Introduction to Fiber Laser Cutting Kerf

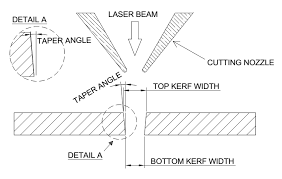

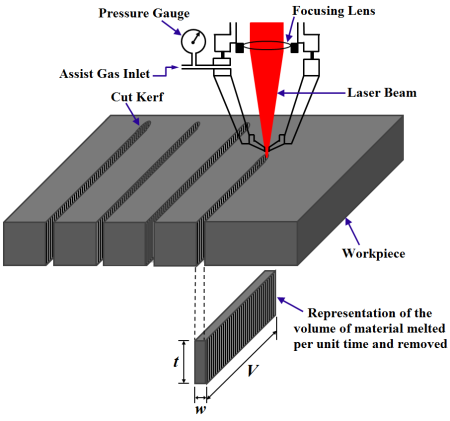

Fiber laser cutting kerf refers to the width of material removed by the laser beam during the cutting process. It plays an important role in determining the accuracy of the cut and the overall quality of the finished part. Understanding and controlling the kerf is essential to achieving the desired cutting results and optimizing material usage.In fiber laser cutting, various factors influence the width and properties of the kerf, including laser power, cutting speed, material properties, and assist gas. By adjusting these parameters, operators can optimize the kerf to meet specific cutting requirements and achieve desired results.Additionally, advances in fiber laser technology have led to the development of advanced cutting systems with enhanced kerf control capabilities. Modern laser cutting software allows you to precisely adjust kerf width based on material type, thickness, and desired cut quality.

Key factors affecting laser cutting Kerf

Fiber laser cutting kerf refers to the width of material removed by the laser beam during the cutting process. It plays an important role in determining the accuracy of the cut and the overall quality of the finished part. Understanding and controlling the kerf is essential to achieving the desired cutting results and optimizing material usage.In fiber laser cutting, various factors influence the width and properties of the kerf, including laser power, cutting speed, material properties, and assist gas. By adjusting these parameters, operators can optimize the kerf to meet specific cutting requirements and achieve desired results.Additionally, advances in fiber laser technology have led to the development of advanced cutting systems with enhanced kerf control capabilities. Modern laser cutting software allows you to precisely adjust kerf width based on material type, thickness, and desired cut quality.

Laser Power and Energy Density

Laser power and energy density are two important parameters that affect the Kerf of laser cutting. The higher the laser power and the higher the energy density, the greater the thermal influence of the laser beam on the material, which leads to a wider cutting gap (Kerf). Appropriate increase in laser power and energy density can speed up the cutting speed, but at the same time will also increase the heat affected zone, making the roughness of the cutting edge increase.

Cutting speed

Cutting speed is also one of the key factors affecting the Kerf of laser cutting. For a given laser power and energy density, cutting speeds that are too fast result in less time for the laser beam to thermally affect the material, resulting in a narrower cutting gap (Kerf). However, too fast a cutting speed may also lead to incomplete cutting or rough cutting edges. Therefore, it is necessary to select the appropriate cutting speed according to the material properties and laser power in actual processing.

Material Characteristics

Cutting speed is also one of the key factors affecting the Kerf of laser cutting. For a given laser power and energy density, cutting speeds that are too fast result in less time for the laser beam to thermally affect the Material properties such as thermal conductivity, melting point, density, etc. also have an important influence on laser cutting Kerf. For example, materials with high thermal conductivity tend to lose heat during the laser cutting process, making the cutting Kerf narrower; while materials with high melting point require higher laser power and energy density to realize complete cutting.

Auxiliary gas

In the laser cutting process, the use of auxiliary gases (such as oxygen, nitrogen, etc.) also has a certain impact on the cutting gap (Kerf). Auxiliary gases can help to remove molten material and oxides during the cutting process, improving cutting quality and efficiency. At the same time, the type and flow rate of the auxiliary gas also affects the width and shape of the cutting gap (Kerf). For example, using oxygen as an auxiliary gas speeds up the cutting speed but increases the heat-affected zone, while using nitrogen reduces the heat-affected zone but decreases the cutting speed.

Focal length and spot size

The focal length and spot size of the laser beam are also important factors in laser cutting Kerf. Focal length determines the degree of focus of the laser beam on the surface of the material, the longer the focal length, the larger the spot; and the spot size directly affects the thermal impact of the laser beam on the material range. Appropriate adjustment of the focal length and spot size can optimize the cutting effect and improve processing efficiency.

Summarize

Optimizing the kerf in a laser cutting process involves multiple levels of adjustment. At the machine level, the laser path can be offset to cut slightly beyond a specified line, compensating for material removal and preserving the dimensions of the original design. Designers can also manually adjust the design by adding or subtracting the width of the kerf from the component dimensions in the drawing to account for the kerf in the drawing. In addition, modern laser cutting software, such as Lightburn, offers kerf width adjustments that allow the user to set the kerf width based on material, power and thickness. These software adjustments ensure that precise cutting paths are automatically generated in conjunction with the specified kerf settings.

Effect of laser cutting kerf on processing results

Laser parameter adjustment

Laser power, cutting speed and focal length are the main laser parameters that affect the Kerf width. By adjusting these parameters, the Kerf width can be controlled and optimized.Different materials require different laser parameter settings. The best combination of laser parameters can be found through experimentation and data analysis.

Auxiliary gas optimization

Auxiliary gases play a role in cooling, combustion and blowing during the laser cutting process. Optimizing parameters such as the type, flow rate and pressure of the auxiliary gas can affect the Kerf width and cut quality.Choosing the right auxiliary gas and parameter settings can improve cutting efficiency and precision while reducing material waste.

Equipment Maintenance and Care

The performance of laser cutting equipment has a significant impact on Kerf width. Regular maintenance and servicing of the equipment to ensure that it is in optimum working condition can improve cutting accuracy and efficiency.Maintenance and servicing includes cleaning lenses, replacing wear parts, and calibrating equipment.

Exploration of new materials and processes

With the development of material science and process technology, new types of materials and processes continue to emerge. Exploring the application of these new materials and processes in laser cutting can further optimize Kerf width and processing results.For example, the use of thinner materials and the development of new cutting processes can reduce Kerf width and improve processing efficiency.

Industry case studies

Laser cutting kerf is widely used in automotive manufacturing, aerospace, electronics, and other fields. By analyzing actual cases in these industries, it is possible to understand the specific impact and optimization strategies of laser cutting Kerf in these fields.For example, in automotive manufacturing, optimizing laser cutting parameters can reduce the Kerf width of body parts and improve material utilization and processing efficiency; in the aerospace field, exploring new materials and processes can improve cutting accuracy and reduce costs.

Development trend

With the continuous development and innovation of laser technology, laser cutting technology is developing in the direction of high precision, high efficiency and low cost. In the future, with the continuous advancement of intelligent manufacturing, laser cutting technology will become more intelligent and automated, which will lead to more accurate and efficient processing. However, there are still some technical challenges in the development of laser cutting technology, such as how to further reduce the width of the slit and improve cutting precision and efficiency. Nevertheless, these challenges also provide opportunities for the development of laser cutting technology. Through continuous research and innovation, we can overcome these challenges and take laser cutting technology to the next level. This will serve for better quality and more efficient processing and promote the progress and development of the entire manufacturing industry.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.