Introduction

The wide application of laser cutting machines and the smoke and dust problems they produce Laser cutting machines play a vital role in modern industrial production, and their applications are wide-ranging, involving metal processing, machinery manufacturing, electronic equipment production and other fields. However, along with the popularization of laser cutting technology and the improvement of efficiency, the smoke and dust generated during the operation of the equipment is also becoming more and more prominent, and has become an environmental problem that needs to be solved urgently. Soot pollution not only has a serious impact on the working environment, but also poses a potential threat to the health of the staff in the long run. Therefore, it is of great practical significance to explore and implement effective fume control measures to maintain the cleanliness of the workplace, protect the health of workers, and extend the service life of equipment.

The impact of fume pollution on the working environment and health

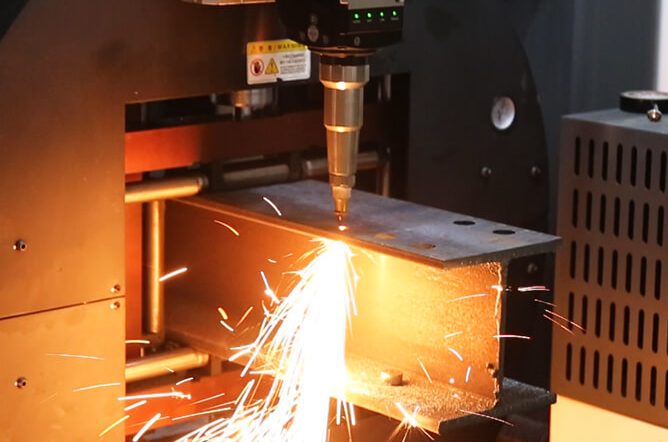

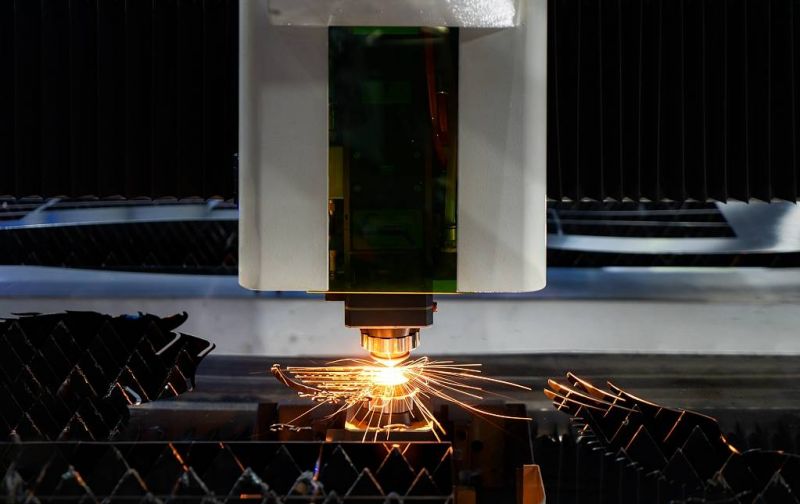

Laser cutting as a highly efficient means of precision processing, the use of high energy density of the laser beam on the surface of the material to produce localized melting, followed by the use of airflow to blow the molten material away from the processing area, to achieve the purpose of cutting. In this process, laser cutting soot generated mainly from material evaporation, melting and gas chemical reaction. The fine particles in the soot will not only reduce the air quality of the working area and affect the health of the respiratory system of the workers, but also may enter the blood circulation through the respiratory system, which may be harmful to the organs of the whole body. At the same time, soot may also cause corrosion to the internal structure of the laser cutting machine, affecting the normal operation and maintenance cycle of the equipment, shortening the service life of the equipment.

The importance of solving the problem of soot pollution

In view of this, it is particularly important to solve the problem of soot pollution generated during the laser cutting process. Effective smoke and dust control system can not only reduce air pollution in the workplace and improve the working environment of workers, but also reduce the maintenance cost and frequency of equipment and improve productivity. Therefore, the research and application of fume capture and purification technology is an important part of realizing the green and sustainable development of laser cutting machine. Only from the source to control and manage fume pollution, in order to ensure the health of workers at the same time, to protect the stable operation of the laser cutting machine and production quality, and thus promote the healthy and sustainable development of the industry as a whole.

Hazards of smoke and dust pollution

Impact on human health

Soot pollution is a common environmental problem, its impact on human health should not be ignored. Harmful substances contained in soot, such as fine particulate matter, heavy metals and organic pollutants, can cause serious damage to the human respiratory system, cardiovascular system and other organs. With long-term exposure to soot, people may suffer health risks such as respiratory diseases, cardiovascular diseases, and reduced immune system function.

Damage to laser cutting equipment

Effects of soot on laser heads and other components

Soot pollution not only poses a threat to human health, but also causes damage to laser cutting equipment. Particles and harmful substances in soot can adhere to the surface of laser cutting equipment, resulting in reduced performance and shorter service life. Especially the laser head and other key components, once contaminated by soot, will seriously affect the cutting effect and stability of the equipment.

Increase in equipment maintenance and failure rate

Particles and harmful substances in soot can easily block the ventilation holes of the laser head, leading to overheating of the laser head, which in turn affects the normal operation of the equipment. In addition, soot can cause malfunctions in the laser head's optical system, reducing cutting accuracy. For other components, soot pollution may also lead to an increase in equipment maintenance and failure rate, increasing the operating costs of enterprises. Soot pollution can lead to an increase in the frequency of laser cutting equipment maintenance. The equipment maintenance process requires cleaning and replacement of the laser head and other components, which undoubtedly increases the maintenance cost of the enterprise. At the same time, soot pollution may also lead to an increase in equipment failure rate, affecting the productivity of the enterprise. Equipment failure will not only lead to production interruption, but also need to spend a lot of time and money for repair, bringing serious economic losses to the enterprise.

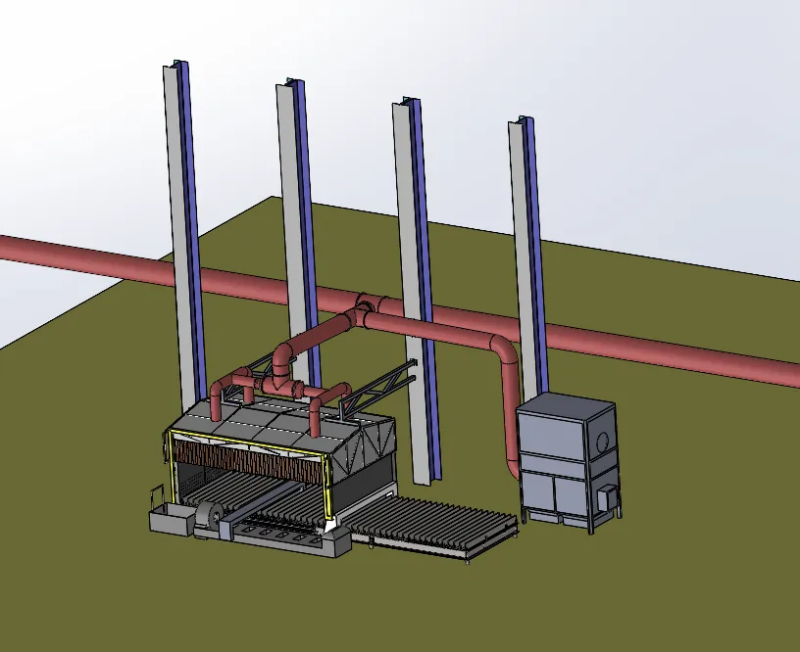

Choose the right dust removal equipment

Importance of dust removal equipment when purchasing laser cutting machines

Choosing the right dust removal equipment is one of the key links to ensure the normal operation of the laser cutting machine. In the purchase of laser cutting machine, supporting the choice of dust removal equipment is particularly important. The right dust removal equipment can not only effectively improve the cutting quality, but also ensure the cleanliness of the working environment and protect the health of the operators. Therefore, in the purchase of laser cutting machine, how to choose the appropriate dust removal equipment has become a problem that can not be ignored.

How to choose the right dust removal equipment

First of all, we need to understand the different types of dust removal equipment and their characteristics. At present, there are several types of dust collectors on the market, such as bag filter, wet dust collector, electrostatic precipitator (ESP) and so on. The bag filter has high dust removal efficiency and is suitable for handling fine particles; the wet dust collector moistens the dust by spraying water and is suitable for handling dust with high humidity; and the ESP separates the dust through the force of the electric field, which has the advantages of large handling capacity and low energy consumption.

When choosing the suitable dust removal equipment, you need to consider the following factors:

- cutting materials: cutting of different materials will produce different types of dust, understanding the cutting materials and dust characteristics will help to choose the right dust removal equipment.

- cutting speed: cutting speed affects the amount of dust generated, high-speed cutting dust generated by relatively small, the need for dust removal equipment is relatively small.

- working environment: the working environment of the temperature, humidity, space size and other factors will affect the choice of dust removal equipment.

- Budget: there is a certain trade-off between the price and performance of dust removal equipment, and you need to choose the most cost-effective equipment within the budget.

- Maintenance cost: different types of dust removal equipment maintenance costs vary, the choice should be fully considered when the equipment maintenance convenience and cost.

In summary, the selection of suitable dust removal equipment needs to consider a variety of factors comprehensively. When purchasing a laser cutting machine, pay attention to the choice of dust removal equipment to ensure the quality of cutting and operator safety. At the same time, understanding the advantages and disadvantages of different types of dust removal equipment helps to meet the actual needs better. In practical application, the most suitable dust removal equipment can be selected according to factors such as cutting materials, cutting speed, working environment, budget and maintenance costs, etc., to provide a clean and efficient working environment for the laser cutting machine.

Conclusion

Laser cutting machines play a vital role in modern industrial production, and their applications are wide-ranging, involving metal processing, machinery manufacturing, electronic equipment production and other fields. However, along with the popularization of laser cutting technology and the improvement of efficiency, the problem of smoke and dust generated during the operation of the equipment is also becoming more and more prominent, and has become an environmental problem that needs to be solved urgently. Soot pollution not only has a serious impact on the working environment, but also poses a potential threat to the health of the staff in the long run. Therefore, it is of great practical significance to explore and implement effective soot control measures to maintain the cleanliness of the workplace, protect workers' health, and extend the service life of equipment.

In view of this, it is particularly important to solve the problem of fume pollution generated during the laser cutting process. Effective smoke control system can not only reduce air pollution in the workplace, improve the working environment of workers, but also reduce the cost and frequency of equipment maintenance, improve productivity. Therefore, the research and application of fume capture and purification technology is an important part of realizing the green and sustainable development of laser cutting machine. Only from the source to control and manage fume pollution, in order to ensure the health of workers at the same time, to protect the stable operation of the laser cutting machine and production quality, and thus promote the healthy and sustainable development of the industry as a whole.

About Us

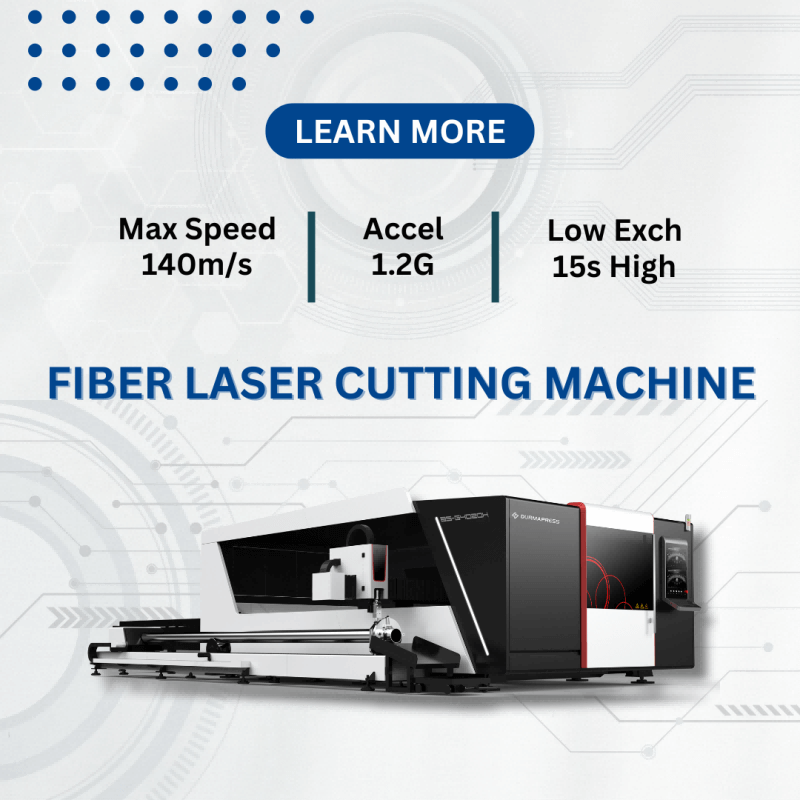

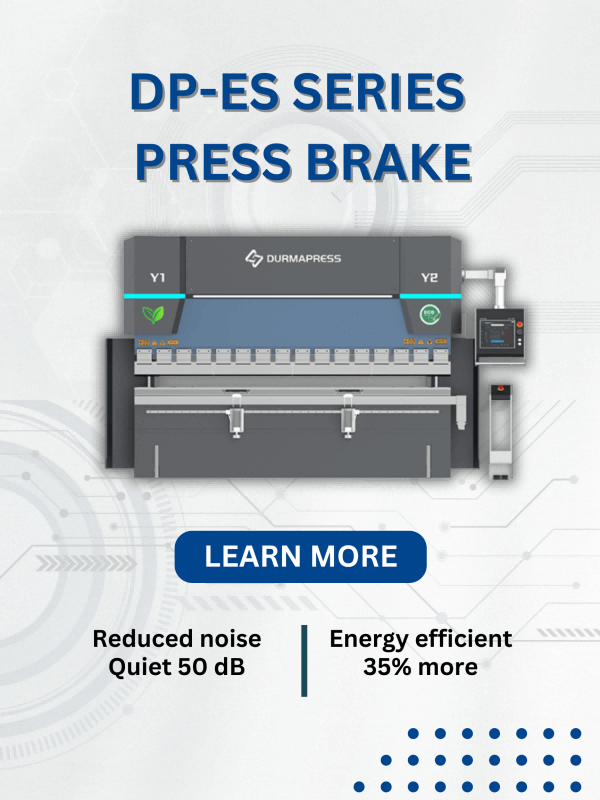

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)