Hydraulic bending machine is the basic equipment of sheet metal processing, is also a common kind of general equipment, the amount of use is large, then mechanical equipment in the long-term use will appear such and such problems, xiaobian for you summed up a part of the problem prone to hydraulic bending machine, and its solution. For your information.

(1) The damping hole is blocked, and the system has no main pressure relief valve failure. Improper adjustment, spring broken, valve core conical seal is not good or valve core stuck. Clean, grind, adjust, repair or replace the relief valve. Solenoid directional valve is faulty, valve core stuck. Clean, grind or replace the slide valve.

(2) the slider does not act but can rely on the weight of the axial piston pump can not supply pressure oil: oil shortage; The motor failed to start after checking the start button. Ac contactors and thermal relays and motors; The plunger pump itself failure, inspection or replacement of the plunger pump.

(3) Main oil overflow valve failure. It may be that the damping hole is blocked and improperly adjusted, the spring is broken or the valve core is rusted and stuck. The relief valve needs to be adjusted, repaired or replaced.

(4) The slider is not parallel to tighten the handwheel of the air release valve, and the air in the balance cylinder. After filling oil and reducing air, loosen the valve.

(5) Leakage of the vent valve, dismantle and check the seal of the vent valve cone.

(6) the check valve has internal leakage, check the check valve cone seal, grinding cone sealing surface with line contact is better or change the check valve.

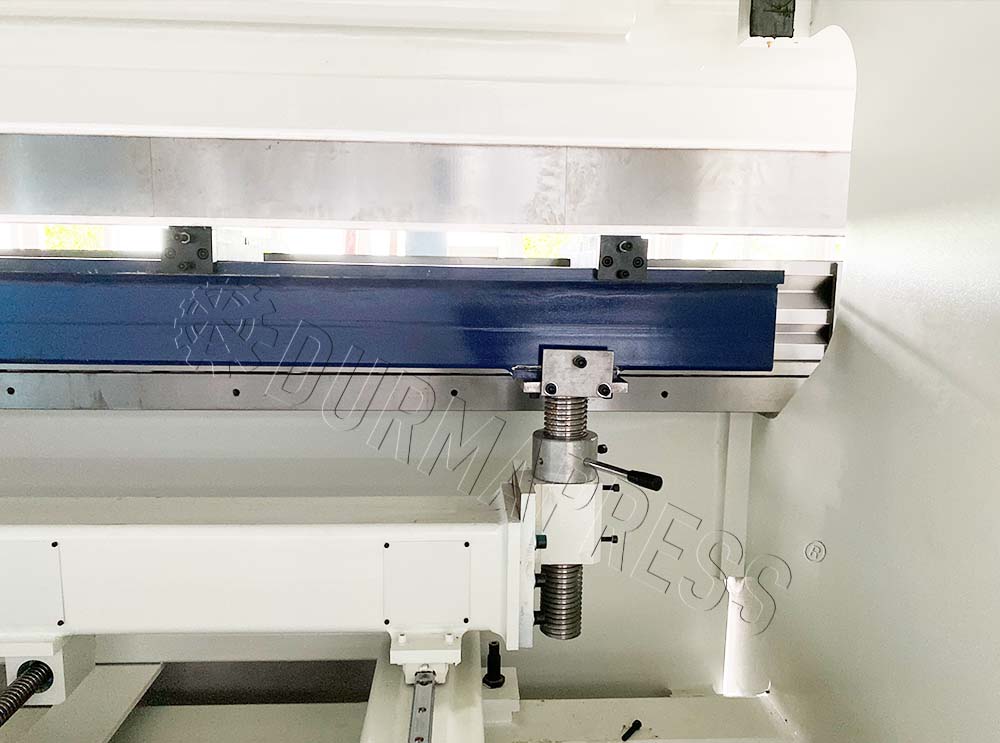

(7) Bending machine balance cylinder piston rod head inclined iron fastening screw loose, check and piston rod head inclined iron screw.

2. CNC bending machine maintenance method

(1) the slider can not go down the electromagnetic directional valve can not be reversed. Repair or replace the shell fixing screw loose. Check and tighten the circuit; Reversing valve core stuck.Clean, grind or replace the slide valve.

(2) one-way throttle valve core stuck or closed dead maintenance and cleaning.

(3) The sliding block can only be repaired or replaced to tighten the fixing screw of the shell. The solenoid directional valve cannot be reversed. Valve core stuck. Cleaning grinding or slide valve; No action or loosening of shell fixing screws. Check the circuit.

(4) the valve core of the hydraulic control check valve is stuck. For maintenance, the liquid control check valve cannot be opened. Wash or replace.

(5) The spring may be loose. Tighten the hand wheel of pressure relay clockwise, the pressure relay is faulty. Press the spring.

(6) Piston cylinder piston seal ring wear seriously. Replace the seal ring.