Do you know the advantages and disadvantages of handheld laser welding machine? The new air-cooled laser welding machine is more convenient

Do you know the advantages and disadvantages of hand-held laser welding machines?

1. Advantages:

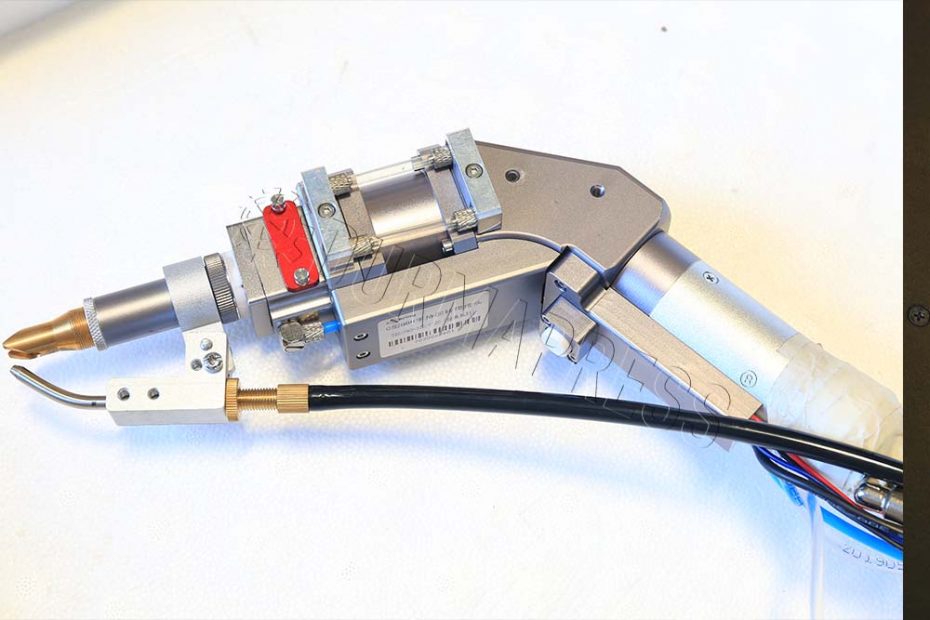

High quality laser beam, fast welding speed, weld firm and beautiful, to provide users with welding solutions. High safety, welding head is only useful when contacting metal, touch switch has temperature sensing function.

Hand-held water-cooled welding gun, ergonomic design, easy to move, longer welding interval, can complete the welding of any part of the workpiece. The electro-optical conversion efficiency is high, the energy consumption is low, the operation is simple and easy to learn, do not need professional welding master, ordinary workers can go on duty after a short time of exercise. Long-term application can greatly save the processing cost.

Hand-held laser welding machine has the advantages of small thermal influence, not easy to deformation, blackening, no trace, large welding depth, full melting, firm and reliable. Hand-held laser welding machine can complete welding from any Angle, can weld all kinds of welds disorderly workpiece and irregular shape of large workpiece. End welding of any viewpoint.

2. Disadvantages:

The hand-held laser welding machine requires the user to hold it. Long running will lead to fatigue, is not conducive to the welding of large original parts, the application scale is severely restricted.