features

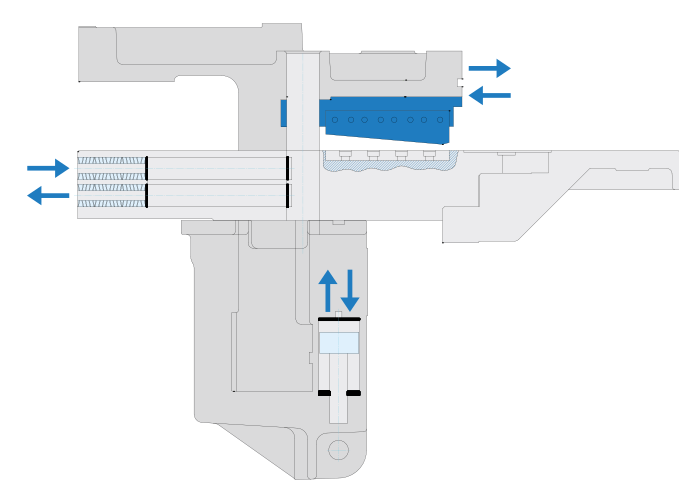

- Use hydraulic under-drive type

- Steel plate of whole machine adopts overall welding structure

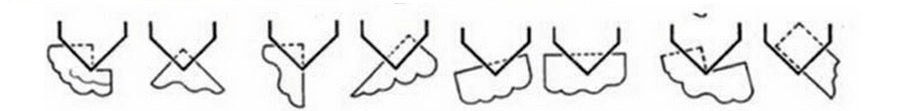

- 90°fixed-angle cutting

- Single-stage & Step-stage operation function select

- Positioning device of variable-angle-bit

- Centralized lubrication system

durmapress

Description of Main Components

Standard accessories for Hydraulic Angle Notching Machine

Machine Body

The steel plate of the whole machine adopts an integral welded structure, which is very strong and stable, and prolongs the working life of the whole machine.

control panel

The control panel is used to start and stop the machine, adjust cutting parameters, and monitor operational conditions, ensuring precise and safe operation of the notching process.

Reversible upper blades

Our 30° and 60° upper blades are reversible, and are made from highspeed steel for exceptional durability and long life.

Blade locking system

Hydraulic 5-cylinder system positively fixes any selected blade angle with the turn of a switch - even when cutting heavy metals.

Main Motor

The main motor is the primary driving component that powers the hydraulic system. This motor is responsible for generating the necessary hydraulic pressure to operate the notching blades, ensuring precise and efficient cutting of materials at a fixed 90-degree angle.

Auto Lubrication System

The main function of this system is to ensure that the various moving parts of the machine are continuously and properly lubricated during operation, thereby reducing friction and wear, extending the service life of the machine, and maintaining efficient operation of the machine.

Why choose us

Get Burr-Free quality with DURMAPRESS’s automatic blade gap adjustment.

With each cut, Durmapress’s patented automatic blade gap adjustment system instantly sets the lateral distance between the upper and lower cutting blades for optimum cutting. This saves time that would otherwise be spent in machine adjustment or in burr removal. It also lengthens blade life, while eliminating the costly material waste normally associated with “trial and error” machine adjustment.

- 20+ Years of Experience

- Personalized customized machines

- Perfect after-sales system

- 24/7 Availability

Get more details

Why To Choose Hydraulic 90°Fixed Angle Notching Machine?

1

Precision Cutting

The fixed 90° angle ensures consistent and accurate cuts, ideal for creating clean corners and joints in metal sheets.

2

Powerful Performance

Equipped with a robust hydraulic system, it provides the necessary force for cutting through various metal thicknesses with ease.

3

Durability

Constructed with high-quality materials and components, this machine is designed for long-term use and reliability in demanding industrial environments.

4

Ease of Use

User-friendly controls and straightforward operation make it accessible for both novice and experienced operators.

5

Versatility

Suitable for a wide range of applications in industries such as automotive, aerospace, and construction, enhancing overall productivity.

6

Safety Features

Incorporates advanced safety mechanisms to protect operators and ensure safe operation.

90° Fixed Angle Cutting

High manufacturability and wider application range

This model can notch a 90 degree angle in 4mm mild steel with maximum length of 220mm. The machine has a large working table with 2 adjustable quick set stops and scales. The blade area is covered with a plexi cover to guard the operator. The machine is delivered as a ready-to-use package with full oil tank, manual and 1 set of blades installed.

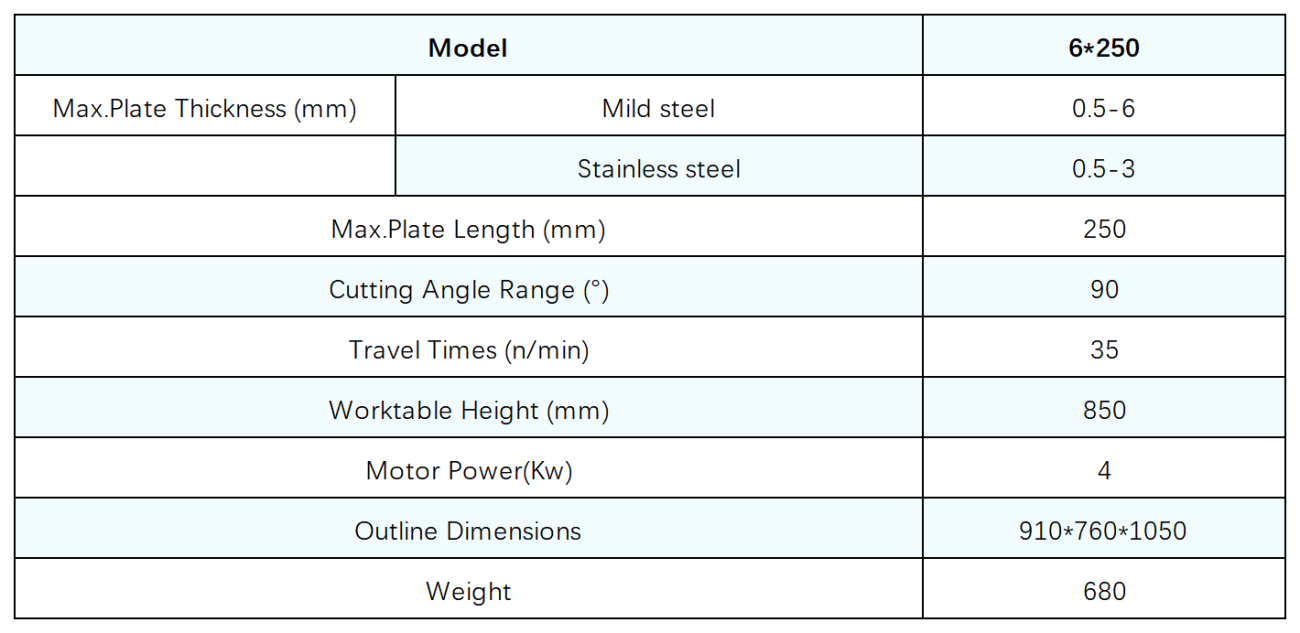

Technical Data

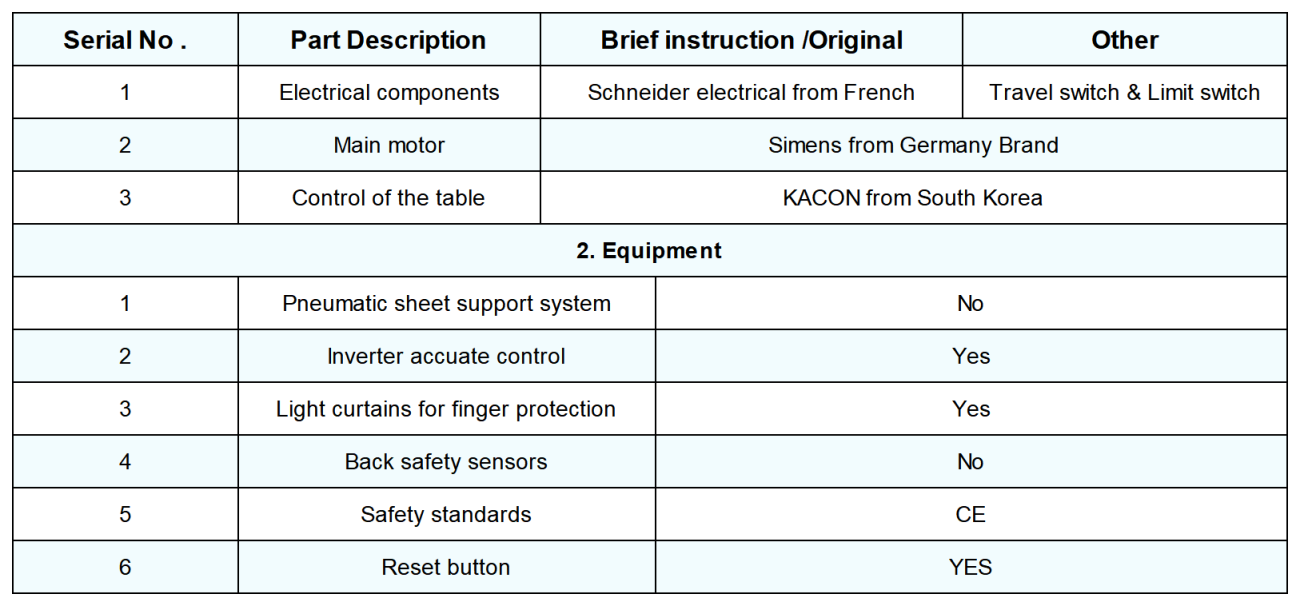

Main Components

Technical Data

Main Components

durmapress factory

Watch the Video

Contact us

Location

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Our Hours

7/24

Follow Us