What are the elements that operate the punch press to follow?

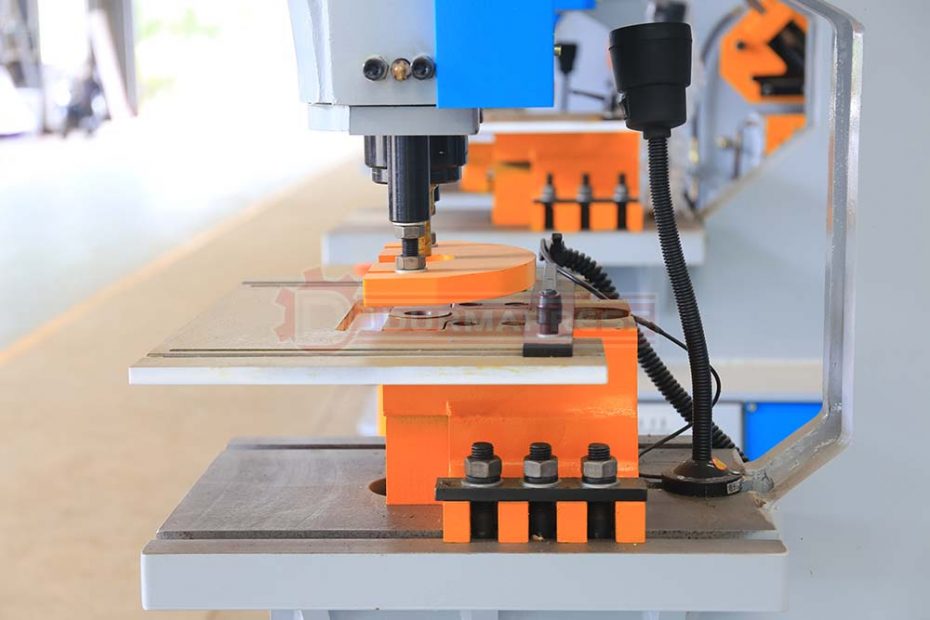

This is the relevant question we are going to talk about in this issue J23-63T punch press machine .

The answer to this question is in the following description, which can be summarized as follows:

1. Protective cover must be installed for transmission parts exposed to the J23-63T punch press machine .

It is forbidden to start or test when removing the protective cover.

2, before starting the press should check whether the main fastening screws are loose, whether the mold is cracked,

whether the control mechanism, automatic stop device, clutch, brake is normal,

whether the lubrication system is blocked or lack of oil. You can run tests in an empty car if necessary.

3, the installation of the mold must open the slider to the bottom dead point, the closing height must be correct,

as far as possible to avoid eccentric load; The mould must be firmly fastened and pressure tested.

4, work attention should be focused, do not put hands, tools and other objects into the danger zone.

Small parts must be operated with special tools. When the mold is stuck to the blank, only the tool is allowed to release it.

5. If the press is found to run abnormally or have abnormal sound, the feeding should be stopped immediately and the reason should be checked.

If the rotating parts are loose, the control device is out of order, the mold is loose and damaged, it should be stopped for repair.

6. When each workpiece is finished, the hand or foot must leave the button or pedal to prevent misoperation.

7, more than two people operation, should be ordered to drive, pay attention to coordination.

Before going off work, the mold should be placed, disconnected from the power supply, and necessary cleaning.

The above is the main content of this period, I hope you can grasp the above content in time, but also hope that you can take it seriously.