Why Traceless press brake toolings are becoming more and more popular with customers

Visión general

What is Traceless press brake tooling

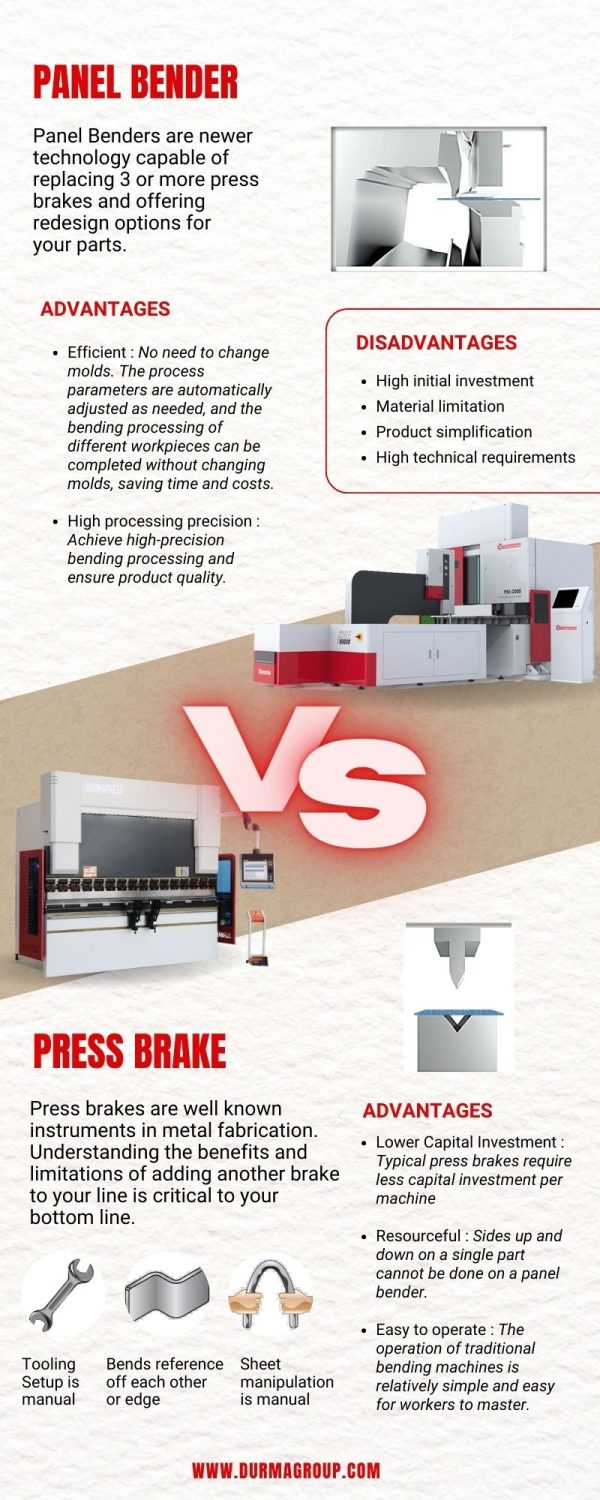

In today's highly competitive market environment, product quality has become the basis for enterprises. In order to meet consumers' high demands on product appearance and performance, many industries have set higher standards for tooling technology during the production process. In this context, the Traceless press brake tooling has emerged as a specially designed tooling designed to avoid producing marks or indentations on the surface of the workpiece. Such toolings play a vital role in industrial processing and production where high precision and appearance are required.

The non-marking die is a die with an innovative design concept, whose main feature is the ability to minimize damage to the surface of the workpiece during machining, guaranteeing the appearance and dimensional accuracy of the workpiece. This kind of tooling is made of special material and process, with good wear resistance, corrosion resistance and high strength to ensure that it can maintain stable working performance during long time use. Traceless press brake toolings are widely used in many industrial fields, such as automobile manufacturing, electronic products, home appliances, plastic products and so on. In these industries, the appearance and dimensional accuracy of the products are of paramount importance, so the use of Traceless press brake tooling production has become a key factor in improving product quality.

Specific types

Ball Traceless press brake tooling

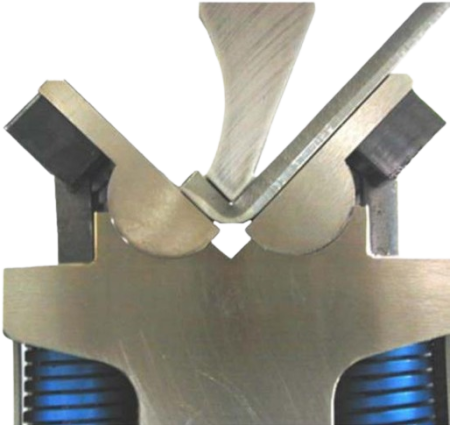

Ball Traceless press brake toolings play an important role in sheet metal bending processing. Their design is unique in that the workpiece comes into contact with a tungsten carbide mandrel on the lower die during the bending process, which rotates in the direction of sheet movement. This design allows the workpiece to change from traditional sliding friction to rolling friction when in contact with the lower die. This rolling friction dramatically reduces the possibility of indentation and abrasion on the surface of the workpiece caused by extrusion, effectively improving the appearance quality and machining accuracy of the product. However, although this tooling design can significantly reduce the indentation and abrasion, but in the bending process of soft plate, it is still difficult to completely avoid bending indentation, because there is still a certain amount of extrusion pressure between the lower die roller and the plate

Tension spring type Traceless press brake tooling

Unlike ball Traceless press brake tooling, tension spring Traceless press brake tooling are designed to take advantage of the mechanism by which the upper die presses the workpiece into the lower die body. In this type of die, the workpiece is in contact with the plane of the rotating flap, which rotates in the lower die body. There is no relative sliding of the workpiece against the rotating flap during the entire bending process, and the workpiece is in face contact with the rotating flap. This surface contact eliminates indentations and abrasions on the surface of the workpiece due to extrusion. Therefore, the spring-type Traceless press brake tooling effectively improves the appearance quality and processing accuracy of the workpiece, especially suitable for workpieces with high requirements on appearance.

Advantages of Traceless press brake toolings

Wide range of applications

Non-marking dies are known for their suitability for a wide range of materials, and are particularly good at working with materials such as soft metals and plastics. Soft metals, such as aluminum and copper, and materials that tend to leave marks, such as plastics, often face problems with marks and deformation in conventional tooling processing. However, Traceless press brake toolings are designed and manufactured with the characteristics of these materials in mind, using special processing techniques and materials that allow them to achieve excellent results when machining these materials.

In the aerospace industry, Traceless press brake toolings are widely used in the manufacture of aircraft and spacecraft parts. The need for aluminum alloys and lightweight structures common in aerospace materials makes the role of non-marking dies critical. They ensure that aircraft structural parts do not leave any marks during the bending process, guaranteeing the quality of the aircraft's appearance and performance.

In automotive manufacturing, Traceless press brake toolings are also indispensable tools. The manufacture of automotive parts requires a high level of appearance quality and precision, especially for aluminum alloy bodies and plastic interior parts. Traceless press brake toolings can ensure that these parts do not leave any marks during the bending and forming process, thus ensuring the appearance and quality of the car.

Traceless effect

Machining with Traceless press brake toolings can achieve a high degree of non-marking effect, i.e. no traces or marks will be left behind after the workpiece has been machined. This is crucial for industries that demand the highest quality of product appearance. Especially in the field of precision instruments, electronic products, etc., every small defect on the surface of the workpiece may affect the performance and appearance quality of the product. Therefore, the application of Traceless press brake toolings can ensure that the surface of the workpiece is smooth and flawless during processing, thus enhancing the overall quality and market competitiveness of the product. This non-marking effect not only makes the product appearance more attractive, but also makes the product more reliable and durable, in line with consumer demand and expectation for high quality products.

Durabilidad

The uniqueness of Traceless press brake toolings lies in the high abrasion resistance of the materials used to make them, a characteristic that gives them a long service life and has a profound impact on production efficiency and cost control.

toolings made from highly wear-resistant materials are hard and resistant to abrasion, so they can withstand higher pressures and more complex production environments during use. This means that Traceless press brake toolings can maintain stable productivity over a long period of time, without the need for frequent replacement due to rapid wear and tear. This undoubtedly saves on tooling replacement costs and production downtime for companies, and improves overall productivity.

In addition, the durability of Traceless press brake toolings also allows companies to better control product quality during the production process. Due to the long life of the toolings, the production is more stable, so the quality of the products is more reliable, which wins a good reputation and market competitiveness for the enterprise.

In addition, the durability of Traceless press brake toolings also brings greater flexibility for enterprises. During the production process, if there is a need to adjust the product design or production strategy, the Traceless press brake tooling can easily achieve this goal. Because the tooling itself is not easily worn out, it can be modified in a short period of time and then continue to be put into production. This flexibility allows companies to react quickly in the face of market changes, improving their market competitiveness.

Precision machining

Precision machining technology occupies a pivotal position in modern manufacturing industry, and Traceless press brake tooling design is the key link of precision machining. It realizes excellent processing of workpieces with a high degree of accuracy and consistency, whether in terms of bending angle, size or shape.

Traceless tooling design has a strong advantage in terms of bending angle. Generally speaking, it is difficult to control the bending angle accuracy of workpieces during processing, while precision tooling design can effectively solve this problem. Through precise calculation and fine design, the Traceless press brake tooling can ensure that the workpiece always maintains a consistent angle in the bending process, which greatly improves the processing accuracy.

Secondly, in terms of dimensions, Traceless press brake tooling design is also outstanding. Dimensional accuracy is an important measure of product quality in the manufacturing industry, and precision tooling design can achieve accurate control of the size of the workpiece. In the process of machining, the Traceless press brake toolings make the size of the workpiece always consistent through accurate size setting, which further improves the quality of the product.

Traceless toolings are better than ordinary toolings in terms of shape processing ability. In the manufacturing industry, the shape of workpieces is complex and diverse, which puts forward higher requirements for processing technology. And the Traceless press brake tooling design by virtue of its exquisite technology, can realize the precise processing of various complex shapes of workpieces. Whether it is a regular round, square, or irregular curved surfaces and grooves, the Traceless press brake toolings can easily cope with them and ensure the processing quality.

High Appearance Requirements

For products with high appearance requirements, such as home appliances and cell phones, Traceless press brake toolings can ensure that the surface of the workpiece is perfect and free of defects, ensuring that the appearance of the product meets the highest standards of quality. In today's competitive market environment, the appearance quality of products has become a key factor for major brands and companies to compete for market share. The competitive advantage of products with high appearance requirements, such as home appliances and cell phones, depends largely on the product's appearance design and innovation. Therefore, how to improve the appearance quality of products has become the focus of attention of many enterprises. The emergence of Traceless press brake tooling technology provides a perfect solution to this problem.

Traceless tooling, as the name suggests, is a special process and technology that makes the surface of the product workpiece smooth and perfect without any defects during the tooling manufacturing process. This tooling technology ensures that the appearance of the product is of the highest quality standard, making the product stand out in the market competition. The combination of control system and cad technology during production greatly enhances the exquisiteness of the appearance.

Difference with ordinary tooling

The difference between precision toolings and ordinary toolings is mainly reflected in the accuracy, drawing design and tolerance control.

Precision requirements

The key dimensions of precision toolings are usually very demanding, with no skew or deviation allowed. This means that when making a precision tooling, the skew and deviation must be minimized as much as possible.

Ordinary toolings are relatively loose in the requirements of key dimensions, allowing a certain degree of skew and tolerance. Tolerance bands can be fully utilized when making them to reduce the strict requirements on dimensions.

Drawing design

The drawing design of precision tooling needs to be more comprehensive, complete and accurate. Need to consider the size, location and processing mode of each part. Try to use inserts to reduce the impact of manual processing.

Drawings for general toolings are relatively simple and may not require excessive inserts and fine dimensional control. Hand machining techniques and processes may play a greater role in common toolings.

Tolerance Control

All parts of a precision tooling require tight design tolerances. Not only the working part of the cavity and core, but also the dimensions related to the mounting position of all inserts should be strictly limited, usually within plus or minus 0.005.

General tooling tolerance control is relatively loose, can be in the range of plus or minus 0.01 or greater tolerance control

How to choose according to the demand

Production Lot and Frequency

If you need to produce large quantities and require consistent productivity and quality, the durability and stability of a Traceless press brake tooling will be more suitable.For small batch production or sample making, you can consider normal toolings.

Cost Consideration

Traceless press brake toolings are generally more costly, but in some occasions with high demand for appearance and large production volume, cost can be saved by improving product competitiveness and reducing scrap rate.Ordinary toolings cost less and are suitable for some occasions with less strict requirements on appearance.

Technical Requirements

The manufacture and use of Traceless press brake toolings may require higher technical requirements, including processing technology, process control and other aspects.Ordinary toolings are relatively simple and have lower technical requirements.

Product Design and Market Positioning

The final choice depends on the product design and market positioning. If the product is positioned as high-end and high quality, then the Traceless press brake tooling can provide better appearance quality.If the product is positioned as a general consumer product or in a cost-sensitive market, ordinary toolings may be more suitable.

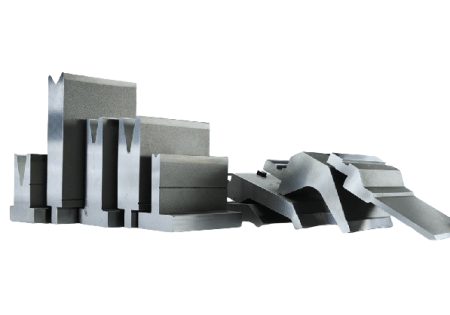

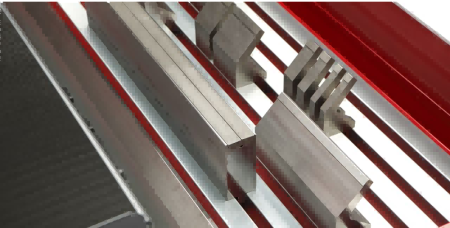

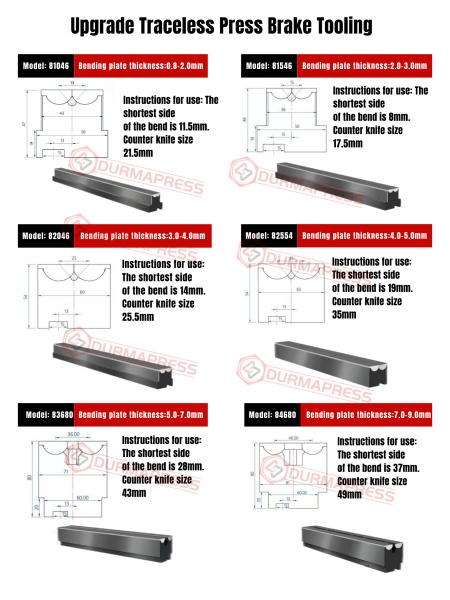

Upgrade Traceless press brake tooling

This line of upgraded bending dies offers a wide range of sizes for bending sheets of different thicknesses. From 0.8mm to 9.0mm sheet thicknesses, there is a tooling available for each. Whether you need a minimum 11.5mm bending edge or a 37mm bending edge, these toolings will meet your needs. Equipped with counterblade sizes that vary from 17.5mm to 49mm. These specifications and instructions make these dies ideal for working with a wide range of sheet thicknesses and sizes.

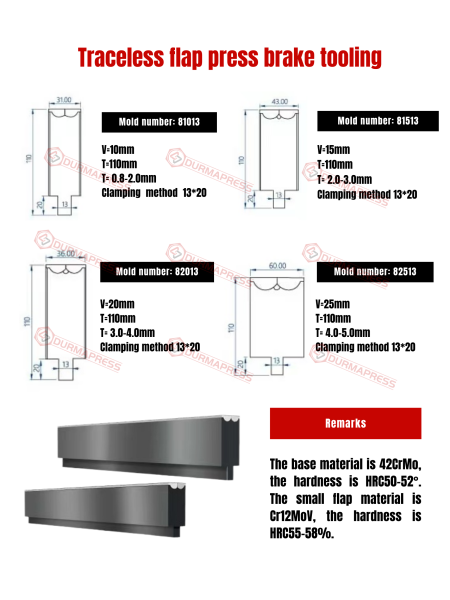

Traceless flap press brake tooling

This line of Single V Seamless Reproduction Bending Dies offers a wide range of specifications for a variety of sheet thicknesses. Whether the plate thickness is 0.8mm to 5.0mm, these dies have corresponding V-shape and bending radius of 10mm to 25mm respectively. equipped with clamping method of 13*20, which is suitable for different types of dies. In terms of material, the base material is 42CrMo with a hardness of HRC50-52°, while the winglets are made of Cr2MoV with a hardness of HRC55-58°. These characteristics make these toolings suitable for plate bending processing of various thicknesses and sizes.

Application and development of Traceless press brake toolings

Precision Instrument Manufacturing

In the field of precision instrument manufacturing, such as optical devices, medical devices, etc., the Traceless press brake toolings can ensure the perfect appearance of the products and avoid affecting their performance and precision due to indentation or abrasion.

Electronic Product Manufacturing

Electronic products such as cell phones, tablet PCs, TVs, etc. require very high quality appearance, and the application of Traceless press brake toolings can ensure the flawless appearance of the products and enhance the competitiveness of the products.

Automobile parts

In the production of automotive interior and exterior parts, the use of Traceless press brake toolings can ensure that the surface of the parts is smooth and free of marks, enhancing the overall appearance of the car quality.

Aerospace Manufacturing

The manufacture of aircraft and aerospace components requires high-precision parts, and the use of Traceless press brake toolings in these fields can ensure the appearance quality and performance of products.

Environmental Revolution

Reduce scrap rate

Traceless press brake toolings can reduce the scrap rate during product processing, because there are fewer product damages caused by tooling marks, reducing the scrap rate and conforming to the concept of environmental protection.

Resource Saving

As the application of Traceless press brake toolings can improve product quality and production efficiency, thus reducing the waste of resources, it is an effective way to save resources.

Reduce energy consumption

The production of quality products can reduce the scrap rate, reduce the number of repeated processing, thus reducing energy consumption, which is significant for environmental protection.

Industrial production

Improve production efficiency

The application of Traceless press brake toolings can reduce the frequency of tooling replacement, improve the stability and efficiency of the production line, and save production time and cost.

Ensure product quality

Traceless press brake toolings can ensure the quality of product appearance, avoid product defects caused by tooling marks, and improve the overall quality of products.

Expand Market Competitiveness

Producing high quality and flawless products can enhance the market competitiveness of the enterprise, attract more consumers and increase sales.

Future Direction

Intelligent Manufacturing

The future development of markless toolings may be combined with intelligent manufacturing technology to achieve automated adjustment and optimization of toolings, improving production efficiency and precision.

Application of new materials

With the continuous development of new materials, future Traceless press brake toolings may adopt more advanced materials to improve wear resistance and durability.

Customized Production

With the personalization and diversification of consumer demands, future no-trace toolings may be more customized, with different toolings designed for different product needs.

Green Manufacturing

The future development of no trace tooling will also pay more attention to environmental protection, the use of environmentally friendly materials, energy-saving technology, to achieve green manufacturing.

Quiénes somos

Durmapress se especializa en el diseño, la fabricación y la venta de diversos equipos de procesamiento de metales, como plegadoras, cizallas, punzonadoras, máquinas de corte por láser, etc. La empresa se fundó en 2000. Con años de experiencia y acumulación de tecnología. DurmaPress se ha convertido en una de las marcas más conocidas de la industria china de maquinaria para el procesamiento de metales.

Póngase en contacto con nosotros

Entradas recientes

Categorías

Síguenos

Nuevo vídeo semanal

Más información

Si tiene alguna información sobre nuestros productos, póngase en contacto con nosotros y le responderemos en 24 horas.

-300x169.jpg)