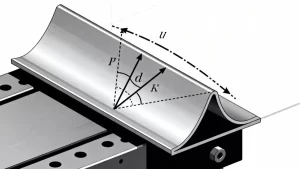

The WE67K hydraulic press brake boasts a sturdy steel welded structure, with sufficient strength and rigidity. The hydraulic transmission slider synchronizes through the torque shaft and mechanical block to achieve a stable and reliable diagonal wedge-type deflection compensation structure. With a slider stroke with quick adjustment, manual fine adjustment, and counter display, and a rear stopper for quick adjustment, this machine can precisely control bending operations.

Operated by hydraulic and electric control, the press brake allows for flexible adjustment of the slide stroke, facilitating various operation modes, including manual, semi-automatic, and automatic. This versatility streamlines die testing and adjustment. The top-traveling bending design driven by dual oil cylinders ensures smooth and safe operation and maintains balance during use.

In addition, the press brake includes a calendar function for the bottom dead center, which improves the accuracy of the workpiece. It complies with the JB/T22572-1999 national standard, which ensures precise bending angle accuracy. The slow-speed descent control function allows the operator to better control the workpiece during operation.

To address the synchronization problem of hydraulic press brakes, pay attention to both the piston-cylinder and the oil inlet and return pipelines. The unequal moving speed of the two cylinders may be caused by internal leakage of the piston-cylinder or mismatched design of the oil inlet pipeline. Solutions include optimizing the matching accuracy between the left and right piston-cylinders and hydraulic circuit design. Similarly, equalizing the oil return resistance of the return pipeline is also important for synchronization. Finally, a mechanical rack-and-pinion drive system enforces synchronization and provides high accuracy when manufacturing precision racks and gears.

Quiénes somos

Durmapress se especializa en el diseño, la fabricación y la venta de diversos equipos de procesamiento de metales, como plegadoras, cizallas, punzonadoras, máquinas de corte por láser, etc. La empresa se fundó en 2000. Con años de experiencia y acumulación de tecnología. DurmaPress se ha convertido en una de las marcas más conocidas de la industria china de maquinaria para el procesamiento de metales.

Entradas recientes

Síguenos

Más información

Si tiene alguna información sobre nuestros productos, póngase en contacto con nosotros y le responderemos en 24 horas.