DSP Laser Safety System Overview

Definition and Importance in Press Brake Operation

A DSP laser safety system is a safety device that protects the operator by controlling the laser beam through digital signal processing technology. It plays a vital role in bending machine operation by detecting any objects that may enter the danger zone during the bending process and stopping the machine in time to avoid accidents.

Definition and Importance in Press Brake Operation

Improved operational safety: real-time monitoring and prevention of accidental access to hazardous areas.

Increased productivity: reduces downtime and ensures production continuity.

Precise control: Provides precise safety zone settings and sensitivity adjustments to suit different production needs.

Compliance with safety standards: Compliance with international safety standards and enhances the safety image of your organization.

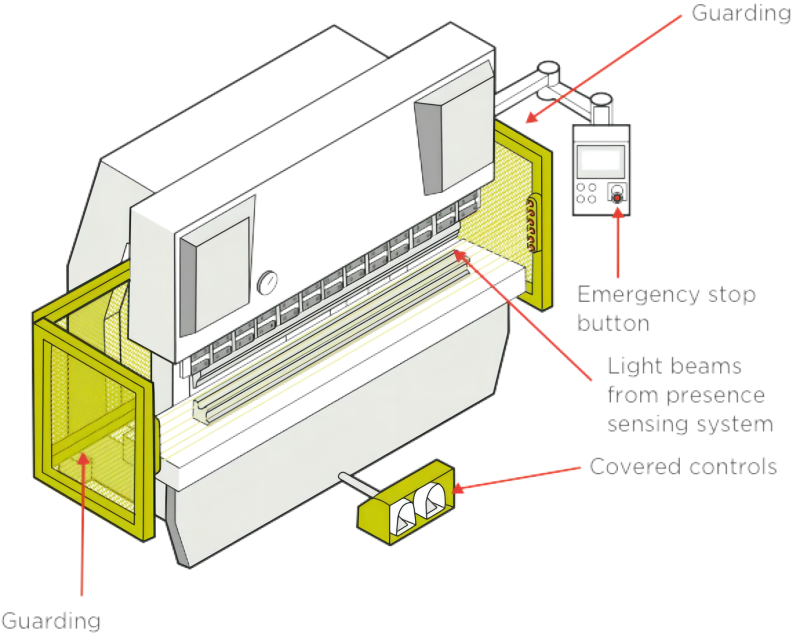

Learn about DSP laser safety system components

Laser transmitters and receivers

The laser transmitter and receiver are the core components of the DSP laser safety system and detect obstacles by transmitting and receiving a laser beam. As soon as the laser beam is blocked, the system responds immediately.

Control Unit

The control unit is responsible for processing the signals from the laser transmitter and receiver and making control decisions accordingly. It is the brain of the system and ensures the reliable operation of the system.

Functions of the central control unit

The main functions of the central control unit include signal processing, safety parameter setting, system status monitoring and fault diagnosis. It is the core part of the system and determines the overall performance of the system.

Safety interface

The safety interface is used to connect the DSP laser safety system with the control system of the bending machine to ensure data communication and cooperative work between the two.

Connection to the bending machine control system

The DSP laser safety system is connected to the control system of the bending machine through the safety interface, realizing real-time monitoring and control and ensuring a quick response in the event of a dangerous situation.

Connection to the press brake control system

Evaluating the press brake setup

Before installing the DSP laser safety system, a detailed assessment of the existing setup of the bending machine is required to ensure seamless integration of the new system.

Required Tools and Safety Precautions

Prepare the tools required for installation, including screwdrivers, wrenches, cables and cable clamps, etc., while following safety procedures and wearing appropriate protective equipment.

Step-by-Step Installation Guide

- Determine the mounting positions of the laser transmitter and receiver, making sure they are on the same level.

- Secure the laser transmitter and receiver in their designated locations using brackets and set screws.

- Adjust the laser transmitter and receiver so that they are accurately aligned.

Mounting the laser assembly

- Determine the mounting positions of the laser transmitter and receiver to ensure that they are on the same level.

- Secure the laser transmitter and receiver in the specified position using the bracket and set screws.

- Adjust the laser transmitter and receiver so that they are accurately aligned.

Connecting the control unit

- Connect the laser transmitter and receiver to the control unit via cables.

- Ensure that the connection is secure and protected from loose or damaged cables.

- Integration with the bending machine system.

System testing

Initial power-up and calibration

Start the DSP Laser Safety System and perform an initial power-up test.

Follow system prompts for calibration to ensure that the laser beam is accurately aligned and working properly.

Functional testing and tuning

- Perform a full functional test to ensure all components are functioning properly.

- Make necessary adjustments based on test results to optimize system performance.

Operating Instructions

How to turn the DSP laser system on and off

Press the power button to turn on the DSP laser safety system.When shutdown is required, press the power button and the system is safely shut down.

Adjusting safety parameters

Enter the system setting interface and select the safety parameter setting.Adjust the safe area and sensitivity according to the actual need

Setting Safe Area

In the system setting interface, select the safety area setting. Set the appropriate safety zone according to the working range of the bending machine.

Configure sensitivity and response time

Enter the system setting interface and select the sensitivity and response time settings. Adjust the sensitivity and response time according to the production demand to ensure the best protection effect.

Troubleshooting Common Problems

Laser alignment problems

How to realign the laser beam

Check that the laser transmitter and receiver are mounted in the correct position.Adjust the bracket and set screws to ensure the laser beam is accurately aligned.

Control Unit Errors

- Diagnosing and fixing control unit errors

- Check for proper power and connections to the control unit.

- Check the error codes and troubleshoot accordingly according to the manual.

System Faults

- Power supply faults: Check the power connections and voltage to ensure that the power supply is normal.

- Communication faults: Check interface and cable connections to ensure normal data communication.

- Damaged components: Replace damaged components to ensure normal system operation.

Conclusion

Summary of Benefits

The safety and efficiency of bending machine operations can be significantly improved with the DSP Laser Safety System. Real-time monitoring and precise control ensures operator safety and increases productivity. Regular maintenance and proper operation extends the life of the system and ensures long-term reliable operation.

Review the key benefits of using the DSP Laser Safety System

Using the DSP Laser Safety System significantly improves the safety and efficiency of bending machine operations. Real-time monitoring and precise control ensures operator safety and increases productivity. Regular maintenance and proper operation extends the life of the system and ensures long-term reliable operation.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)