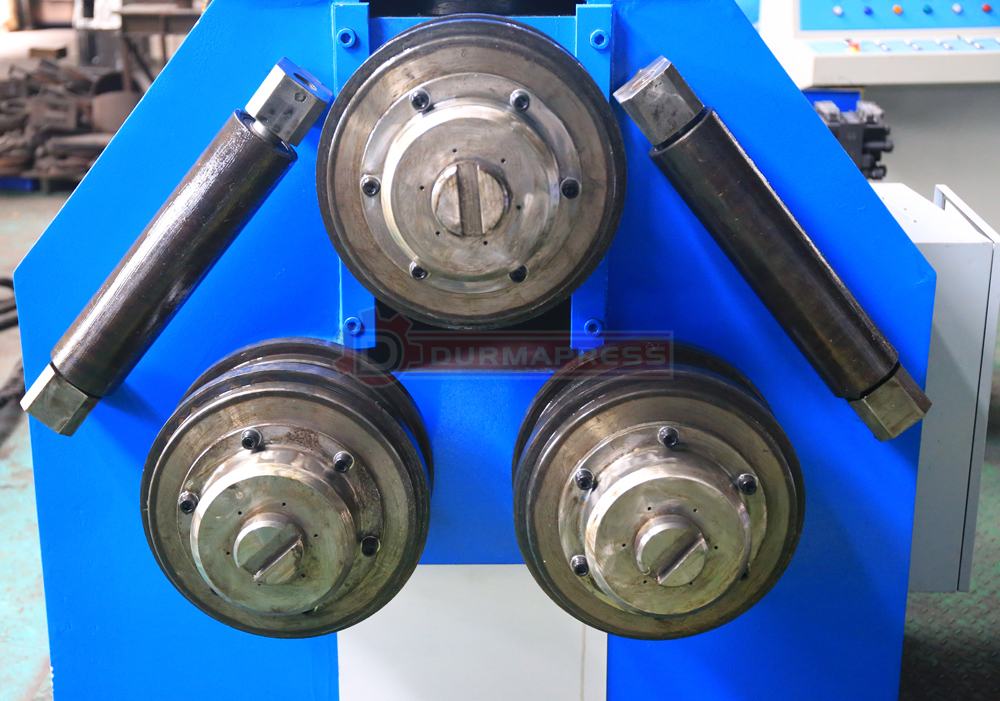

- 3 independently driven shafts with expandable couple;

- 3 hydraulic motors and 3 planetary gear boxes for roll rotation;

- Special, very high strength forged steel used for the rolls;

- Ni Cr Mo forged and hardened steel roll-holder shafts;

- Optionally, mobile wheel mounted console or pendant console;

- CE certified machine.

Optional features:

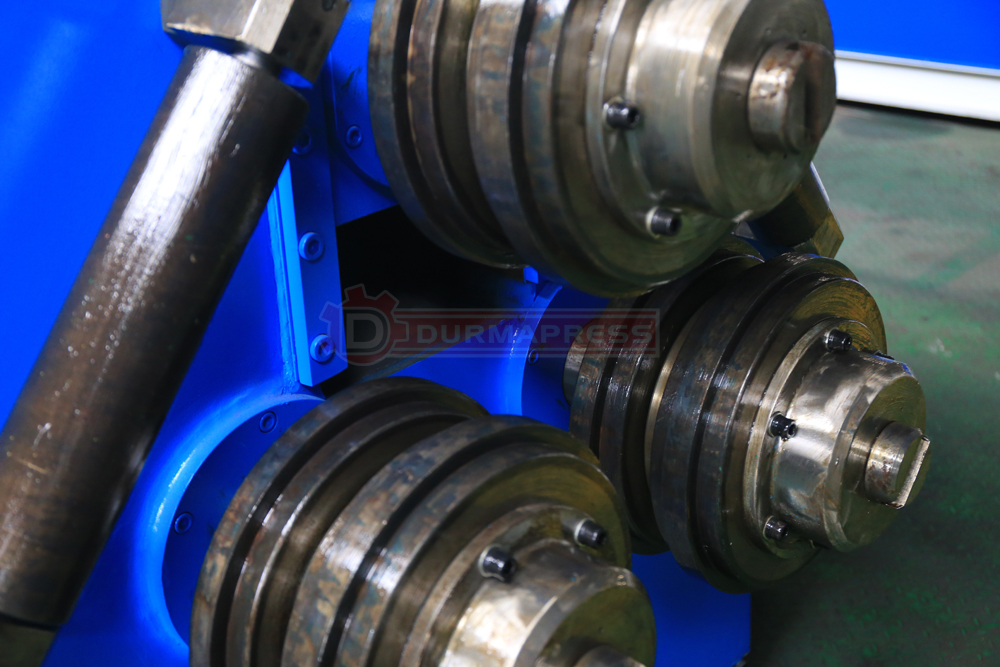

- Set of rolls for bending all standard profiles;

- Alternatively, Set of Universal rolls for bending all standard profiles and H, I, and U beams;

- Pipes and RHS rolls;

- Hydraulic guides for bending profiles in hard-way directions;

Main Components

Machine Body Welding

- Steel welded construction frame.

- Hardened shafts from special steel material.

- Top roll hydraulic movable up-down.

- Horizontal and vertical working position optional.

- Mobile control panel.

Control System

- Mobile control panel.

- The operation table is set with indicators foreach part's movement.

- lt also can be controlled remotely, being ofthe high automatic level, convenient opera-tion, safety and low failure rate.

Hydraulic System

- Through exclusive technology, it can developcones as easily as competitive machines can de-velop cylinders.

lt eliminates scarring on the surface of shell or rolland also eliminates, in most cases, the need forgrinding the lamination (bullnosing) on the minordiameter edge.

Yuken valve made in Japan.

Roller

- Two bottom rollers fixed, top roller lifting by hydraulic oil tank.

- Three drive rolls

Product Introduction Video

Profile Bending Machine Working

A profile bending machine is a machine used to perform cold bending on profiles with different shape and size. Usually the machine is used in the metalworking field to bend profiles like tubes, bars, angles, “T” profiles, “U” profiles and beams.

The most important part of the machine are the rolls (normally 3) that apply a combination of forces on the profile, the resultant of which determinates a deformation, along a direction perpendicular to the axis of the profile itself

Technical Data

| Technical Parameter | W24S-6 | W24S-16 | W24S-30 | W24S-45 | W24S-75 | W24S-100 | W24S-140 | W24S-180 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Max. Bending Section Modulus | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | ||

| Rolling Speed(m/min) | 6 | 6 | 5 | 5 | 5 | 5 | 4 | 4 | ||

| Yield Strength (Mpa) | S=450 | S=450 | S=450 | S=450 | S=450 | S=450 | S=450 | S=450 | ||

| Angle Inside Bending | Max. Bending Size(mm) | 40X5 | 70X8 | 80X8 | 90x10 | 100X10 | 120X12 | 140X16 | 150X16 | |

| Angle Outside Bending | Max. Bending Size(mm) | 50X5 | 80X8 | 90X10 | 100x10 | 120X12 | 140X16 | 150X16 | 160X16 | |

| U-steel Outside | Max. Bending Size(mm) | 8 | 12 | 16 | 20 | 25 | 28 | 30 | 32 | |

| U-steel V-Inside Bending | Max. Bending Size(mm) | 8 | 12 | 16 | 20 | 25 | 28 | 30 | 32 | |

| Flat Horizontal Bending | Max. Bending Size(mm) | 100X18 | 150X25 | 180X25 | 200x30 | 220X40 | 250X40 | 280X50 | 300X50 | |

| Flat Vertical Bending | Max. Bending Size(mm) | 50X12 | 75X16 | 90X20 | 100x25 | 110X40 | 120X40 | 150X40 | 180X30 | |

| Round Pipe | Max. Bending Size(mm) | 42X4 | 76X4.5 | 89X5 | 89x8 | 114X5 | 159X5 | 186X6 | 168X8 | |

| Round Steel | Max. Bending Size(mm) | 38 | 52 | 62 | 75 | 85 | 90 | 100 | 110 | |

| Square | Max. Bending Size(mm) | 45X3 | 60X4 | 70X4 | 80x6 | 90X8 | 100X10 | 125X10 | 140X10 | |