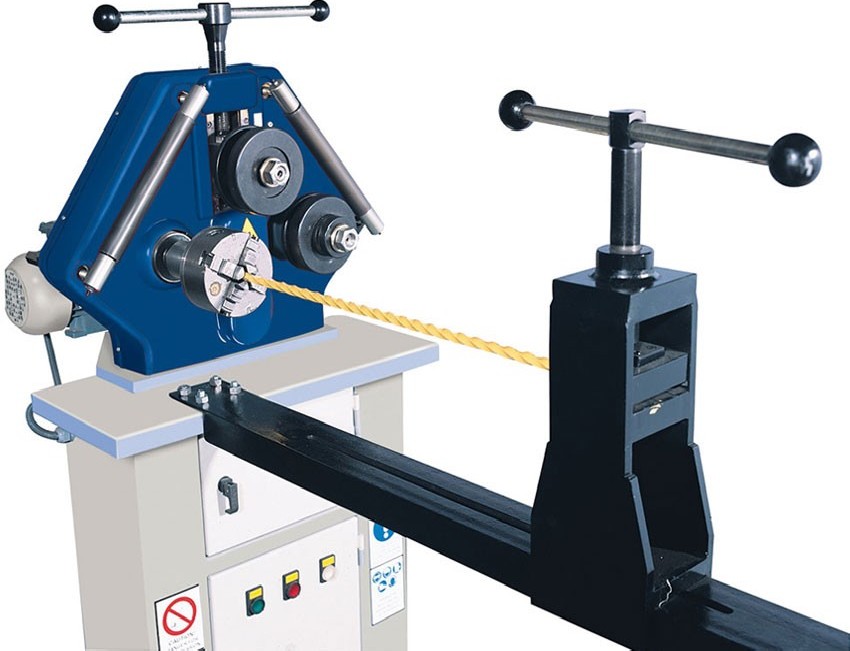

Working principle of four-roller profile bending machine: Volume of arc mode under profile bending machine,

the machine of two side roll roll, can also be three or four work roll roll, the roll fixed position,

two side roll around because of the rotary center for arc lifting move, hydraulic control, the displacement of the liquid crystal display,

is helpful to control profile forming process, high on both sides of the roller device, to ensure the rolling quality of asymmetrical section.

Application: it is the most advanced profile forming equipment at home and abroad, widely used in petroleum,

chemical industry, steel structure, machinery manufacturing and other industries of the production of various garden flange.

Four roller profile bending machine equipment features: can be one feeding material to complete the pre-bending of profiles,

rolling round and round calibration process; Advanced structure, full function, according to the user's use of standing or lying.

Four roller profile bending machine introduction: divided into flat bending and vertical bending two, it is bending flat steel, square steel,

round steel, Angle steel, I section steel, H section steel, square tube, rectangular tube, round tube and other profiles of the latest machine.

Can be customized according to user requirements of different molds. All four rollers are active rollers driven by four independent hydraulic motors.

Rolling speed, high efficiency.