substract

Laser cutting machines play a very important role in modern production, especially in manufacturing and industrial production, significantly improving cutting efficiency. This paper focuses on the importance of laser cutting machines in production, with a specific focus on four types: 1000W, 1500W, 2000W, 2500W , all powered by a medium power continuous fiber laser.

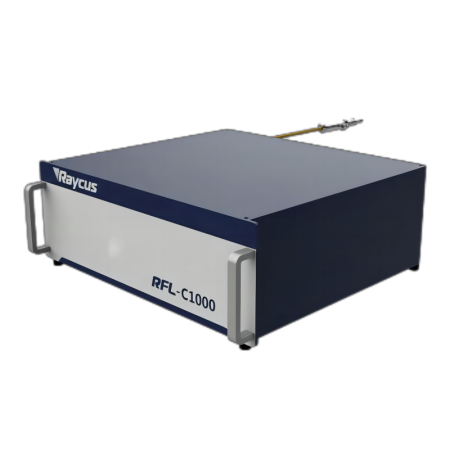

1000W Fiber Laser Cutting Machine

Cutting thickness

Cutting thickness is a key parameter that determines which materials can be cut and processed efficiently. For cutting machines, the range of application is often limited by the thickness of the material. In general, the cutting thickness is suitable for thin to medium-thick materials, which usually means that the material is between a few millimeters and about 6 mm thick.

It is in this thickness range that cutting equipment is able to deliver optimum performance and efficiency. Thinner materials tend to be easier to cut because they don't require much force or energy to penetrate.

Power Consumption Level

The degree of power consumption of a 1000w laser cutter depends largely on its efficiency and length of use. Theoretically, if a laser cutter runs continuously at maximum power for an hour, it will consume 1000 watt-hours (Wh) of electricity, or 1 kWh. However, in practice, the power consumption of a laser cutting machine may be affected by a variety of factors, such as the design of the equipment, the manufacturing process, the type of material, the cutting speed and so on.

Product Features

- Efficient Cutting: 1000W laser cutting machine adopts high power laser beam, which can cut various materials quickly and precisely. The laser cutting speed and high efficiency can greatly improve productivity.

- High precision: laser cutting has very high precision and can cut very fine lines and shapes. This is very important for applications that require high precision cutting, such as automotive parts, electronic components and other fields.

- Wide range of application: 1000W laser cutting machine is suitable for cutting various materials, including metal, non-metal, organic and inorganic materials. Therefore, it can meet the needs of different industries, such as machinery manufacturing, automobile manufacturing, aerospace, building decoration and other fields.

- Low energy consumption: Compared with traditional cutting methods, laser cutting machine consumes less energy. Because of the high concentrated energy of the laser beam, the heat-affected zone is small when cutting, and there is less material waste, thus reducing energy consumption and operating costs.

- Easy operation: 1000W laser cutting machine adopts advanced CNC control system, which can realize automatic operation, easy to operate and easy to master. Meanwhile, it is also compatible with various software, which is convenient for users to program and control.

- Suitable for small and medium-sized processing enterprises: 1000W laser cutting machine is suitable for small and medium-sized processing enterprises to use, because it has high cost-effective, can meet the production needs of these enterprises, and at the same time will not cause excessive economic pressure.

Applications

- Thin plate cutting:

The 1000W laser cutting machine shows excellent performance in thin plate cutting. It can cut a wide range of metal materials, such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy and so on. As the laser cutting is characterized by high precision, high speed, narrow kerf and minimal heat-affected zone, it makes it a significant advantage in the field of thin plate cutting. The laser cutting head does not come into contact with the material surface, thus avoiding scratches on the workpiece. In addition, the processing flexibility of the laser cutting machine is good, which can be adapted to the needs of thin plate cutting of different thicknesses, and the cutting surface is smooth and burr-free, and the local deformation of the workpiece is extremely small, with no mechanical deformation.

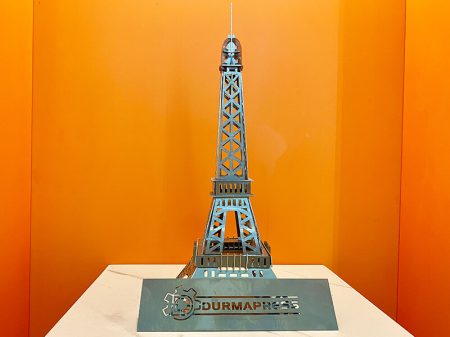

- Fine pattern processing:

In addition to thin plate cutting, a 1000W laser cutting machine is also widely used in the field of fine pattern processing. Due to its high precision and high speed, the laser cutting machine can easily cut various complex patterns and shapes, such as text, patterns, logos and so on. This makes it have a wide range of application prospects in the field of handicrafts, advertising, decoration and so on. At the same time, the laser cutting machine can also cut tubes and other profiles, further expanding its application in the field of fine pattern processing.

1500W Fiber Laser Cutting Machine

Cutting Thickness

Suitable for medium-thickness materials, usually between 5 mm and 8 mm, it can easily cope with the cutting needs of these materials. There is a slight increase in power consumption compared to the 1000W model, but this extra power provides faster and more efficient cutting speeds, as well as enhanced ability to handle thicker materials. This model is an ideal choice for both small workshops and medium-sized processors, adding more flexibility and efficiency to your production line.

Product Features

Compared with 1000w laser cutting machine, 1500w laser cutting machine has the following features

- High efficiency: the cutting speed of the laser cutting machine is very fast, which greatly improves the productivity. For example, the speed of 1500w laser cutting machine can reach 40mm/s when cutting 1mm stainless steel, which makes the processing volume per unit time increase greatly.

- High precision: the laser cutting machine has a very high cutting precision, which can realize high-quality material processing. At the same time, the laser cutting process has a small heat-affected zone, which can ensure that the cutting edges of the workpiece are smooth and flat, reducing the workload of subsequent processing.

- Wide applicability: the laser cutting machine is suitable for cutting all kinds of metal plates, including stainless steel, carbon steel, aluminum plate, copper plate and many other materials. In addition, the laser cutting machine can also be adjusted according to the thickness of different materials, to achieve both thick and thin cutting.

Applications

Cutting of medium and thick plate materials, usually between 5 mm and 8 mm, and cutting of metal tube materials are the main applications. The industry is mainly for small parts, such as in the electronics industry for cutting metal cases, heat sinks and other parts.

2000W Fiber Laser Cutting Machine

Cutting Thickness

Designed for thicker materials, approximately 8mm to 10mm thick.

Power Consumption

When comparing the power consumption level of 1500W laser cutting machine and 2000W laser cutting machine, we first need to understand the relationship between the power of the laser cutting machine and its power consumption. Power is the amount of electrical energy consumed by a device per unit of time and is usually measured in watts (W). Therefore, the higher the power, the more electricity the device theoretically consumes per unit of time.

By this logic, a 2000W laser cutter is higher in power than a 1500W laser cutter, so a 2000W laser cutter will theoretically consume more electrical energy under the same operating conditions. This is because it requires more energy to maintain a higher power output to accomplish the cutting task.

Product Features

First of all, its high power output makes the cutting process faster and more efficient. This powerful power ensures that the cutting process is completed in a short time, greatly improving productivity.

Secondly, laser cutting is characterized by high precision and quality. The precise control of the laser beam can realize accurate cutting, which makes the cutting edge smooth and neat without subsequent processing.

Applications

With its excellent performance and efficient working ability, the 2000w fiber optic cutting machine is ideal for cutting thick plates and stainless steel. This cutter is not only equipped with high-precision cutting technology, but also can easily cope with the needs of complex patterns and curve cutting. Whether it is a multi-angle or multi-layer cutting task, the 2000w fiber optic cutting machine can complete it with excellent stability and precision, ensuring the quality and aesthetics of the product. In addition, the cutting machine also has efficient working ability, can quickly complete the cutting task, improves production efficiency. In summary, the 2000w fiber optic cutting machine is an excellent choice for cutting thick plates, stainless steel, and complex patterns and curves.

2500W Fiber Laser Cutting Machine

Cutting Thickness

The thickness range of steel plates that can be cut by 2500W fiber laser cutting machine may vary depending on the specific brand, quality, application environment, speed and other factors. Generally speaking, the maximum thickness of carbon steel plate that can be cut by 2500W fiber laser cutting machine is about 12mm, while the maximum thickness of stainless steel plate is about 10mm. The above data is for reference only, if you need to know the cutting thickness of specific brands or models of 2500W fiber laser cutting machine, it is recommended to consult the technical specifications of the relevant equipment or equipment suppliers.

Power consumption

The 2500W fiber laser cutting machine consumes more power than the lower power models. This is due to the fact that higher power machines require more power to drive the laser generator, cooling system and other related components during operation. As the laser power increases, the efficiency and cutting ability of the machine improves, but this is also accompanied by higher energy consumption.

Specifically, high power laser cutting machines require more energy to generate and maintain a high power laser beam during the cutting process, which results in higher power consumption. In addition, high power equipment usually requires a more powerful cooling system to ensure stable operation of the equipment, which also increases energy consumption.

It is important to note that although high power devices consume more energy, they offer significant advantages in terms of efficiency, cut quality and speed.

Product Features

Extremely high cutting speed: the fiber laser cutting machine adopts the latest laser technology and high-precision cutting head design, which can achieve very high cutting speed and greatly improve productivity.

High stability: the fiber laser is compact, and small in size, with a fixed optical path and low energy consumption, making the cutting quality very stable. At the same time, the optical path is not restricted and the fiber transmission loss is small, which can greatly expand the processing range.

Low maintenance cost: Due to the use of fiber optic transmission, there is no need for reflector, which greatly reduces the maintenance cost. At the same time, no laser working gas, also saves a lot of maintenance costs.

Easy to operate: The equipment adopts a touch screen operation interface, which is feature-rich and easy to operate. At the same time, the equipment is equipped with ergonomically designed workbench and operating table, which makes loading and operating the machine easier and more comfortable.

Applications

The 2500w fiber laser cutting machine does play a great role in heavy industry, especially in aerospace and automotive manufacturing. With its high precision, high efficiency and high reliability, this kind of equipment is massively used in the cutting of steel plates.

Firstly, for the aerospace sector, the 2500w fiber laser cutting machine is able to provide precise cutting, which is essential for the manufacture of high-precision aerospace components. Aerospace components require extreme precision and strict quality control, as any small error can affect the performance and safety of the entire vehicle. This laser cutting machine is capable of cutting complex shapes in a short period of time, while ensuring smooth and neat cutting edges, greatly improving production efficiency and product quality.

Secondly, for the automobile manufacturing field, 2500w fiber laser cutting machine also plays an important role. With the rapid development of the automobile industry, the precision and quality requirements for automobile parts are getting higher and higher. This laser cutting machine can quickly and accurately cut steel plates of various shapes and sizes, providing high-quality parts for automobile manufacturing. Meanwhile, due to the small heat-affected zone generated during the laser cutting process, the deformation and stress of the material can be reduced, thus improving the stability and reliability of the products.

Highly automated and intelligent operation Fiber laser cutting machines can be networked with computers for intelligent processing control. This not only improves productivity, but also automates multiple work steps, reduces manual operation and lowers labor costs.

Energy saving and environmental protection: its photoelectric conversion efficiency is as high as about 30%, which is three times that of CO2 laser cutting machine, and the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machine, which is conducive to reducing the operating cost and maintenance cost.

Selection considerations

Material Thickness

When selecting a CNC machine, it is critical to consider material thickness. This is because different machines have different limits on the thickness of the material they can process. For thinner materials, you can choose a relatively lightweight machine, while for thicker materials, you will need to choose a heavy-duty machine that can withstand more pressure and shear. For example, if you regularly work with metal materials that are more than 10 millimeters thick, then you need to choose a machine with a powerful spindle and cutting capacity. It's also important to consider the rigidity and stability of the machine to ensure that no deformation or vibration occurs during the machining process.

Power Consumption

Power consumption is a factor that needs to be carefully considered when choosing a CNC machine. Power consumption not only affects the running cost of the machine, but also relates to the machine's energy efficiency and environmental friendliness. Generally speaking, machines with higher power offer more efficient cutting capabilities, but they also consume more electricity. Therefore, when selecting a machine tool, the relationship between power consumption and performance needs to be balanced according to actual machining needs and budget. In addition, consider choosing machines with energy-saving technologies, such as inverter-controlled spindles and servo systems, to reduce energy consumption and running costs.

Machine Size

Machine size is another important factor to consider when selecting a CNC machine. The size of the bed not only determines the machining range of the machine, but also affects the stability and accuracy of the machine. Larger bed sizes can handle larger workloads and allow for the installation of more tools and fixtures, resulting in more efficient machining. However, larger machines also require more space and infrastructure to support, so factors such as machining needs, site conditions and budget need to be considered when making a selection.

Budget

Budget is one of the most important considerations when choosing a CNC machine tool. The price of different models and configurations of machine tools varies greatly, ranging from tens of thousands to millions. Therefore, when choosing a machine tool, you need to develop a budget based on actual needs and uses, and choose the most cost-effective machine tool within the budget. At the same time, also be careful not to just the pursuit of low prices and ignore the performance and quality of the machine tool, otherwise it may bring unnecessary trouble and losses to the subsequent production and processing.

Summarize

In our guide to fiber laser cutting machine models, we have explored the features and applicability of different models from 1000W to 2500W. These machines offer diverse options for processors to find the model that best suits their needs based on factors such as material thickness, power consumption and budget. For small and medium-sized processing enterprises, the 1000W and 1500W models are good choices, featuring energy-saving, high efficiency and easy operation. For large-scale processing needs, the 2000W and 2500W models have faster cutting speeds and higher power outputs, accommodating thicker materials and more challenging cutting tasks.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)