features

- Fast speed, only 0.2 seconds per cut.

- Fast workpiece formation and high consistency.

- Simple and low cost routine maintenance.

- Wide range of applicable materials, mainly stainless steel, cold-rolled sheets, etc.

- 3 to 4 times more efficient than manual bending machines.

- The control system realises 9-axis concurrent linkage in the true sense, with smooth bending movements and high mechanical synergy.

- Can automatically bend arcs, dead edges, and various angles.

- Features a highly intelligent control system for efficient bending.

- Saves energy, reduces labor and mold costs.

Exporting country

0

+

Customer satisfaction Rate

0

/5

Professional team members

0

Standard Component

Main Component

Cast Iron Frame

The frame offers stability, durability, and support for its various components. Its design allows for versatility, enabling the machine to perform multiple functions.

Control System

The control system enables true 9-axis concurrent linkage for smooth bending and high synergy. Off-load and plate thickness detection systems protect the machine and reduce workpiece waste.

Servo manipulator

FuI closed-loop servo control system, to realize the workpiece rotation at any angle, feeding, and rotation linkage, reduce the workpiece rotation, feeding and positioning time production improve efficiency.

Auxiliary Blades Option

The auxiliary blades are used for partial bending in which the bending line is broken or offset bending in which the bending line is not at the same line as the main bending line.

workbench

The workbench is made of high-strength material and its surface is specially treated to prevent the metal plate from being scratched or sliding during processing, ensuring the smooth processing and protecting the surface quality of the workpiece.

motor

A servo motor with a high precision helical planetary reducer and heavy-duty grinding screw drives the bending tool along a programmed path, ensuring a stable, efficient structure and easy maintenance.

heat dissipation system

The heat dissipation system prevents the device from overheating due to long-term operation. It also has dust-proof and waterproof functions to ensure that the device can still operate stably in complex environments.

electrical carbinet

The electrical cabinet integrates the electrical control system of the machine, including important components such as frequency converter, PLC controller, switching power supply, etc., making the equipment operation more centralized and convenient.

Get a quote now!

Get more details about DURMAPRESS®’s Top level DP-Hybrid Servo press brake

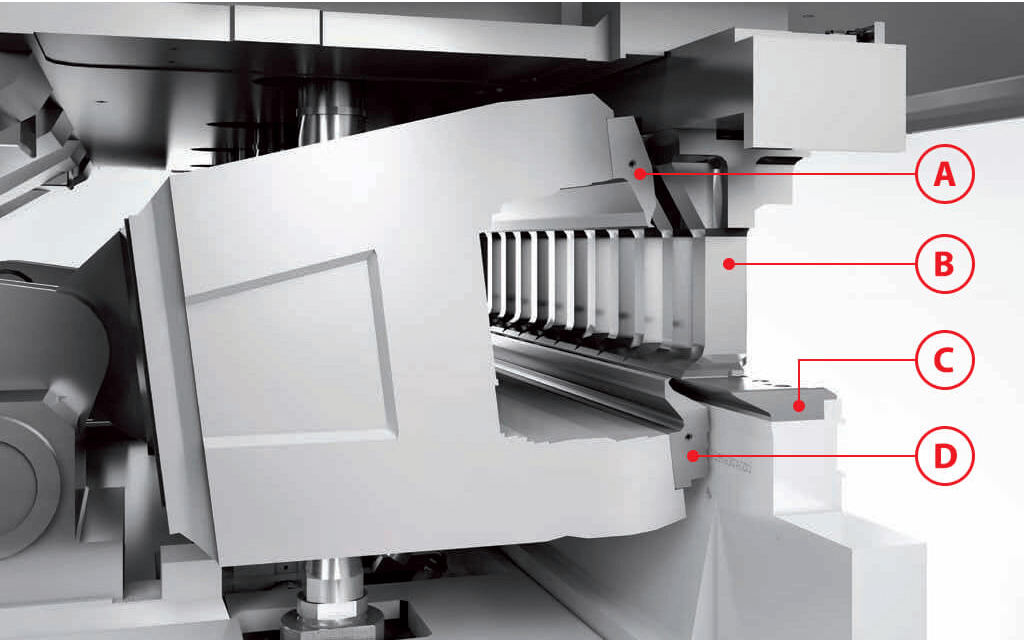

Flexible Tools

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 3.2 mm. The materials are processed during the cycle and without machine down times or manual re-tooling.

- The upper and lower blades (A, D) are the two tools featuring interpolated controlled movement and responsible for bending.

- The ABA blankholder (B) bends and clamps sheets, adjusting to part sizes without downtime, enabling bends up to 45 mm inward.

- The counterblade (C) helps clamp the sheet during the cycle.

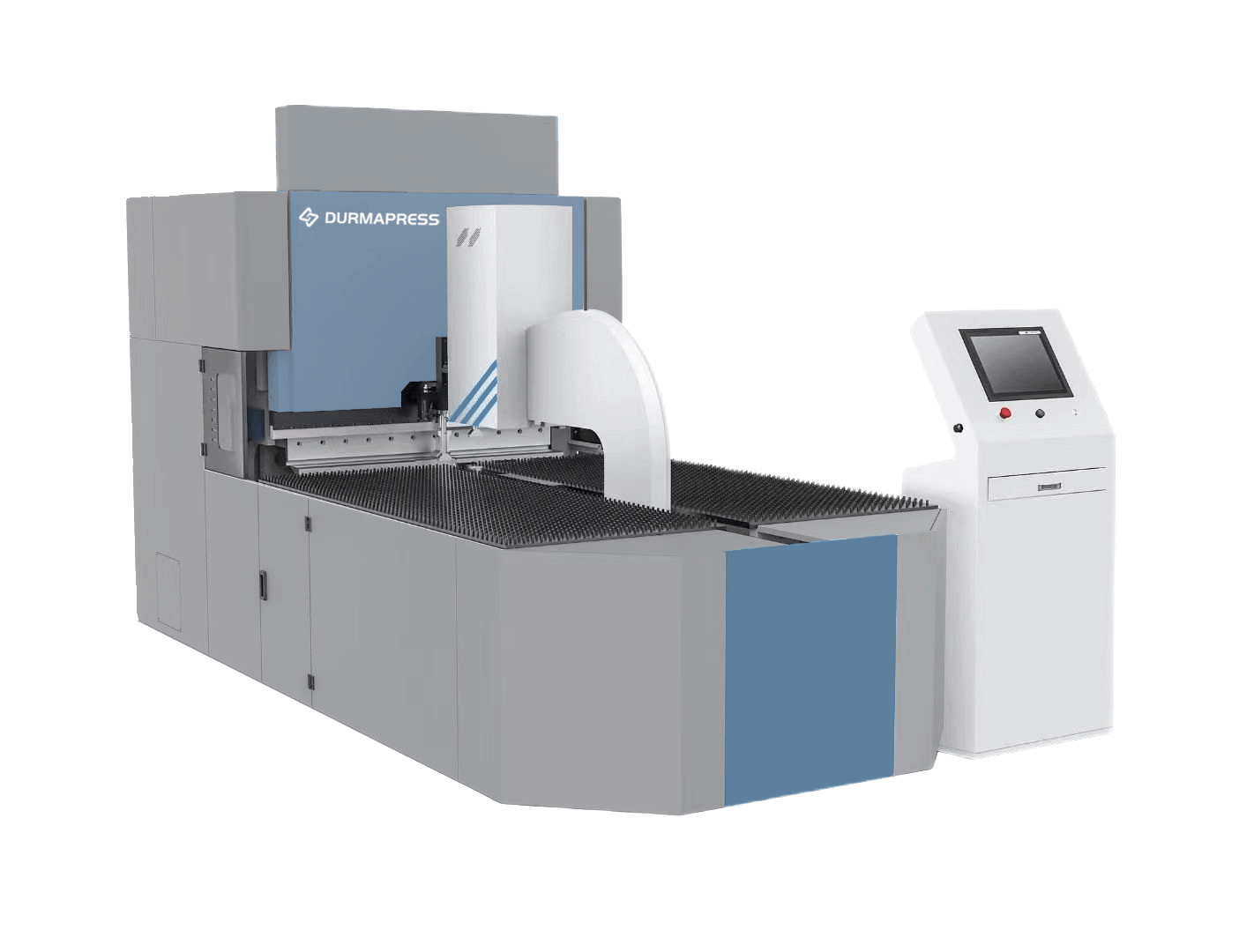

PBE series

Why choose panel bender?

1

Energy Saving

Output according to actual tonnage, start when the motor is running, saving energy and electricity bills.

2

Environmentally Friendly

The oil volume is small and there is no need to change the oil later. It is environmentally friendly, saves costs and has low noise.

3

Increased Efficiency

Achieving a 30% efficiency increase significantly boosts productivity, leading to cost savings and improved profitability.

4

High Precision Performance

High precision in the Hybrid Electric Double Servo Pumps Control Hydraulic System ensures accurate bending and shaping of materials, resulting in precise finished products.

5

Durable Machine Body

The actual tonnage output makes the machine body more durable and does not damage the tool mold.

6

Stable Operation

The servo pump control motor has good software and hardware compatibility, the system is stable, and the machine does not stop all day long.

durmapree factory

Watch the Video

Manufacturer of cutting-edge metal processing equipment

durmapree factory

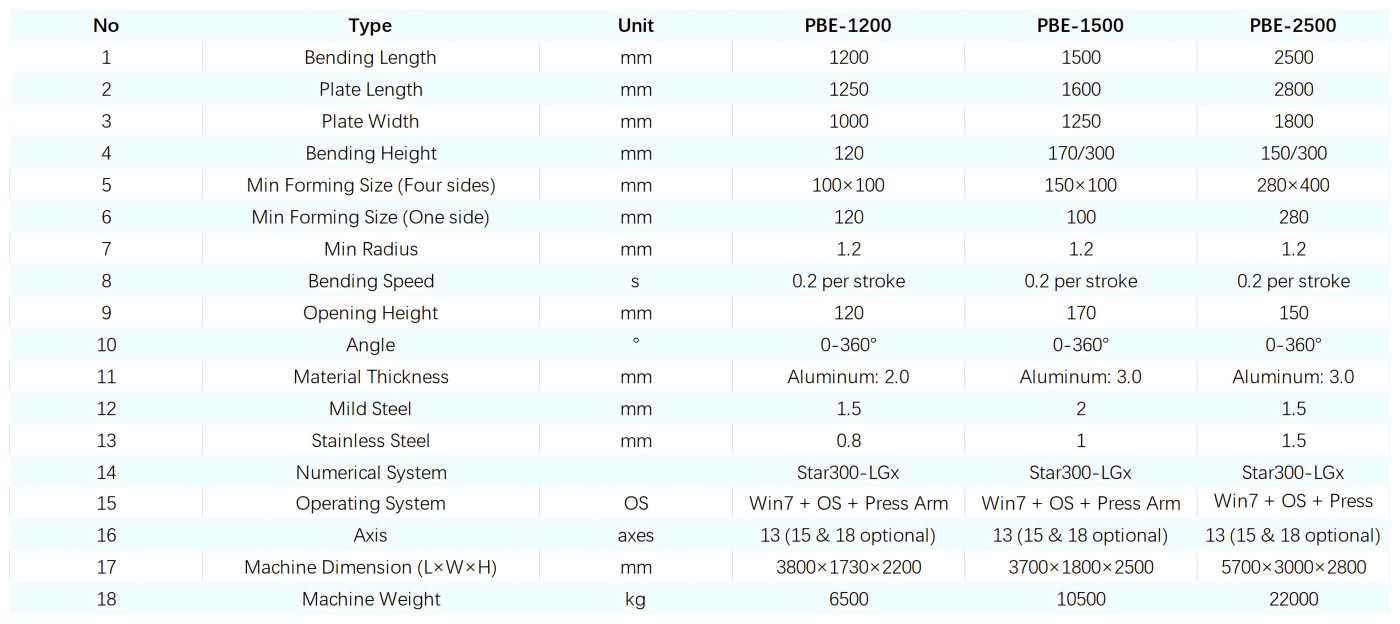

Product parameters

Technical Data

Main Components

Technical Data

Main Components

durmapree factory

Processing Equipment

Manufacturer of cutting-edge metal processing equipment

Contact us

Location

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Our Hours

7/24

Follow Us