Application Of Robots In Bending

The common application areas of industrial robots are mainly concentrated in welding, spraying, and handling. Is it useful in the field of bending? Of course it is useful. 40% to

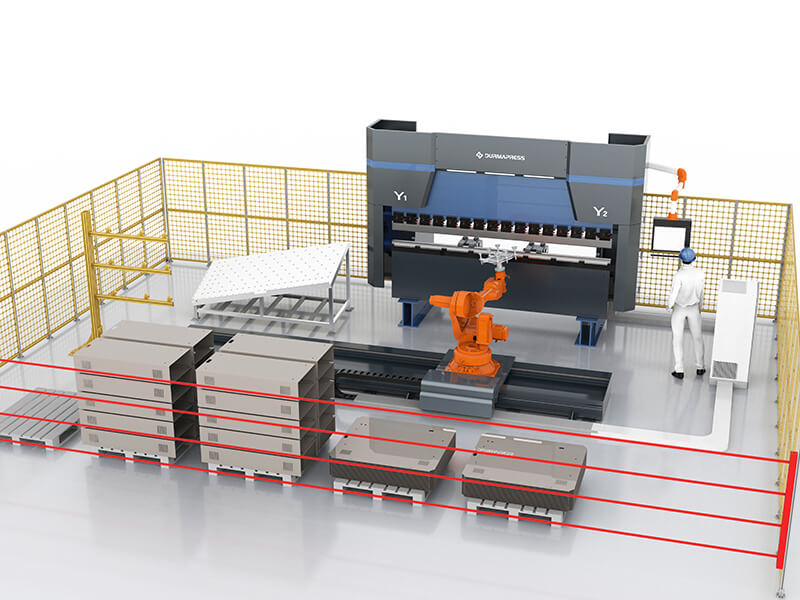

Solution / Press Brake Robotic Cell

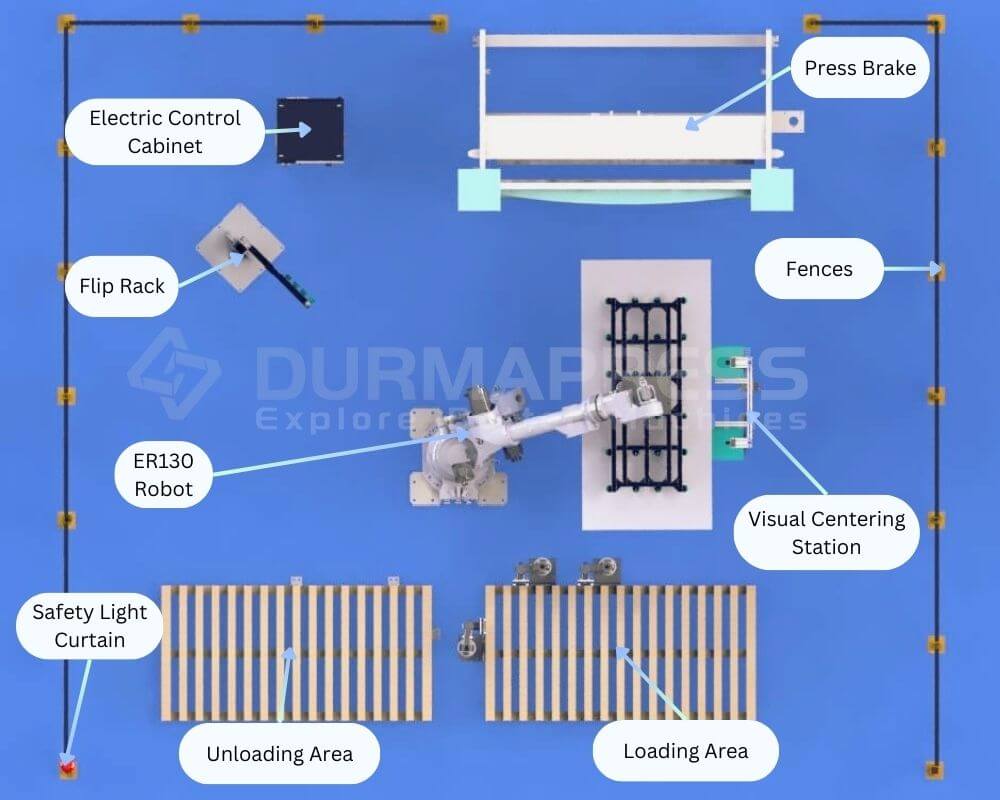

DURMAPRESS Robotic Press Brake represents our commitment to pioneering cutting-edge bending solutions. Paired with automatic loading and unloading systems, our robotic press brake delivers two levels of automation—process and operation—ensuring unparalleled efficiency and precision.

Designed for unattended operation, even during nighttime, our solution drastically reduces setup time, ensures accurate bend angles, and produces high-quality finished parts. With all risks related to part handling during bending managed by the robot, operators are free from any concerns, allowing for a safer and more productive workflow.

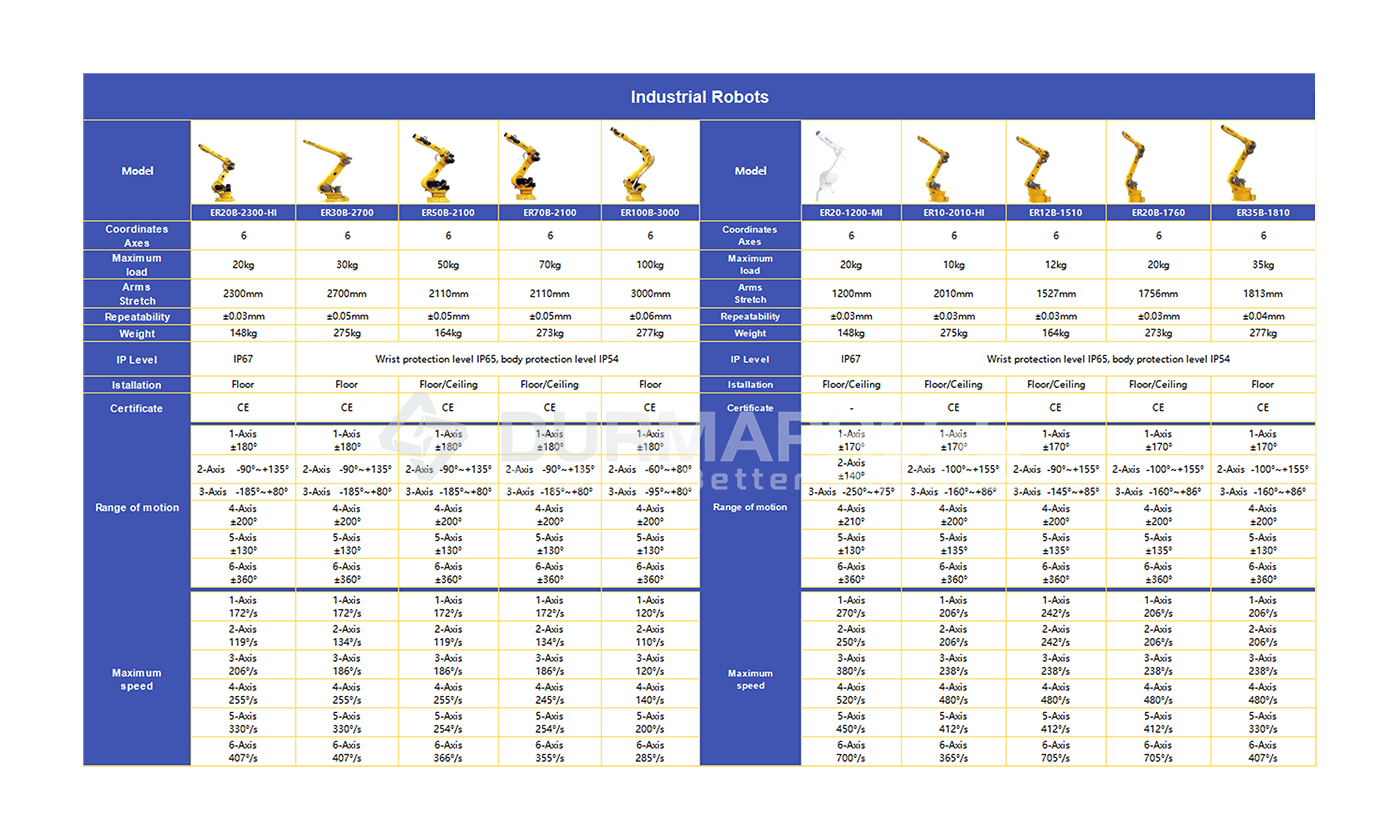

The company has a full range of industrial robot products, including six-axis general-purpose robots, four-axis palletizing robots, SCARA robots and other series. The specifications of standard industrial robots range from 3kg to 700kg, basically covering all areas of industrial robot applications.

The developed visual alignment and offline programming systems can greatly improve the intelligence of sheet metal production and reduce the difficulty of production line operation. In addition, the intelligent manufacturing system established by machine tools, robots and the Internet has been realized, connected to the MES system, and the production line can be remotely controlled and the status of the production line can be viewed in real time.

Precision, efficiency, and durability with Industry 4.0 integration

With advanced control systems and high-quality components, they deliver consistent and accurate bends, ensuring your parts meet the highest standards of quality.

Our Robotic Cell leverage Industry 4.0 connectivity, enabling seamless integration with other machines and systems in the production line. With real-time monitoring, predictive maintenance.

Built for long-lasting performance, they are optimized for smart factory ecosystems, where they can continuously adapt to evolving requirements while maintaining superior durability and reliability.

The robot system is mainly composed of three parts: robot body, control cabinet, and teaching pendant.

Precision, efficiency, and durability with Industry 4.0 integration

Send us your press brake model and tooling details, and receive a tailored clamping system solution within 24 hours.

The common application areas of industrial robots are mainly concentrated in welding, spraying, and handling. Is it useful in the field of bending? Of course it is useful. 40% to

With the rapid development of sheet metal production towards automation and intelligence, the application of robot bending units and panel benders is becoming more and more popular. So how do

Analysis of the current status of bending technology in sheet metal industry At present, intelligent and flexible processing technology has become the pursuit and desire of high-end sheet metal manufacturers.

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!