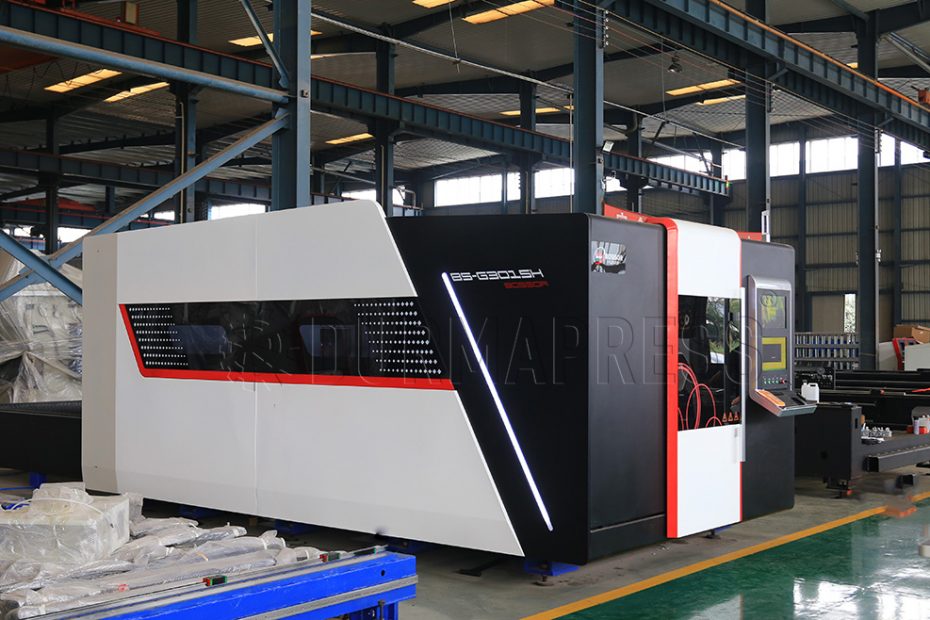

Durmapress high power fiber laser cutting machine is to use the fiber laser independently developed by the company to output high energy density laser beam,

and focus on the surface of the workpiece, so that the workpiece is superfine focus spot irradiation area instantaneous melting and gasification,

through the NUMERICAL control mechanical system to move the spot irradiation position to achieve automatic cutting.

It is a set of advanced fiber laser technology, numerical control technology, precision machinery technology in one of the high-tech equipment

high power fiber laser cutting machine Product features:

Laser cutting technology is a high production efficiency, strong productivity technology. Tube laser cutting machine has four advantages.

1, high cutting precision, and high dimensional precision incision smooth and clean, no burr, little material loss;

2, laser cutting of the heat affected zone is very small, almost no thermal deformation, no oxidation can make high-quality,

more consistent parts, especially conducive to the subsequent automatic welding;

3, high cutting efficiency, can achieve mass production.

All operations of laser cutting can be unified into the same unit as a continuous operation process,

greatly reducing logistics time. The standard pipe length is 6 meters, using the traditional processing method requires very heavy clamping,

and laser processing can be very simple to complete several meters of pipe clamping positioning, which makes the batch processing possible.