Operating an NC plasma cutting machine effectively requires careful setup and precise adjustment of cutting parameters. These machines are designed to cut various metals like steel and aluminum with high precision by using electrically conductive gas. Begin by securely connecting the power and gas supplies, ensuring the plasma gas is properly connected and the pressure settings match the material. Position the metal sheet on the cutting bed, making sure it’s flat and securely clamped.

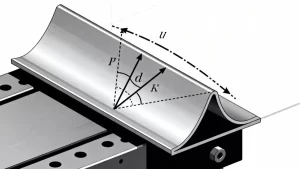

Key cutting parameters include cutting speed, amperage, torch height, and gas flow rate. Adjust the cutting speed according to the material’s thickness; too fast, and the cut may be incomplete, too slow, and overheating could occur. Set the current based on the material’s thickness, with higher amperage increasing speed but potentially reducing precision. Maintain a consistent torch height for smooth cuts, using an automatic height control system if available. Set the gas flow rate according to the manufacturer’s recommendations.

Once set up, power on the machine and load the cutting program. Perform a test cut on a scrap piece to ensure the settings are correct. During cutting, monitor the process closely, watching for irregularities like slag buildup. After cutting, inspect the edges to confirm quality. Regular maintenance, such as cleaning the torch and checking consumables, ensures consistent performance. By mastering these steps, you can achieve precise cuts and maximize efficiency in your metal fabrication projects.

Recent Posts

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.