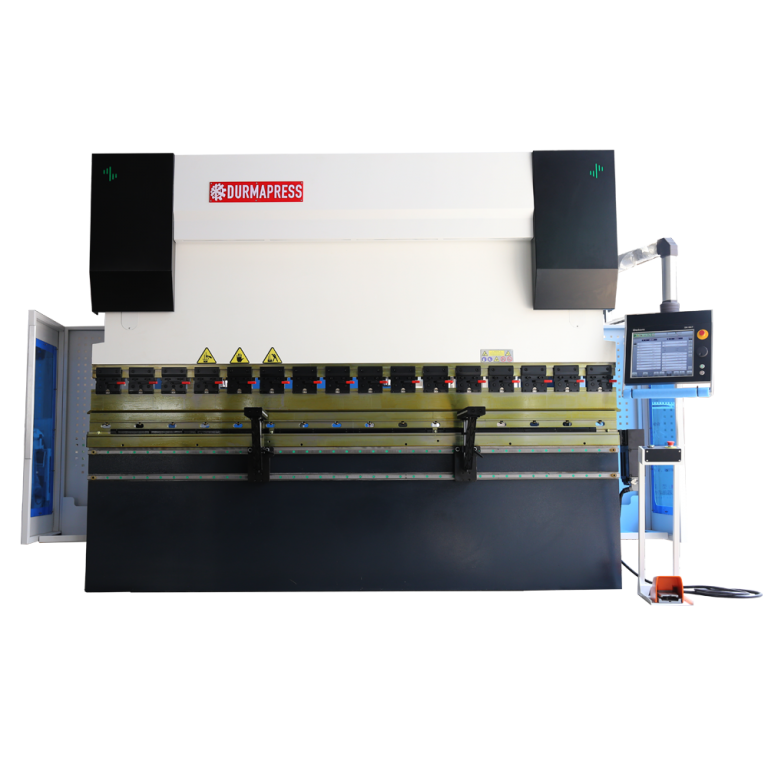

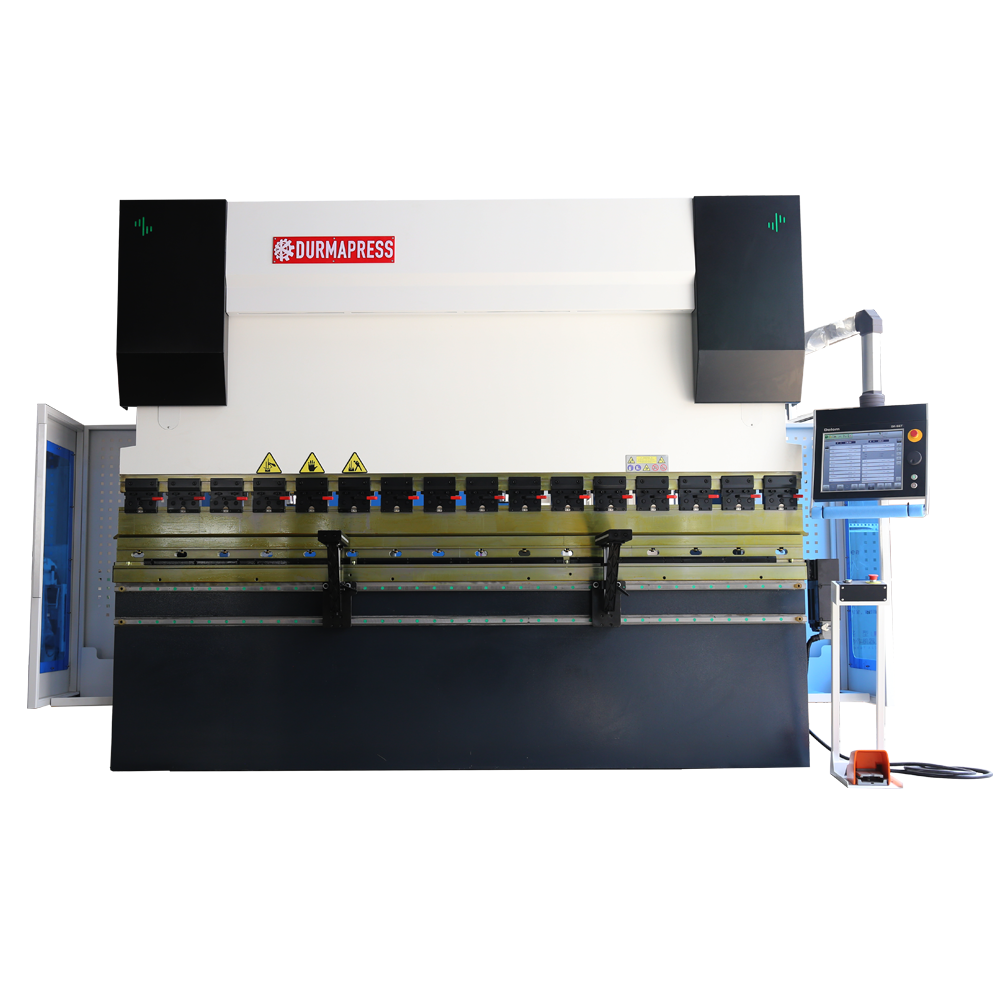

Press Brake Machine can widely used in steel sheet metal processing industry . Mostly we can used in the following industry as below :

Decorating Industry

CNC Press Brakes can be used for the production of stainless steel sheets, doors and windows, as well as for the decoration of special places.

Electrical Industry

The Steel plates can be cutted into different required sizes by shearing machines and then re-processed by Hydraulic Press Brake Machine, such as computer cases, electrical cabinets, refrigerator and air conditioning housings, etc which are all made in this way.

Kitchen Restaurants Industry

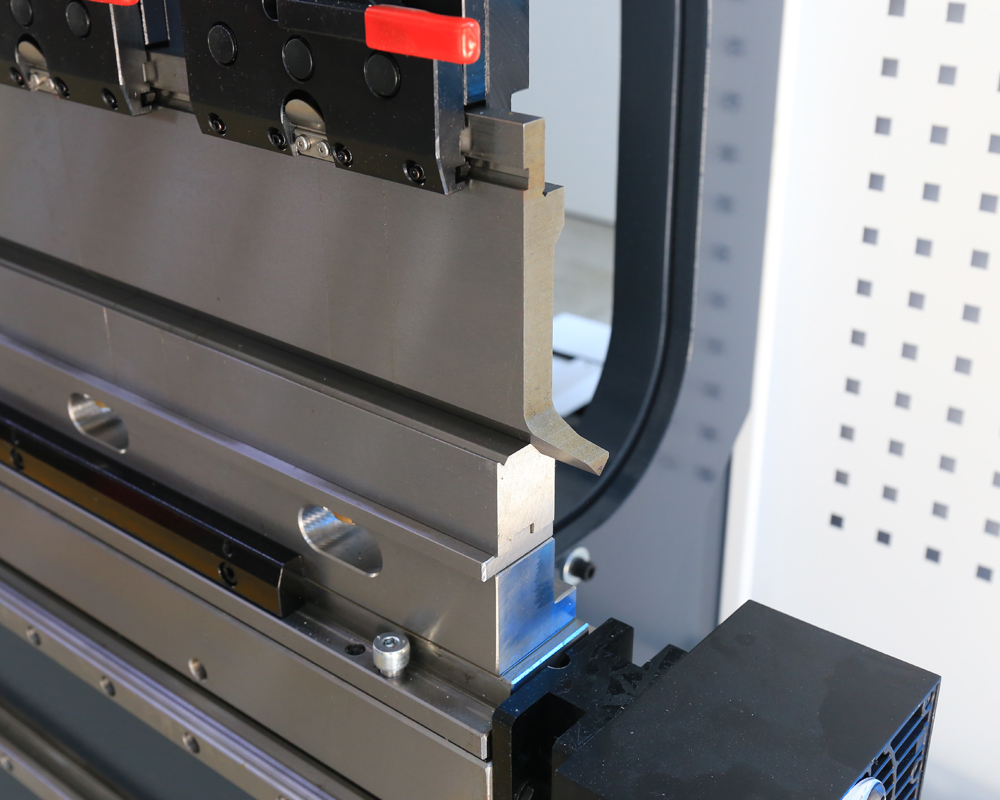

Various varieties and specifications of Stainless Steel kitchenware are bending to different angles and shapes by the Hydraulic CNC Press Brake , then in secondary processing, such as welding and etc.

Wind Communication Industry

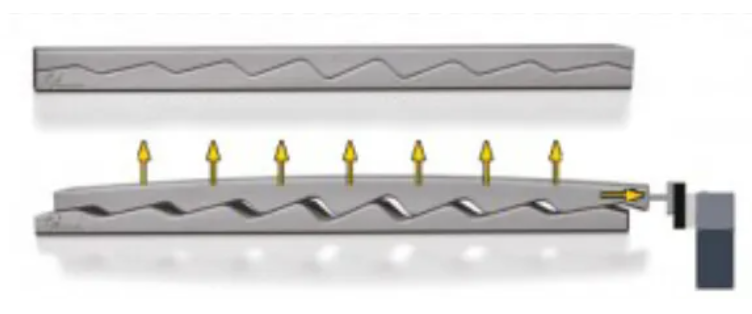

Press Brake can bend the wind power poles, light poles on the road, communication tower poles, traffic light poles, traffic signal poles, monitoring poles, etc. It usually need the heavy duty Press Brake , 6meters and 8meters Tandem Press Brake to finished such products .

Automotive & Marine Industry

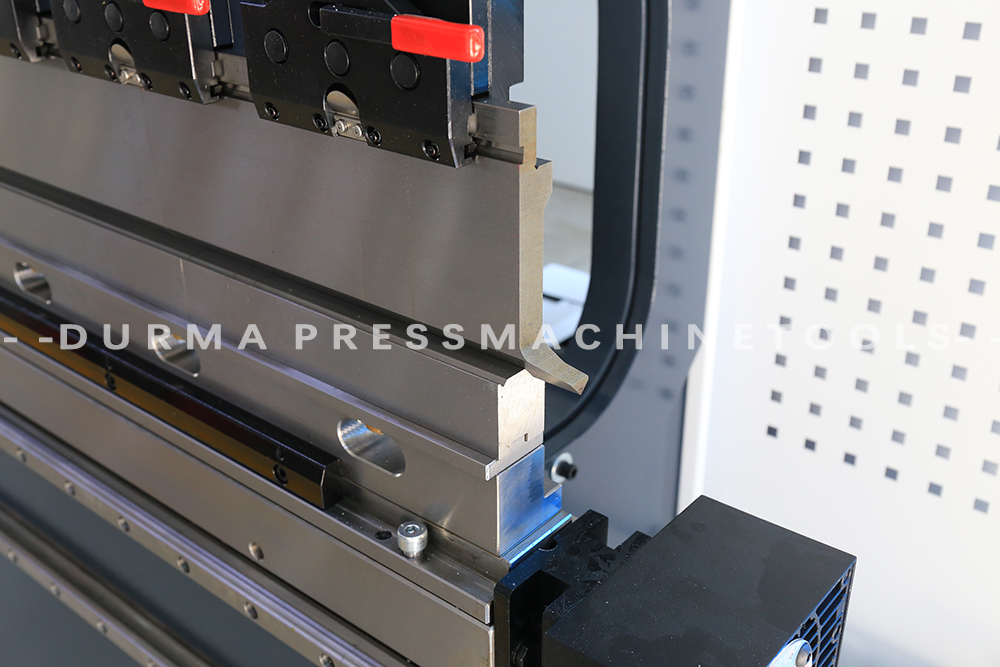

Large CNC hydraulic press brake are used to bending body of boat, It also need combined the heavy duty hydraulic guillotine shearing machine .Bending Upper Punch and Down die should be customized according to Boat body drawings .

Aerospace Industry

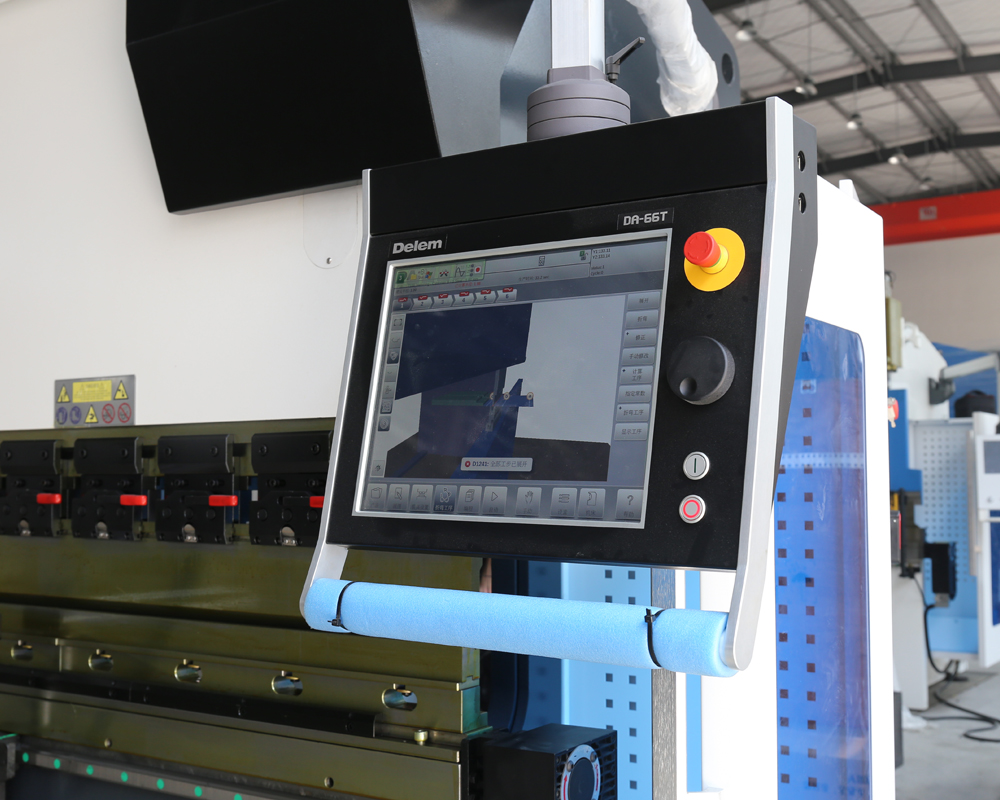

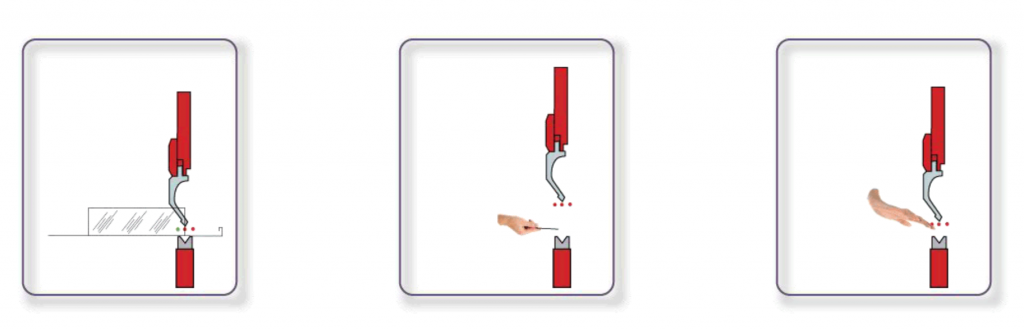

Arospace industry should use high precision CNC Press Brake machine, accurate and efficient. Because The final products is the main parts which must be in the tolerence accepted ranged .

Conclusion :

From non-ferrous metals, ferrous metal plates, automotive ships, electrical power, decoration, kitchen plates, chassis cabinets, lift cabinet door shear, bending processing; large to the aerospace field, CNC Press Brake Machine's role importance are increasingly . In short, the development of CNC Press Brake is very promising,The development prospects of CNC Press Brake will have a very broad space .