What is an industrial robot?

If you are a manufacturer who wants robots to work in your factory, you can think of an industrial robot as an "automatically controlled manipulator" (this explanation is based on the definition of the International Federation of Robotics, slightly abridged). Robots come in many forms, and the term "robot" is mainly used below to refer to robotic arms. Robotic arms are also called industrial robots and are responsible for achieving specific production tasks.

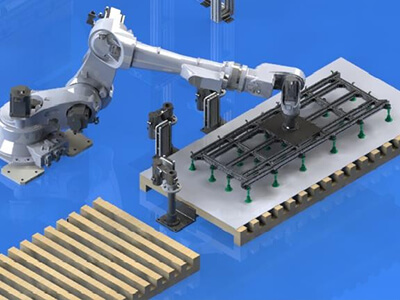

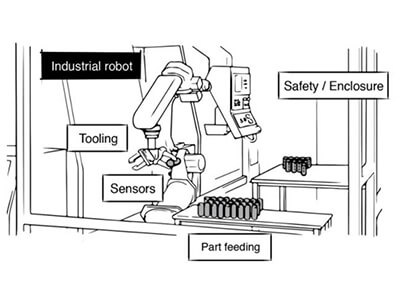

However, a robotic arm alone can't do much; you need other components to work with it, which is why it makes more sense to talk about a robotic cell rather than a robot. Generally speaking, a cell is any station in a manufacturing process, such as a station on a production line that performs a specific operation.

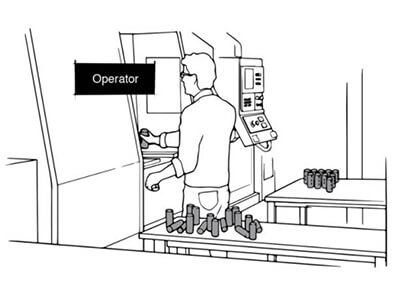

If the operations at a workstation are performed by humans, the workstation is called a manual unit (as shown in the figure).If the operations on the workstation are done by humans, the workstation is called a manual cell (as shown in the figure). Below is an overall view of a manual cell and a robot cell.

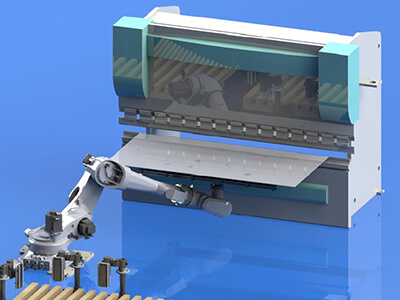

When a factory installs a robotic cell, their primary intention is to automate a process. This process may currently be done in a manual cell, or it may be an entirely new function. As you may have guessed by now, a robotic cell is a workstation that contains a robot.

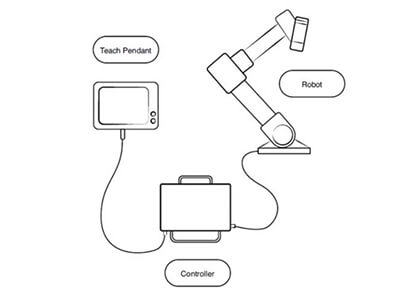

When you buy a robotic arm, there are two important elements involved: the controller, which is the computer that drives its movements, and the teach pendant, which is the user interface that operators use to program the robot.You can think of the controller as the main chassis of a desktop computer, and the teach pendant as your monitor and keyboard.

Install the robot arm, controller and teaching box

What's on the robot's wrist, what's on the robot's body, it all depends on the application. But no matter what the application is, the robot always needs other parts to work properly.These components include end-of-arm tools (grippers, welding guns, polishing heads, etc.) and sensors (such as torque sensors, safety sensors, vision systems, etc.). When installing the robot in a production workshop, you need to fix it to a solid surface. The installation may also require the addition of a parts feeder, protective devices such as guardrails, etc.A robotic cell consists of more than just hardware. While the controller comes with some pre-installed software, you have to write the program - the table of instructions that the robot follows to perform a specific task.

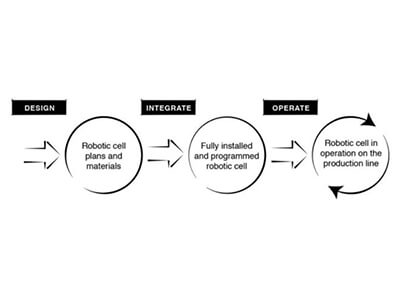

The following diagram shows the main steps of the robotic cell deployment process: design, integration, and operation.

The design phase includes the planning and materials needed to switch all tasks from manual (or primitive) processes to the robotic cell.

Next, the integration phase is where the parts of the robotic cell are assembled, programmed, and installed on the production line.

The operation phase represents the ultimate goal of deployment: the robotic cell continues to work properly. When you buy a "robot" from a robotics company, you usually only get the robot arm, controller, and teach pendant. Most robotics companies provide other hardware and software accessories, but these hardware and software do not cover all possible applications.

Suppliers in the industrial robot industry are very fragmented

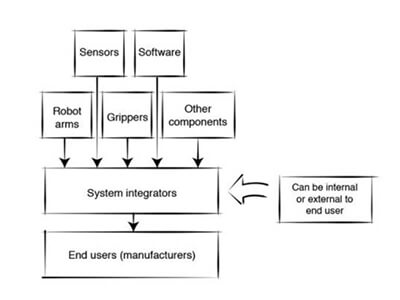

The structure of the industrial robot ecosystem is shown in the figure below. The dispersion of suppliers is also the biggest difference between the industrial robot industry and other industries. Different industrial robot integrators provide different solutions. Whoever deploys the robot unit needs to integrate these solutions together during the design and integration phase. The design and integration phase can be completed by the internal team of the manufacturer who purchased the robot, or by an external contractor (also known as a system integrator).

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)