DURMAPRESS factory specializes in producing high-end electro-hydraulic CNC Press Brake and fiber Laser Cutting Machines,Among them, laser cutting machine has many different series of products worthy of attention. This article introduces the company's products and tells you the precautions for metal cutting.

BS-D series fiber laser cutting machine

Desktop fiber laser cutting machine, the body is relatively compact and lightweight.The BS-D Series are our economical sheet metal fiber lasers designed for high-precision cutting applications and are ideal for small to medium-sized businesses. It features an open bed design with the option to add a full cover if desired.This machine is suitable for cutting carbon steel, stainless steel, galvanized steel, aluminum and other sheet metals.

BS-D Pro Series Fiber Laser Cutting Machine

Higher speeds and a sturdier bed design.The BS-D Pro Series is a high-volume fiber laser cutting machine that gives you precision cutting at high acceleration and speed for the best finish on a variety of materials and thicknesses.It will provide small and medium-sized enterprises with the ability to cut thin metal sheets such as carbon steel, stainless steel, galvanized steel, aluminum, etc.

BS-H series closed fiber laser cutting machine

Full coverage laser cutting machine, switching station improvement work.The BS-H Series is our fully enclosed dual-table industrial fiber laser cutting machine. It is designed with a range of features, such as a dual interchangeable table system, making it ideal for high-volume cutting. The machine features a CE-certified glass enclosure, providing safety when integrated into factory layouts or educational environments.This fiber laser cutting machine is suitable for cutting carbon steel, stainless steel, galvanized steel, aluminum, brass and other metal plates.

BS-G series tube sheet fiber laser cutting machine

The BS-G series are our open fiber lasers with rotary cutting and dual loading stations. This machine is designed for precision and high-volume cutting applications and can be used in a variety of applicationsThis metal processing laser is suitable for cutting metal sheets such as carbon steel, stainless steel, galvanized steel, aluminum and brass, as well as round, oval, square, rectangular and hexagonal tubes with a diameter of 20-200mm.

BS-E series closed tube sheet fiber laser cutting machine

The BS-E Series are our fully enclosed production fiber lasers with rotary cutting capabilities. Designed for high accuracy and long life, it is designed for high-volume applications.This metal processing laser is suitable for cutting metal sheets such as carbon steel, stainless steel, galvanized steel, aluminum and brass, as well as round, oval, square, rectangular and hexagonal tubes with a diameter of 20-200mm.

BS-T series pipe fiber laser cutting machine

The BS-E Series are our fully enclosed production fiber lasers with rotary cutting capabilities. Designed for high accuracy and long life, it is designed for high-volume applications.This metal processing laser is suitable for cutting metal sheets such as carbon steel, stainless steel, galvanized steel, aluminum and brass, as well as round, oval, square, rectangular and hexagonal tubes with a diameter of 20-200mm.

Information on cutting work in stainless steel, carbon steel, aluminum, copper

durmapress's laser cutting machines are mainly used to cut stainless steel, carbon steel, aluminum, and copper. Next, the detailed information of their cutting work will be introduced through icons to facilitate customers to find models that match their needs.

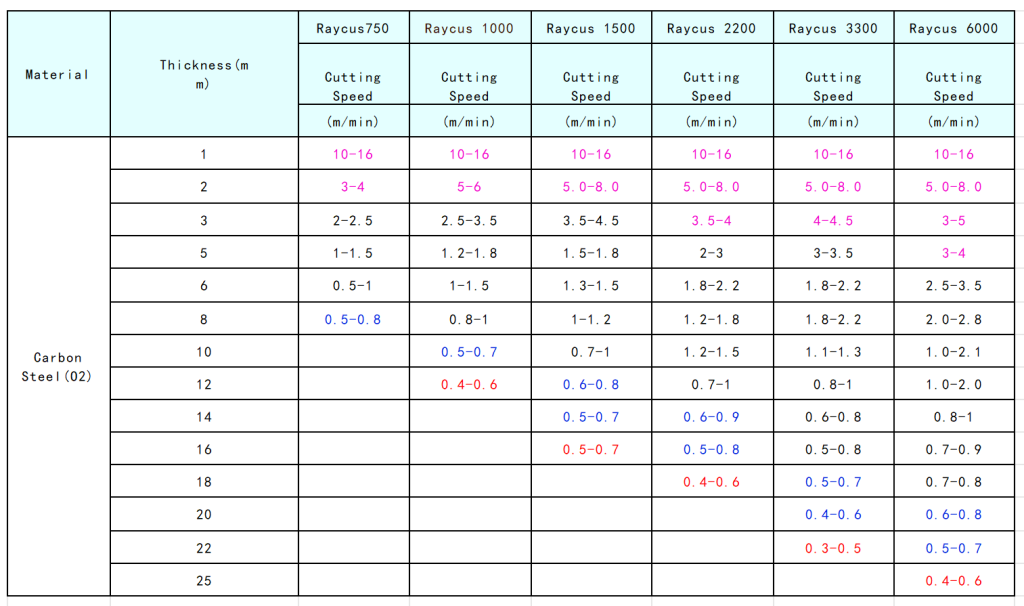

Carbon steel cutting information

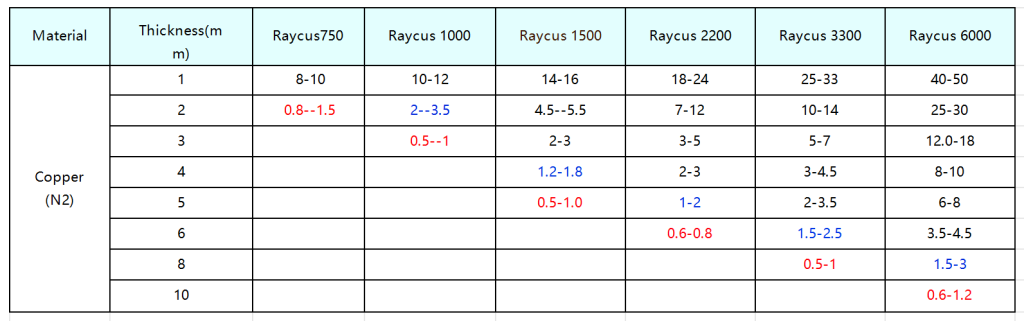

copper steel cutting information

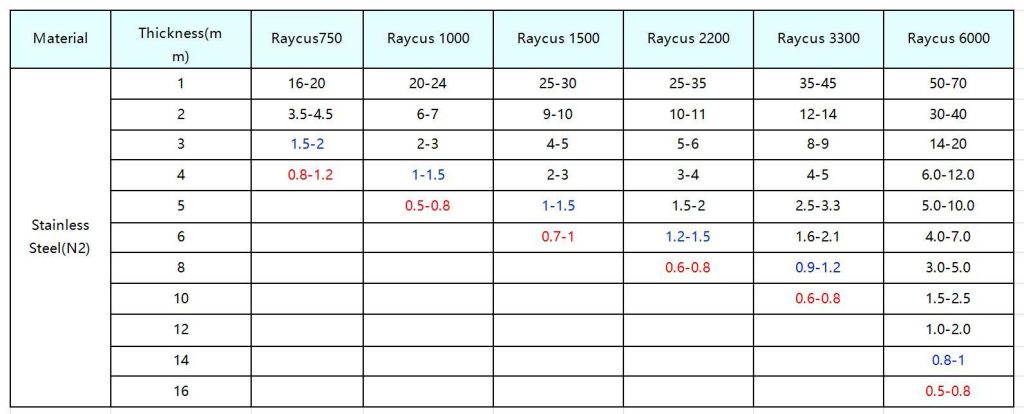

stainless steel cutting information

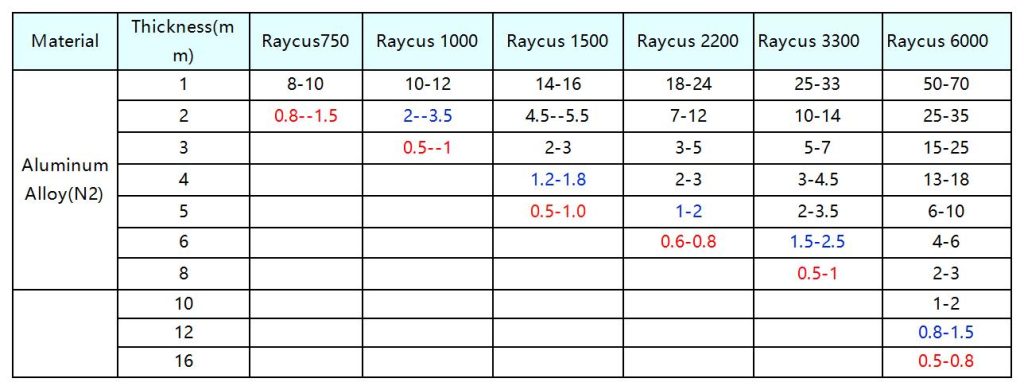

Aluminum Alloy cutting information

Fire prevention measures

No Smoking

Smoking is strictly prohibited in the cutting machine area, especially near oxygen bottles. This is because smoking may cause fires, and once a fire occurs, it will pose a serious threat to personnel and equipment. Therefore, to ensure the safety of the cutting machine area, we must strictly adhere to the no-smoking regulations.

The following points must be noted when using oxygen

1. Ensure that the oxygen bottle is safely fixed: The oxygen bottle will be vibrated during the cutting process. If the vibration is too large, the oxygen bottle may lose balance or even fall. Therefore, when using oxygen, be sure to secure it securely to the stand to prevent accidents.

2. Avoid contact between oxygen bottles and fire sources: Oxygen itself has combustion-supporting properties. If it comes into contact with fire sources, it may cause a fire. Therefore, when using oxygen, make sure the surrounding environment is clean and away from fire sources and flammable items.

3. Check the oxygen cylinder regularly: During long-term use, oxygen cylinders may suffer from wear, aging and other problems. In order to ensure the safety of oxygen cylinders, they must be inspected regularly and any problems found should be dealt with in a timely manner.

4. Master correct cutting skills: When using oxygen for cutting, you must master correct cutting skills to avoid accidents caused by high temperatures and sparks during the cutting process.

5. Equipped with necessary protective equipment: During cutting operations, operators should wear corresponding protective equipment, such as protective glasses, masks, gloves, etc., to prevent splashes generated during the cutting process from causing harm to the human body.

Laser cutting and human body

Skin damage

Problem: Direct contact with the laser beam may cause burns or tissue damage.

Safety advice: Avoid direct contact with the laser beam and wear appropriate protective clothing and gloves. Make sure the laser cutting area limits access to unauthorized personnel.

Smoke and gas

Problem: The fumes and gases produced during laser cutting can have harmful effects on the respiratory system.

Safety recommendations: Install an effective ventilation system in the laser cutting area to ensure that the generated smoke, dust and gas are discharged. Workers should wear appropriate respiratory protective equipment.

Fire risk

Problem: Laser cutting can cause fires, especially when the laser interacts with flammable materials.

Safety recommendations: Implement fire protection measures in laser cutting areas, including using fire-resistant materials, keeping work areas tidy, and ensuring fire extinguishers and other fire-fighting equipment are easily accessible and operable.

Radiation risk

Problem: Laser cutting may produce ultraviolet, infrared and other radiation, which may have adverse effects on human tissue.

Safety advice: Avoid prolonged exposure to laser radiation and use appropriate protective equipment, such as protective clothing suitable for laser cutting radiation.

respiratory protection

Install supporting dust removal device to ensure operation in a well-ventilated environment.

Use a mask, especially when cutting special metal materials, to prevent inhalation of harmful gases and dust.

Eye protection:Arrange the work site to reduce reflection or radiation of ultraviolet rays.

Wear dark-colored eye protection or goggles to protect your eyes from laser radiation.

Skin protection:Wear long-sleeved clothing and gloves to prevent the laser from shining directly on your skin and causing burns.

Do not touch the cut parts immediately, and wear gloves to prevent burns due to residual heat.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)