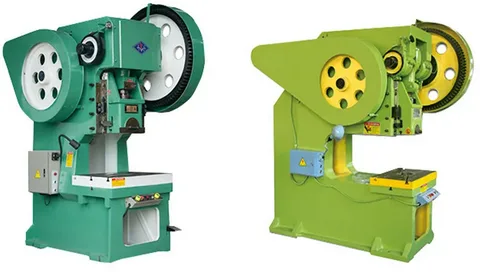

1. Calibration between slide block and guide rail J23-40T punch press machine

The clearance adjustment between the slide block and the guide rail of the press is mainly for accuracy,

and the phenomenon of heating will be generated when the adjustment is too tight.

General minicomputer each side of 0.02~0.05mm, mainframe each side in 0.03~0.20mm.

2. Locking of sliding block connecting rod J23-40T punch press machine

Because of long-term use or overload, the connecting rod will loosen, this state is generally considered to be the occurrence of overload;

Then there is oil leaching in the binding part, which may also be the occurrence of overload;

This condition must be adjusted in time to the locking degree of the connecting rod locking mother, because it is related to safety issues.

3. Brake and clutch maintenance

The brake and clutch of the punching machine are important parts for the safety of the operation of the punching machine.

It is the cause of major safety accidents, so we must understand its basic structure, and confirm its safety performance before operation every day,

and find abnormal conditions (such as: Press slider can not stop at the specified position, abnormal sound, abnormal vibration, slider slow action, etc.) report maintenance in time.

The phenomenon of detachment

The phenomenon of press detachment generally occurs at the bottom dead point, when the upper and lower die is closed,

resulting in the normal operation of the slider. At this time, you can make the motor reverse operation and raise the pressure of air pressure,

the operation selection button to "inch" state, will be pulled up the top dead point slider.