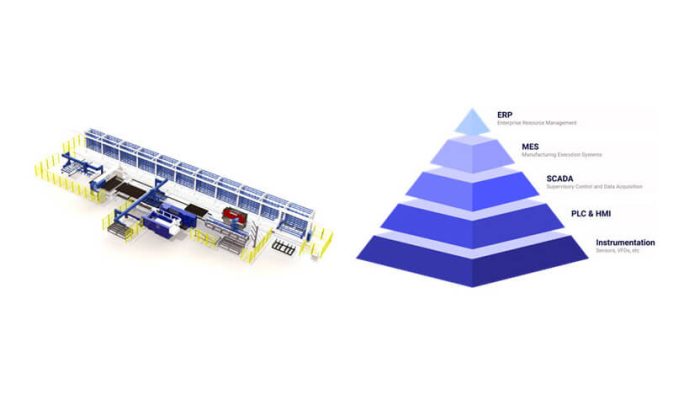

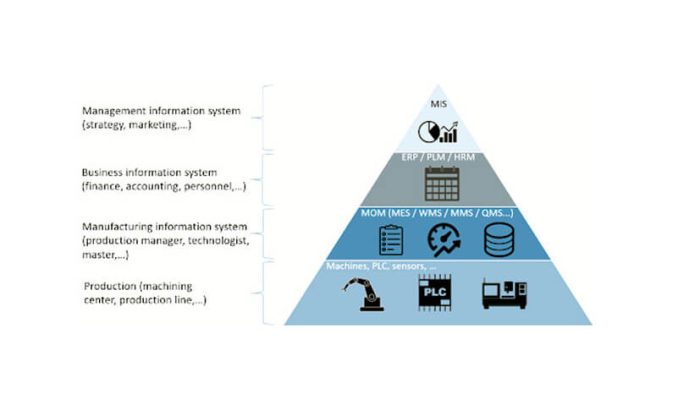

In the sheet metal industry, which involves the forming, processing, and welding of metal sheets to produce various metal products for industries such as electrical appliances, communications, automobiles, and furniture, MES (Manufacturing Execution Systems) plays a pivotal role. Main products include chassis, cabinets, sheet metal parts, and metal cabinets, among others.

Sheet metal processing is a common manufacturing process that, despite the diversity of its classifications and corresponding processing differences, generally involves the application of pressure to deform metal sheets, including cutting, punching, bending, rolling, lamination, and forming.

In the realm of sheet metal, the information needs for MES systems are the same as other workshops, encompassing planning management, production management, material management, quality management, equipment management, and other conventional MES functions. However, the unique aspects of sheet metal processing also reflect some specialized information requirements. Therefore, in the sheet metal industry, the MES system planning, in addition to traditional standard functions, should also focus on the following characteristics in the needs analysis and functional design.

The variety of sheet metal products, their sizes, and the quantity of each finished product order pose challenges for single-item production and batch production coordination. Moreover, the production load of different groups of sheet metal equipment varies significantly. Therefore, the characteristics of batch production and the differences in equipment production capacity are the difficulties and key points in the MES system for sheet metal production scheduling. The scheduling strategy in sheet metal planning should take these two points into account.

In sheet metal processing, the raw materials for punching and cutting are typically metal sheets or coils. To improve the utilization rate of raw materials and reduce waste, many sheet metal processes use material (nesting) software that automatically simulates sheet metal parts on the board and generates material result NC programs for the sheet metal equipment to execute.

In this process, for MES to realize the dispatch and monitoring of sheet metal operations, the system needs to integrate with the nesting software. Through integration, the MES system issues batch grouping rules for sheet metal to the nesting software and obtains nesting feedback results, and relevant data on the execution process of sheet metal operations.

In this process, for MES to realize the dispatch and monitoring of sheet metal operations, the system needs to integrate with the nesting software. Through integration, the MES system issues batch grouping rules for sheet metal to the nesting software and obtains nesting feedback results, and relevant data on the execution process of sheet metal operations.

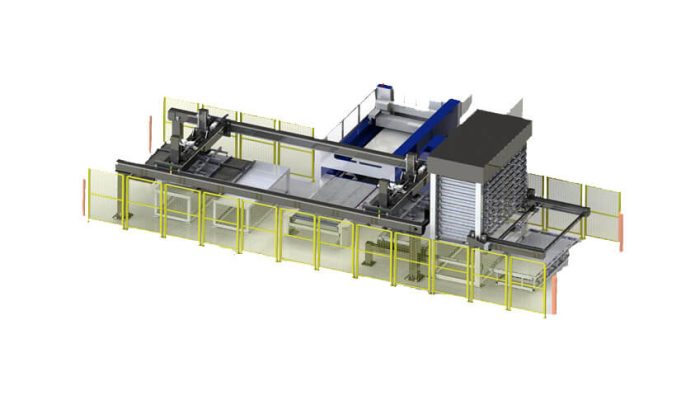

A variety of equipment is used in sheet metal processing. Generally, basic equipment includes shearing machines, CNC punch presses, laser cutting machines, bending machines, drilling machines, uncoiling machines, leveling machines, deburring machines, spot welding machines, and various auxiliary devices.

In the manufacturing industry, press brakes are key production equipment used to form sheet metal parts. With the rise of intelligent manufacturing, the Manufacturing Execution System (MES) serves as the neural center connecting modern factories, playing a crucial role in enhancing the efficiency and production quality of bending machines.

Real-time data monitoring:

The MES system can collect real-time production data from bending machines, including the operating status, output, and quality indicators. This data can help factory managers monitor the production process in real time, identify issues promptly, and take swift action to ensure production efficiency and product quality.

Production planning optimization:

The production plan for bending machines can be optimized through the MES system. The system can intelligently schedule production based on order requirements, raw material supply, and delivery times, ensuring efficient and orderly production activities.

Quality management:

The MES system can also monitor and record the quality control process of bending machines. By collecting and analyzing quality data, the MES can help identify problems in production and provide improvement measures to ensure that the final product meets quality standards.

Maintenance and fault prediction:

The MES system can record the maintenance history and performance data of bending machines. Through predictive analysis, potential machine failures can be foreseen in advance, allowing for preventative maintenance to be scheduled, reducing downtime, and improving production continuity.

Document management and traceability:

The document management function in the MES system can save all related production documents, including process parameters, operation manuals, and quality records. This not only helps standardize the production process but also provides necessary information support when it is necessary to trace the origin and production process of products.

Human-machine collaboration:

The MES system can also improve the work efficiency of bending machine operators. Operators can receive production tasks through the MES system and understand detailed process requirements and operation guidelines, ensuring accuracy and efficiency in operations.

If your company is also in the sheet metal industry and has plans to implement an MES system soon, to manage scheduling, production processes, materials, quality, equipment, and other aspects with precision, please feel free to contact us!