With the rapid development of sheet metal production towards automation and intelligence, the application of robot bending units and panel benders is becoming more and more popular. So how do companies choose?To know how to choose, we must first understand the problems that need to be solved in the sheet metal bending industry and how the robot bending unit and the panel bender perform sheet metal bending?

Problems that the sheet metal industry currently needs to solve

Let's first talk about the problems that need to be solved in the sheet metal bending industry:First, it is impossible to achieve multiple varieties, small batches, and fast switching.Second, the bending processing accuracy of high-precision workpieces in the sheet metal industry is low and the quality is unstable.Third, sheet metal bending operators are scarce and the labor intensity of workers is high.Fourth, personnel costs, safety hazards, process layout, and management operations.

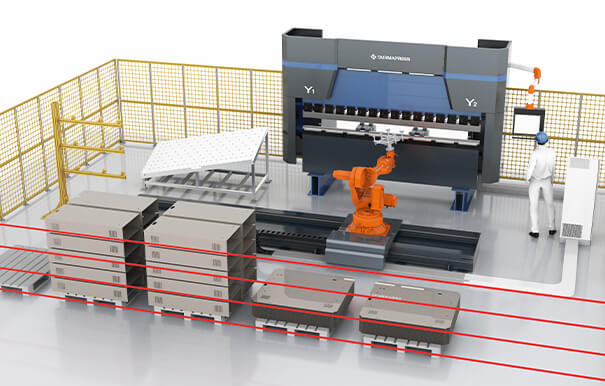

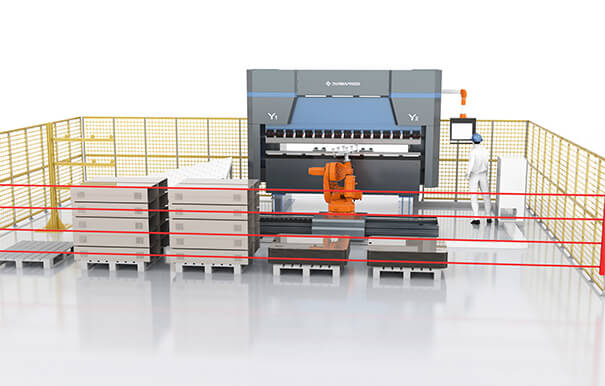

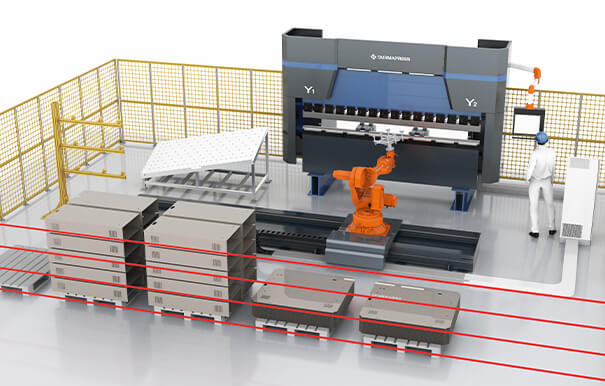

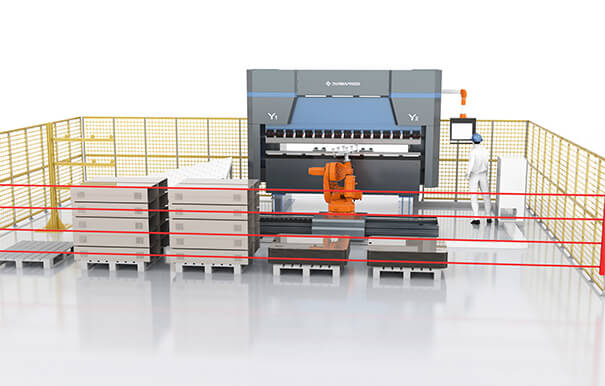

Robotic bending cell

1. Characteristics of robot bending unit system

Features of the robot bending unit system Multi-variety production, product switching does not require first piece testing, no programming teaching, and product model production switching can be completed within 10 minutes. No professional technicians are required, only operators with strong learning ability and good at research are needed. Product accuracy can be 100% guaranteed. Component integration ensures that the system is safe and reliable. Reasonable layout and grand appearance.

2.Technical features of robot bending unit

In the design and development of the robot bending unit, first, we must pay attention to the user's personalized needs and customized characteristics, take customer needs as the top priority, and conduct detailed technical exchanges with customers in the formulation of each technical solution; second, conduct computer simulation analysis on the workpiece processing drawings provided by customers; third, conduct on-site proofing tests on customers' typical workpieces; fourth, conduct classification analysis and data processing on customers' workpieces.After confirming that the above-mentioned procedural work has been completed, the technical plan will be formulated. After the technical plan and plan drawings are approved by the customer, the comprehensive design can be carried out.

The bending machine frame of the robot bending unit inherits the material characteristics of Italian sheet metal equipment. The material is 45# steel or Q345B, which has the characteristics of good comprehensive mechanical properties, good rigidity, high strength and good stability.

Traditional bending machines generally use welded frames, including left and right columns, lower beams (work tables), oil tanks and supporting square beams, which adopt an integral welded structure. However, the frame of the bending machine in the robot bending unit does not use a welded frame structure, but uses frame riveting technology. The lower beam (work table) and the column are fastened with high-strength steel bolts. This flexible connection fully ensures that the fuselage can reduce the stress deformation of the frame to a large extent under high-strength load conditions, and maintain the long-term stability of the machine tool accuracy.Its structural features: ensure that the machine has no welding stress deformation. Improve the machine assembly accuracy. Extend the service life of the machine. Greatly improve the hydraulic compensation accuracy.

In order to ensure high-precision sheet metal bending, sensors are installed on the upper beam (slider) and lower beam (workbench) of the bending machine. When in working state, the deformation of the upper and lower beams is accurately fed back to the CNC system (PC) in real time. After calculation and comparison, the CNC system outputs the corresponding compensation value to drive the compensation cylinder for dynamic compensation to obtain satisfactory part accuracy.

Its compensation technology can ensure that the bending angle is completely consistent throughout the entire length regardless of changes in bending conditions such as plate thickness, length or bending position, eliminating the measurement error of the grating ruler and ensuring machine accuracy. The automatic deflection compensation system simplifies the complex trial bending process under the condition of bending with a certain plate thickness through closed-loop control. Even if the length of the bent workpiece is different or at different positions on the bending machine, it can ensure that the bent workpiece has completely consistent angles and straightness without manual intervention. It can achieve high bending accuracy and stability and complete real-time dynamic compensation.

Bending follow-up technology: During the bending process, the robot bending unit can automatically follow and adjust according to the running speed of the bending machine slider to deal with workpieces of different sizes and thicknesses.

Laser angle measurement technology: The laser angle online measurement system, during the robot automatic bending process, its automatic application and the automatic angle measurement of the built-in laser angle measurement device ensure the accuracy of the bending angle. Its main features are: online detection of the bending angle of the workpiece after rebound through laser. The force detection system automatically calculates the bending rebound amount. The workpiece can automatically adjust the depth according to the width of the lower die. Through the closed-loop laser angle online measurement system, the bending yield rate is guaranteed to reach more than 99.5%.

Robotic automatic gripper and die changing technology: Robotic automatic gripper and die changing is one of the advanced intelligent automated operation technologies of the bending machine. This technology consists of automatic die changing software, robots and die libraries. When the automatic die changing system is selected, the precision bending center can automatically and randomly bend small batches of different products. With the automatic die changing function, the die in the bending machine is no longer a limiting factor, and parts can be handled unmanned throughout the process. The gripper of the robot automatic mechanical device changes the die very quickly and can bend the next batch of parts at any time.

Software and control: Parametric programming, offline programming and production management software are applied in the robot bending unit. At the same time, the bending follow-up, automatic mold change, automatic gripper change, flexible stacking, real-time compensation, plate edge search, flexible flip technology and bus control technology are developed, which greatly meets the technical and software requirements of sheet metal bending for various customers.Compared with traditional bending technology and process, the robot bending unit can increase production efficiency by two times, realize safe unmanned operation, reduce 90% of the original labor, help solve the bottleneck problem of sheet metal processing for users, and fully reflect the advantages of intelligent manufacturing in the sheet metal industry.

panel bender

1.Panel bender characteristics

The FlexBending Center is a universal bending tool with customizability and flexibility. Its automatic bending length setting system provides high productivity and flexibility levels. Its auxiliary tool system makes the bending center a versatile bending machine that can perform a variety of special bends. The modular design allows the integration of other systems for complete automation, such as different loading and unloading systems or other sheet metal processing equipment. Its automation saves time, the panel bending productivity is high, and it is a highly flexible machine capable of automatic part handling.

2.Advantages of panel bender

The panel bender is able to work independently and can efficiently produce parts of various specifications. The universal mold can be automatically adjusted according to the size set by the program without any adjustment time, ensuring the safety of the operator and the quality of the product. The universal bending knife does not require mold change time, it adjusts in real time according to the length of the workpiece to ensure the quality of the workpiece. Since no manual operation is required, the personal safety of the operator is greatly guaranteed. The positioning process is only completed once at the beginning of the entire bending, at the start of the cycle to operate, stop, and rotate the part in a controlled manner. The clamping and rotation of the sheet remain unchanged during the bending cycle, and due to the continuous rotation, the 0.01° angular resolution is guaranteed to ensure high production flexibility. The flexible servo bending center reduces manual intervention to a minimum and makes full use of available resources. After the initial offline programming, it operates completely autonomously.

Summary

Both products can realize bending automation, which is very helpful to improve bending efficiency. They have their own advantages, but also some disadvantages. Different types of enterprises need to choose according to their own conditions, different products and production modes.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)