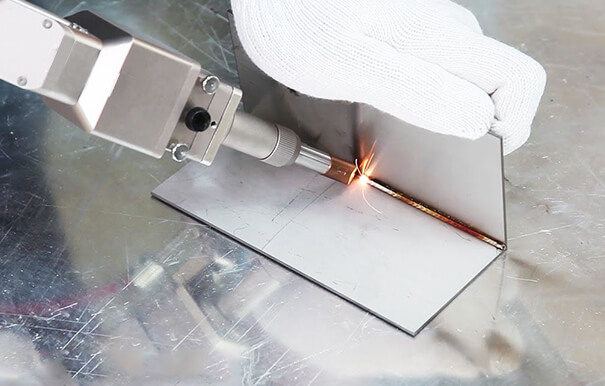

Under the trend of intelligent upgrading of the global manufacturing industry, the metal processing industry is undergoing a revolution in welding technology. DURMAPRESS handheld laser welding machine has become the first choice of more and more companies with its latest fiber laser technology, innovative swing welding joints and easy operation. Compared with traditional welding methods, handheld laser welding machines not only improve welding efficiency, but also significantly reduce operating costs and technical barriers. This article will deeply analyze the core differences between handheld laser welding machines and traditional welding to help companies understand the practical application value of this cutting-edge technology.

Welding efficiency revolution: double breakthrough in speed and precision

1.Comparison of actual operation speed

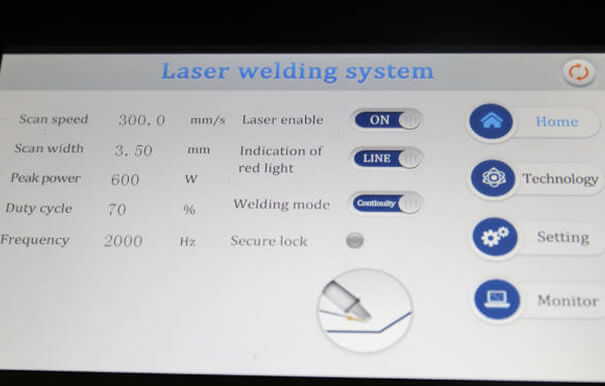

Traditional welding methods, such as TIG (argon arc welding) and MIG (gas shielded welding), have certain limitations in welding speed, especially when welding thinner metal materials, which requires frequent adjustments in current, voltage and welding angle. The DURMAPRESS handheld laser welding machine can achieve faster fusion speed through a high-energy-density fiber laser beam.

TIG welding: The welding speed of 3mm stainless steel is about 0.8m/min, and the tungsten electrode needs to be replaced continuously.

DURMAPRESS laser welding:Standard mode: 3.2m/min (straight welding). Swing mode: 2.5m/min (wider welds achieved through patented swing head). Zero consumables design: 8 hours of continuous operation without the need to replace consumables.Case: After a metal manufacturing company introduced DURMAPRESS equipment, the welding time of stainless steel door frames was shortened from 22 minutes per piece to 6 minutes, and the welding efficiency increased by 3 times.

2.Adaptability to complex working conditions

DURMAPRESS handheld laser welding machine has a wider range of material compatibility and can adapt to different welding needs, such as: Ultra-thin metal welding: 0.8mm galvanized steel plate welding achieves zero perforation, while traditional welding easily leads to high scrap rate. Small space operation: 30° bending welding head can achieve welding at complex angles. Multi-material compatibility: Suitable for stainless steel, carbon steel, aluminum alloy, copper and a variety of dissimilar metal combination welding.

Welding efficiency revolution: double breakthrough in speed and precision

1.No consumables required, reducing long-term operating costs

Traditional welding requires consumables such as welding wire, flux, and shielding gas, which are costly in the long run. In contrast, the DURMAPRESS handheld laser welding machine uses a fiber laser beam for welding without any additional consumables.TIG welding: Annual consumables cost accounts for about 30% of the total equipment cost. DURMAPRESS laser welding: No welding wire or shielding gas is required, which reduces long-term operating costs.

2.Reduced labor costs

DURMAPRESS equipment uses an intelligent guidance system, which allows new workers to quickly master welding technology without long-term training. Traditional welding requires certified welders, long training cycles, and high labor costs. DURMAPRESS laser welding: 2 days of training to master the operation, improve production flexibility.

Improved welding quality and reliability

1.Higher welding strength

Laser welding can form a narrower heat-affected zone, reduce metal deformation, and improve welding strength and fatigue resistance. The tensile strength of DURMAPRESS laser welding can reach 658MPa, and the fatigue life is increased by 3 times. Traditional welding has a large heat-affected zone and limited weld strength.

2.Surface treatment is easier

Laser welding can directly achieve high-quality smooth welds, reducing the subsequent grinding and polishing process.Case: After a home appliance manufacturer adopted the DURMAPRESS equipment, it eliminated the post-weld grinding process and reduced the unit cost by 15%.

Analysis of DURMAPRESS technical advantages

1.Independently developed swing welding technology

The DURMAPRESS handheld laser welding machine is equipped with the world's first oscillating welding joint. Compared with traditional laser welding, it can provide wider welds, more uniform welding effects, and effectively reduce welding porosity. Sine oscillation mode: suitable for thin metal welding to improve joint strength. Spiral oscillation mode: optimize thick plate welding and reduce weld cracks.

2.Applicable to welding needs of multiple industries

DURMAPRESS handheld laser welding machines are widely used in many industries, including: Automobile manufacturing: welding of body structure parts to improve weld strength. Home appliance manufacturing: welding of thin-walled stainless steel parts to improve product aesthetics. Building metal structures: welding of galvanized steel to reduce subsequent processing costs.

Safety and environmental advantages

1.Higher security

DURMAPRESS equipment uses low-voltage control system and intelligent temperature monitoring to ensure safe operation. Low energy consumption design: lower operating power, reducing electricity consumption. No arc hazard: There is no strong arc during laser welding, which is more friendly to operators.

2.A more environmentally friendly welding method

Compared with traditional welding, the DURMAPRESS handheld laser welding machine produces 92% less smoke and dust, which is more in line with the environmental protection requirements of modern factories.

conclusion

From the above comparison, we can see that the DURMAPRESS handheld laser welding machine has excellent performance in welding efficiency, cost control, weld quality, safety, etc., and is suitable for a variety of industry applications. High efficiency: fast welding speed, improved production efficiency. Low cost: no consumables, reducing long-term expenses. High quality: beautiful welds, reducing subsequent processing. Easy to operate: intelligent guidance, novices can also quickly get started. Safe and environmentally friendly: no arc, low smoke, more in line with international environmental standards. If your company is looking for a more efficient, economical and environmentally friendly welding solution, the DURMAPRESS handheld laser welding machine is undoubtedly your best choice.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)

-300x169.jpg)