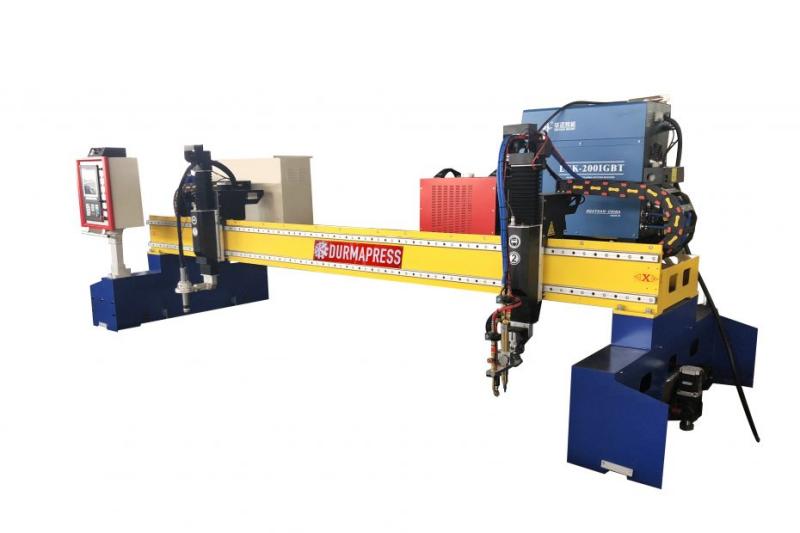

Gantry Type CNC Plasma Cutter Equipment Structure Features

The main girder features transverse and longitudinal guideways made of high-strength aluminum alloy die casting, ensuring overall stability. It is lightweight, resistant to deformation, aesthetically pleasing, and facilitates on-site movement and cutting, thereby enhancing efficiency. The bottom plate, constructed from 10mm aluminum alloy and CNC machined for precision, ensures prolonged service life. Oxygen and acetylene pipes integrated into the crossbeam provide convenience and safety without requiring external air pipe connections. The longitudinal guide rail includes a fixed slot for easy rail fixation.

Gantry Type CNC Plasma Cutter Chassis Side Panel Features

The chassis design incorporates a new combined structure that allows for the separation and reassembly of the cross arm, main console, and mechanical and numerical control components. The plug plate and cabinet are separable, facilitating maintenance and loading. Fan cooling is implemented to regulate internal cabinet temperature effectively. The plug board features a 4-core plasma interface for arc starting and pressure detection, with a backup interface available if plasma is not selected. An offline switch enhances efficiency by facilitating the cutting gun to find the benchmark, while an emergency stop switch ensures safety. The equipment is designed with a red background color for easy visibility.

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)