Hydraulic plate shear machine adopts triangular body on the tool rest structure, blade gap adjustable, different thickness of the plate shear is the need to adjust the blade gap,

the machine's shear control through the digital control system. Numerical control system effectively controls the travel range of the rear baffle,

the rear baffle is through the ball screw drive to complete the back and forth movement of the baffle.

Through the encoder to complete precise positioning, plate shearing process, through the numerical control system

digital input and output to complete the control and rotation of the machine, peg PEG4000 foot switch control tool rest up and down shearing,

easy to use, accurate and high. Optional CNC feeding platform and palletizing installation. CNC rear stopper automatic control

is suitable for sheet metal processing industry sheared blanking.

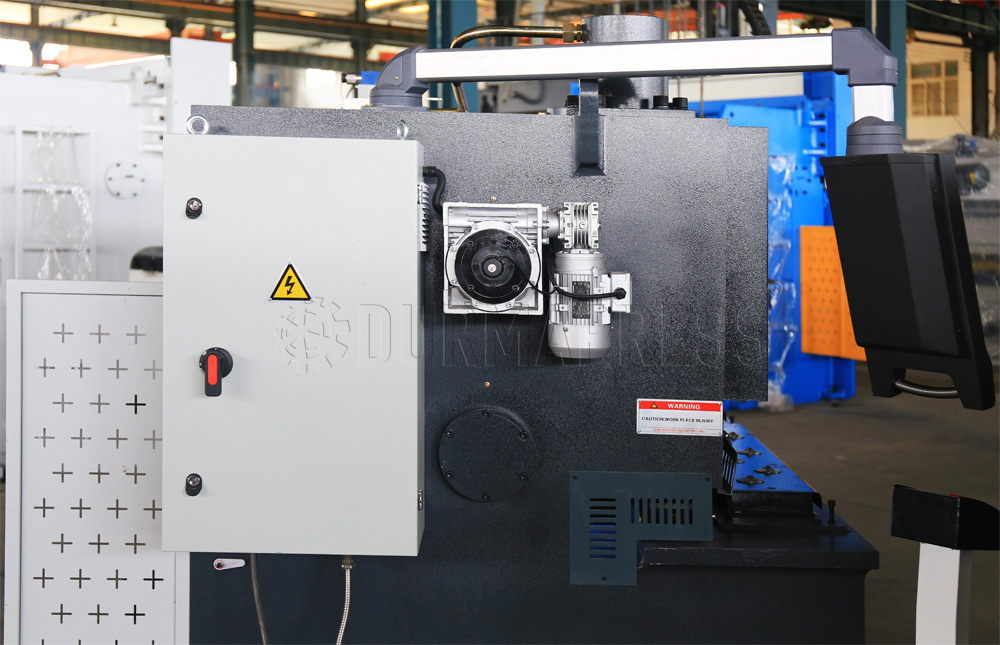

The 4-meter gate shears cut 12mm thick sheets. 12X4000 hydraulic gate shearing machine all steel welding structure,

comprehensive treatment (vibration aging, thermal treatment) eliminate internal stress, has a good rigidity and stability;

Advanced integrated hydraulic system, good reliability; Eliminate rail clearance, improve shear quality.

Motorized rear stop material, manual fine tuning, digital display; The blade gap is adjusted by hand wheel,

which is fast, accurate and convenient. Rectangular blade, four edges can be used, long service life.

Adjustable shear Angle to reduce sheet distortion; The upper tool rest adopts the inwardly inclined structure,

which is convenient for blanking and can improve the accuracy of work; Segmented shear function; With lighting installation function.