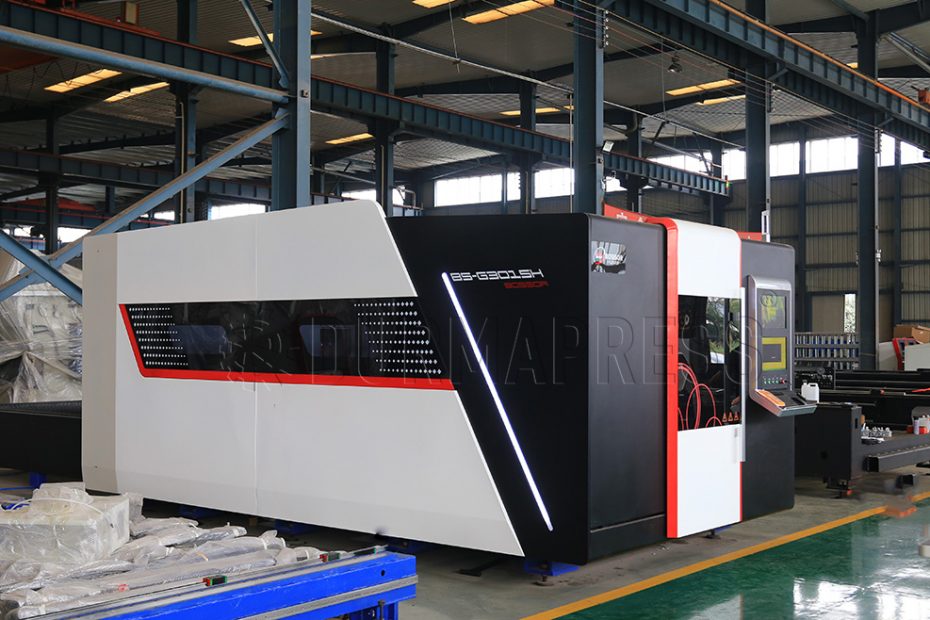

After optical 1500W fiber laser cutting is shut down for a long time, in order to ensure an fully reliable operation of the equipment, extend the service time, and avoid unnecessary trouble caused by irregular startup for future use, the following steps should be followed before startup.

1. Start the main power supply and the voltage regulator power supply (before starting the power supply, check whether all lines are damaged or have poor contact)

2. Switch on the main power switch (NO)

3. After filling the chiller with water, start the power switch (the water level should be above the green area) to check the water temperature (25℃ for low temperature and 28℃ for high temperature water), the water pressure is normal, and the water pipe joint is leaking.

4. Start the laser power switch (wait until the high and low temperature of the chiller is stable at the set value before starting)

5. Turn on the nitrogen, oxygen, and main valve to check whether the output pressure is normal and whether there is air leakage. (In addition to the air compressor, start the main power supply of the air compressor and the cold and dry power supply)

6. Start the laser cutting software, manually operate the X/Y/Z axis motion is normal, click back to the origin, check the ceramic ring, nozzle is tight, open the BCS100 for servo calibration, floating head calibration, automatic adjustment.

7. Check whether the protective lens is contaminated and make sure the coaxial is in the nozzle.

8. Press manual air blowing to confirm whether the gas pressure is normal.

9. Get the process parameters and cutting drawings to ensure the correct processing parameters.

10. Press the frame button to ensure that the red light is within the range of the plate.

11. Start processing, the machine must be monitored by the operator when running.