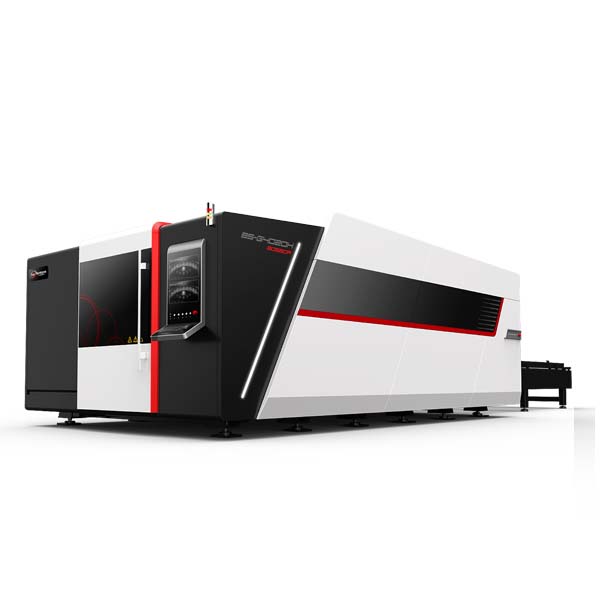

Fiber Laser Cutter-Full Covered Exchange Table

General Features

Full Covered Fiber Laser Cutting Machine with Exchange Table 3000W 4000W 6000W 10000W Advantages :

1. The entire fiber laser cutting adopts a large enveloping enclosed cutting process to provide a good operating environment;

2. The whole process of industrial camera tracking and monitoring without blind spots, to maximize the realization of the entire intelligent operation of the laser equipment

3. Imported servo motor and precise guiding transmission mechanism are adopted, and the cutting precision is high;

4. Use professional laser nesting software to design various parts for immediate processing at will;

5. The service life of fiber laser device and key components can reach 100,000 hours, and the laser and gun body are maintenance-free;

6. The product is easy to operate and maintain, comes with various cutting technology packages, and automatically transfers and uses different plates

Why Choose BS3015H

Fiber laser cutting Safe and beautiful design:

- Fully enclosed protective cover, in line with European safety standards;

- High machining accuracy:

- Equipped with high-torque servo motor and high-precision imported reducer, with high efficiency and good dynamic characteristics;

Good dynamics and cutting ability: - The high-rigidity welded body adopts aviation aluminum die-casting gantry, which improves the strength and weight of the gantry, and has good stability and durability;

- Easy to operate and intelligent:

- The professional digital control system developed by South Korea's MP company has realized the Hans digital control system with good performance, high reliability and easy operation.

- Low operating cost:

- Precise control to ensure low auxiliary gas consumption to ensure low operating costs. Three auxiliary gases can be freely selected by customers

HIGH PRICISION , HIGH SPEED

Intelligent Dual Drive

Gantry is adopted with dual servo motor drive system, synchronous dual drive, effectively ensure the high speed, precision and stability of the operation of the machine;

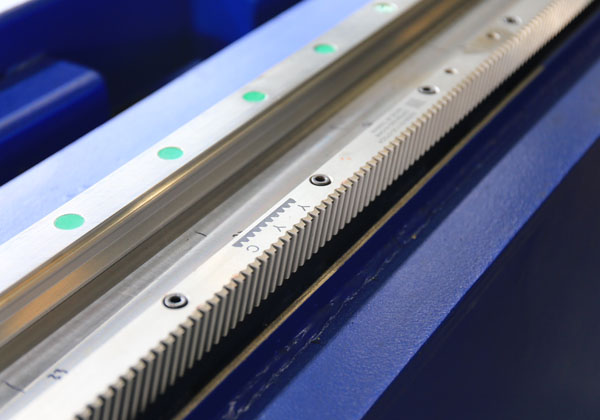

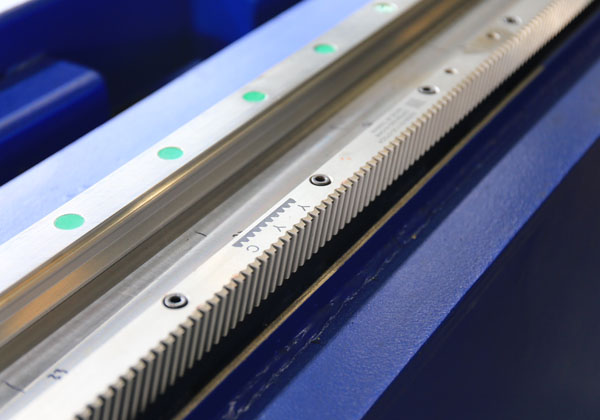

Imported Transmission Parts

Choosing high-end Alpha brand can ensure the high-speed cutting accuracy of the equipment for a long time.

Integrated Gas Path

Advanced integrated gas circuit control system, accessing different auxiliary gases, flexible selection, automatic switching, efficient.

Laser Cutting Head

Light Cutter 2.0

Whether for flatbed or angled cutting:

The LightCutter cutting head is the ideal solution for efficient and economical laser cutting in the medium power range up to 6 kW. The cutting optics are characterized by a high cut quality for all metals up to 16 mm thick - in particular structural steel, stainless steel and aluminum.

Fiber Laser Cutting Generator

IPG Laser Source

| 1000W - 4 kW average power range |

| Record wall-plug efficiency |

| Excellent reliability |

| Excellent single mode beam quality |

| Negligible beam pointing |

| Stable beam quality in full power range |

| Direct modulation in kHz range |

| Very low cost |

Reducer

Yaskawa Reducer

It has the characteristics of economy and practicality, high cost performance, high precision, good rigidity, large carrying capacity, high efficiency, long life, light and small size, beautiful appearance, convenient installation, accurate positioning and so on. Suitable for AC servo motors, DC servo motors, stepping motors, hydraulic motors to increase and decrease the transmission speed. Suitable for connection of drive products manufactured by any manufacturer in the world

In the application of servo control, it exerts good servo rigidity effect, accurate positioning control, and has the characteristics of low and medium backlash, high efficiency, high input speed, high input torque, smooth operation, and low noise on the operating platform. Small appearance and structure design

Rear

YYC Gear From Taiwan

To meet the needs of mechanical equipment, YYC provides racks and pinions with different modules, which can completely replace linear transmission products such as ball screws, cylinders, and linear motors, and have an excellent cost performance.

OTHER COMPONENTS

TECHNICAL PARAMETERS

| No. | Type | BS3015H | BS4020H | BS6020H | BS6025H | G8020D | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Machining area (Length *width) | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm | 8000*2000mm | ||||

| 2 | X-axis stroke | 1525mm | 4020mm | 6050mm | 6050mm | 8020mm | ||||

| 3 | Y-axis stroke | 3005mm | 2020mm | 2050mm | 2550mm | 2020mm | ||||

| 4 | Z-axis stroke | 150mm | 120mm | 350mm | 350mm | 150mm | ||||

| 5 | Positioning precision of X/Y axis | ±0.02mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ||||

| 6 | Repetitive positioning precision of X/Y axis | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ||||

| 7 | Maximum speed | 140m/min | 120m/min | 140m/min | 140m/min | 100m/min | ||||

| 8 | Maximum Acceleration speed | 1.5G | 1.5G | 1.5G | 1.5G | 1.5G | ||||

| 9 | Tool weight | 8500KGS | 3500KGS | 12000KGS | 12000KGS | 8000KGS | ||||

| 10 | Maximum load of workbench | 1000KGS | 2000KGS | 3000KGS | 3000KGS | 2000KGS | ||||

| 11 | Laser Power | 1000W/1500W/2000W/3000W/4000W/6000W/8000W | ||||||||

| 12 | Dimension ( Length * Width* Height) | 9800*2350*2000mm | 10100*3600*2400mm | 15400*4500*2600mm | 15400*4500*2600mm | 10400*3600*2300mm | ||||

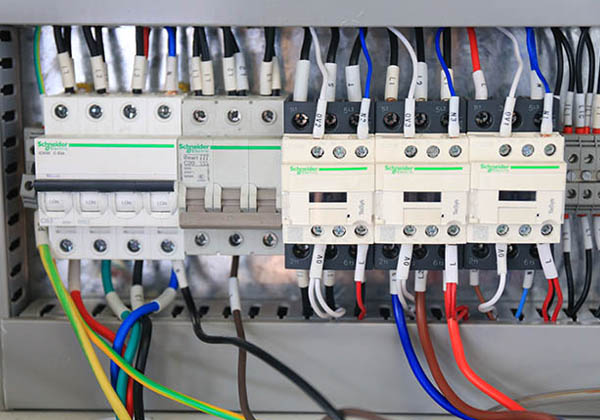

| 13 | Number of Phases | 3 | 3 | 3 | 3 | 3 | ||||

| 14 | Rated voltage of power source | 380V | 380V | 380V | 380V | 380V | ||||

| 15 | Frequency | 50HZ | 50HZ | 50HZ | 50HZ | 50HZ | ||||

| 16 | Protection rating of main power | IP54 | IP54 | IP54 | IP54 | IP54 | ||||