Hydraulic CNC bending machine comprises a support table and splint. The worktable is composed of a base and a pressure plate.

The base is hinged to the splint. The base consists of a housing, a coil and a cover. Place it in a groove in the seat housing,

the top of which is covered with a cover plate.When in use, the wire is energized to the coil,

which generates gravity on the platen to achieve the clamping between the platen and the base.

By electromagnetic clamping, the platen can be made into various workpieces, and the workpieces with side walls can be processed.

Bending machine can change the bending machine mold to meet the needs of various workpiece.

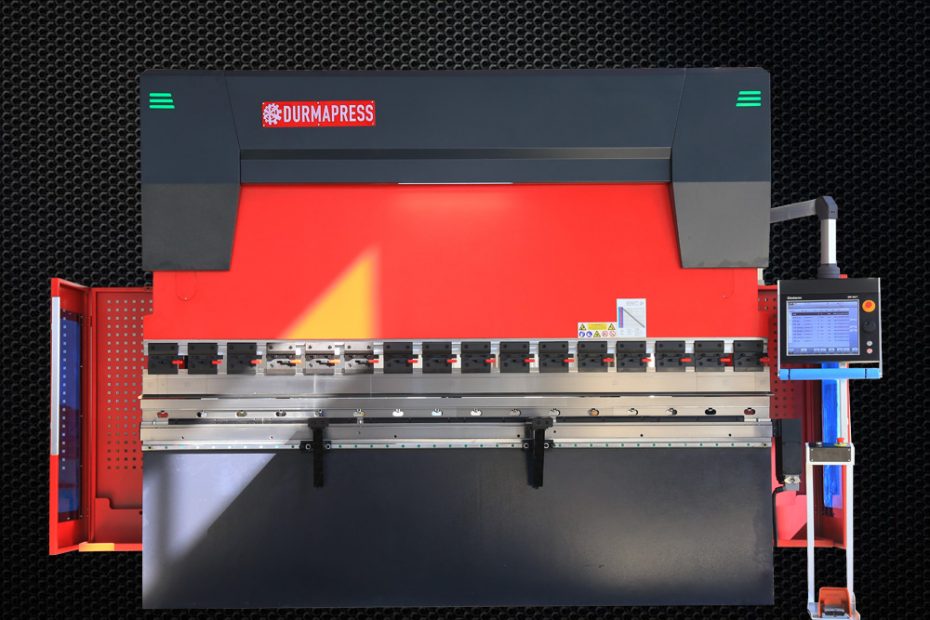

Maanshan DurMAPress CNC bending machine advantages:

1. According to the principle of hydraulic transmission, the implementation parts (cylinder, plunger or piston) simple structure,

structure is easy to complete the larger work pressure of the larger workspace and longer work stroke,

so the high flexibility is easy to suppress large parts or longer and higher workpiece.

2. The extra pressure of CNC bending machine may appear at any position of the outer stroke.

Pressure can be maintained for a long time at the next transition point, which is very demanding for many processes.

3. The total stroke of the slide block can be arbitrarily changed within a certain range,

and the next turning point of the slide block stroke can be controlled or modified according to the pressure or stroke position.