características

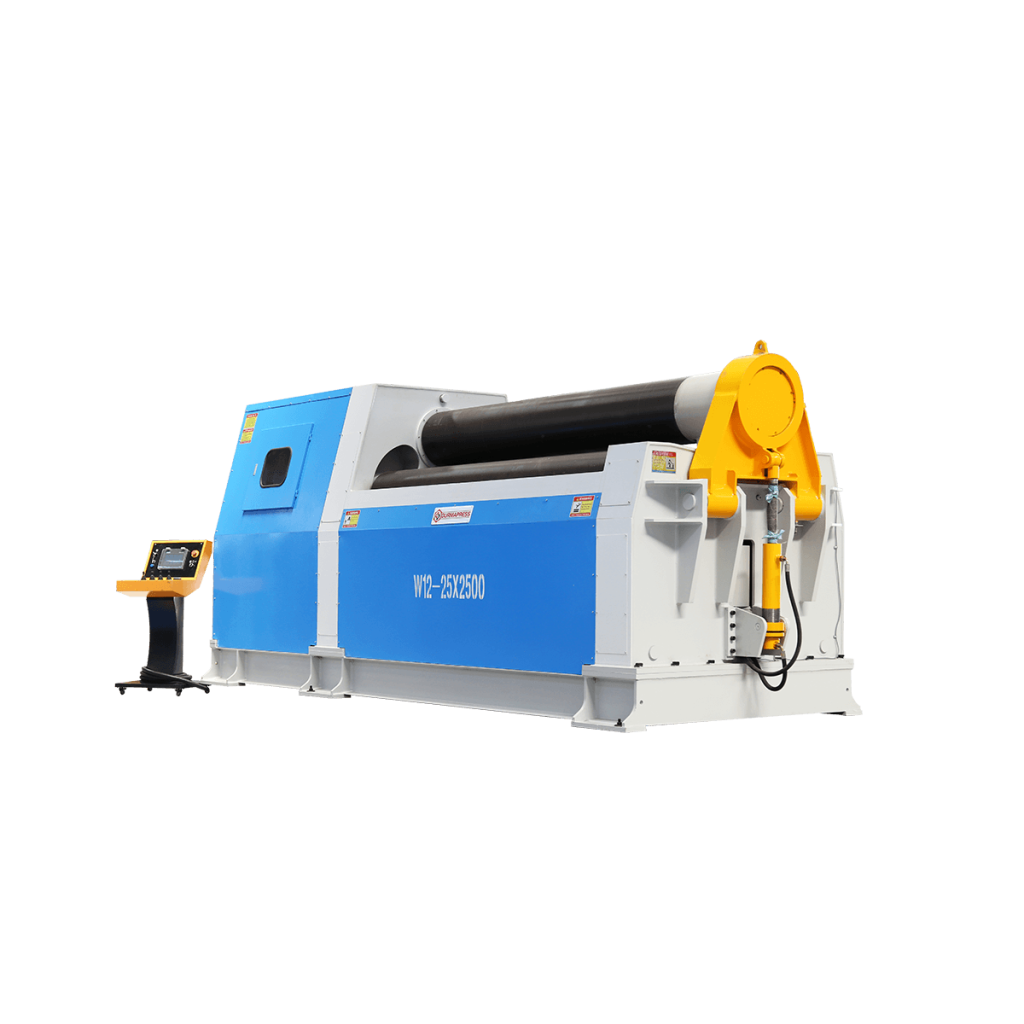

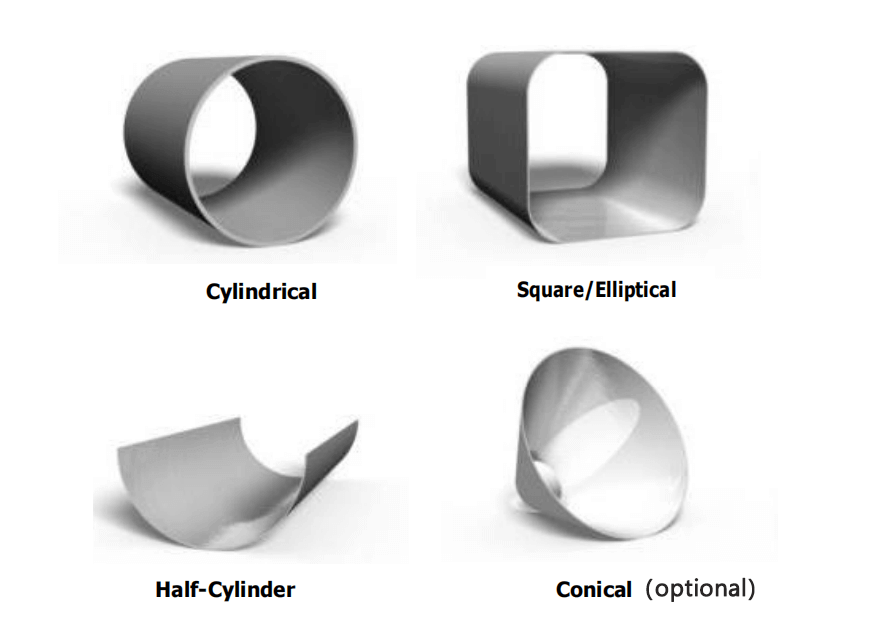

- Diseño de 4 rodillos para curvar chapas en forma cilíndrica, de arco o de cono.

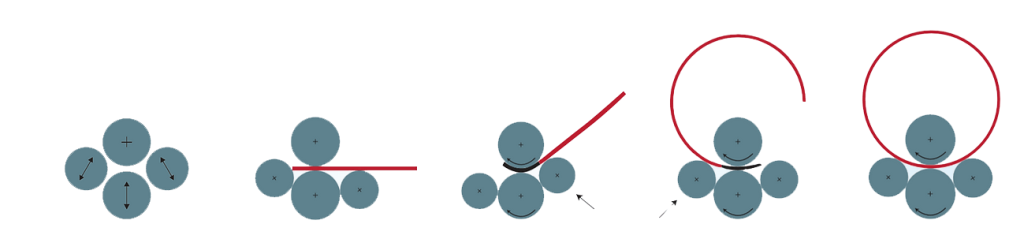

- Dispone de función de precurvado para los bordes de la chapa y puede curvar chapas en una sola pasada sin necesidad de volver a enrollar.

- El rodillo superior es el accionamiento principal, mientras que el rodillo inferior y los dos rodillos laterales se controlan mediante accionamiento hidráulico.

- El desplazamiento de los rodillos controlado por ordenador garantiza una alta precisión de sincronización de ±0,2 mm para un plegado exacto.

- Enfatiza el acabado único de los procesos de precurvado y laminado, con el rodillo superior accionado por un motor hidráulico, el rodillo inferior sujetando los materiales hidráulicamente y el funcionamiento independiente de los rodillos laterales. Incluye control PLC NC y protección contra sobrecargas.

durmapress

Accesorios de serie y opcionales

Personalice su configuración según sus necesidades

Características estándar

- Rodillos templados por inducción

- Dispositivo de curvado de conos

- Pantalla digital para siderolls

- Cuerpo de construcción sreel(St-52) totalmente soldado

- Panel de control móvil independiente

- Dos velocidades de rodadura

- Todos los rodillos están montados en rodamientos oscilantes de rodillos

- Equipo de seguridad alrededor de la máquina.

- Los rodillos centrales se accionan mediante motores hidráulicos y reductores planetarios

- Máquina certificada CE, ISO9001 -2008

Características opcionales

- Soportes centrales y laterales

- Mesa de alimentación de material con diversas características

- Refrigerado por ventilador o por agua

- Sistema automático de carga y descarga

- Cable de seguridad

- Rodillos rectificados y pulidos para trabajos especiales

- Soporte superior y lateral para diámetros grandes

durmapress

Descripción de los componentes principales

Accesorios estándar para la laminadora hidráulica CNC W12

Guías lineales

El sistema utiliza guías lineales de desgaste, lo que garantiza que las escalas de rodadura no afecten al sistema. Este sistema planetario funciona de forma segura con un mantenimiento y un tiempo de inactividad mínimos, manteniendo un cuerpo robusto incluso con diámetros de rodadura pequeños.

Diseño planetario de 4 rodillos

En estos modelos, los rodillos están templados a 50-60 HRC y abombados para compensar la flexión durante el laminado. Están pulidos con calidad DIN Ck45 y pueden ampliarse para curvar diferentes perfiles bajo pedido.

panel de control

Gracias a su movilidad, la máquina permite controlar el enrollado del material desde todos los lados. La pantalla digital de las máquinas estándar muestra las posiciones actual y máxima de los rodillos derecho e izquierdo. El panel de control puede personalizarse con botones adicionales para las funciones opcionales preferidas.

estructura corporal

Los cuerpos de los Rodillos de Placa DURMAPRESS están diseñados con análisis FEM para obtener una máxima resistencia y una estructura rígida. De esta forma, las tensiones que se producen durante el doblado se minimizan para proporcionar una vida útil de la máquina más segura y prolongada.

impulso de rodadura

Los motores hidráulicos y los reductores planetarios accionan los rodillos inferiores y superiores, garantizando una rodadura eficaz. El reductor planetario se conecta directamente a los ejes de los rodillos, transfiriendo el impulso sin pérdida de potencia. Un freno de parada hidráulico aumenta la seguridad durante el precurvado.

parte electrónica

Todos los rodillos están soportados por rodamientos de rodillos a rótula, que pueden soportar cargas pesadas y facilitar los movimientos cónicos. Estos rodamientos funcionan con gran precisión y durabilidad, incluso en condiciones difíciles. Al reducir la fricción, ahorran energía, lo que garantiza que se utilice toda la potencia para dar forma al material.

Pida presupuesto ahora

Póngase en contacto con nosotros para obtener más información sobre la laminadora hidráulica

Por qué elegirnos

de principio a fin

Durmapress siempre se adhiere al concepto de poner a los clientes en primer lugar en toda la experiencia de compra, y optimiza e innova continuamente el proceso de producción para satisfacer las necesidades de todas las empresas de fabricación grandes, medianas y pequeñas.

- Más de 20 años de experiencia

- Máquinas personalizadas

- Perfecto sistema posventa

- Disponibilidad 24/7

Más información

Cuáles son las ventajas del dispositivo opcional?

1

Dispositivo de curvado de conos

Lograr el curvado cónico con la W12 es sencillo. Los rodillos inferiores se inclinan para crear la forma cónica, un proceso fácilmente controlado y supervisado por el microprocesador electrónico (disponible en determinados modelos).

Nuestro sistema de control garantiza un retorno preciso a la posición paralela tras el curvado del cono, asegurando precisión y consistencia en tareas repetitivas.

2

Sistema automático de carga y descarga

Los sistemas automáticos de carga y descarga ofrecen varias ventajas clave. Aumentan la eficacia al acelerar el proceso y reducen el riesgo de lesiones asociadas a la manipulación manual. Además, la automatización garantiza operaciones coherentes y fiables, minimizando los errores. Esta tecnología también ahorra costes de mano de obra y mejora la productividad general al permitir un funcionamiento continuo. Por último, estos sistemas pueden diseñarse para optimizar la utilización del espacio en la zona de trabajo.

3

Soporte superior y lateral para diámetros grandes

El soporte superior y lateral para grandes diámetros en una laminadora ofrece varias ventajas. Garantiza la estabilidad y la precisión durante el proceso de laminado, especialmente cuando se manipulan materiales más grandes y pesados. Este sistema de soporte ayuda a evitar deformaciones y mantiene la forma de la pieza, lo que se traduce en productos acabados de alta calidad.

4

Refrigerado por ventilador o por agua

Los sistemas de refrigeración por ventilador o por agua de las máquinas laminadoras ofrecen varias ventajas. Ayudan a mantener temperaturas de funcionamiento óptimas, evitando el sobrecalentamiento y garantizando un rendimiento constante. Estos sistemas de refrigeración también ayudan a prolongar la vida útil de los componentes de la máquina al reducir el desgaste causado por el calor excesivo.

Principio de funcionamiento

Características de la máquina laminadora de chapa mecánica

Sistema hidráulico

Utiliza una bomba de pistones de caudal variable para ofrecer resistencia a alta presión, durabilidad y bajo nivel de ruido. El motor hidráulico especialmente diseñado ofrece un funcionamiento eficiente con un consumo de energía mínimo y una mayor velocidad.

Incorpora un sistema de control hidráulico integrado de YUKUN-Japón para mayor fiabilidad y facilidad de mantenimiento. Incluye protección contra sobrecarga por rebosamiento para un funcionamiento sin fugas y control directo del nivel de aceite. Cumple la Directiva 98/37 CE.

Electrical System & Safety

El armario eléctrico cumple la norma IP65 y cuenta con la certificación CE, lo que garantiza su seguridad y fiabilidad con una gran capacidad antiinterferencias. Equipado con vallas protectoras, enclavamientos de seguridad y un interruptor de pedal monomanual móvil para facilitar el manejo.

Las cubiertas laterales frontales incluyen interruptores de seguridad, protectores de seguridad de retroiluminación (categoría 4) y un pedal conforme a la normativa CE para mejorar la seguridad durante el funcionamiento.

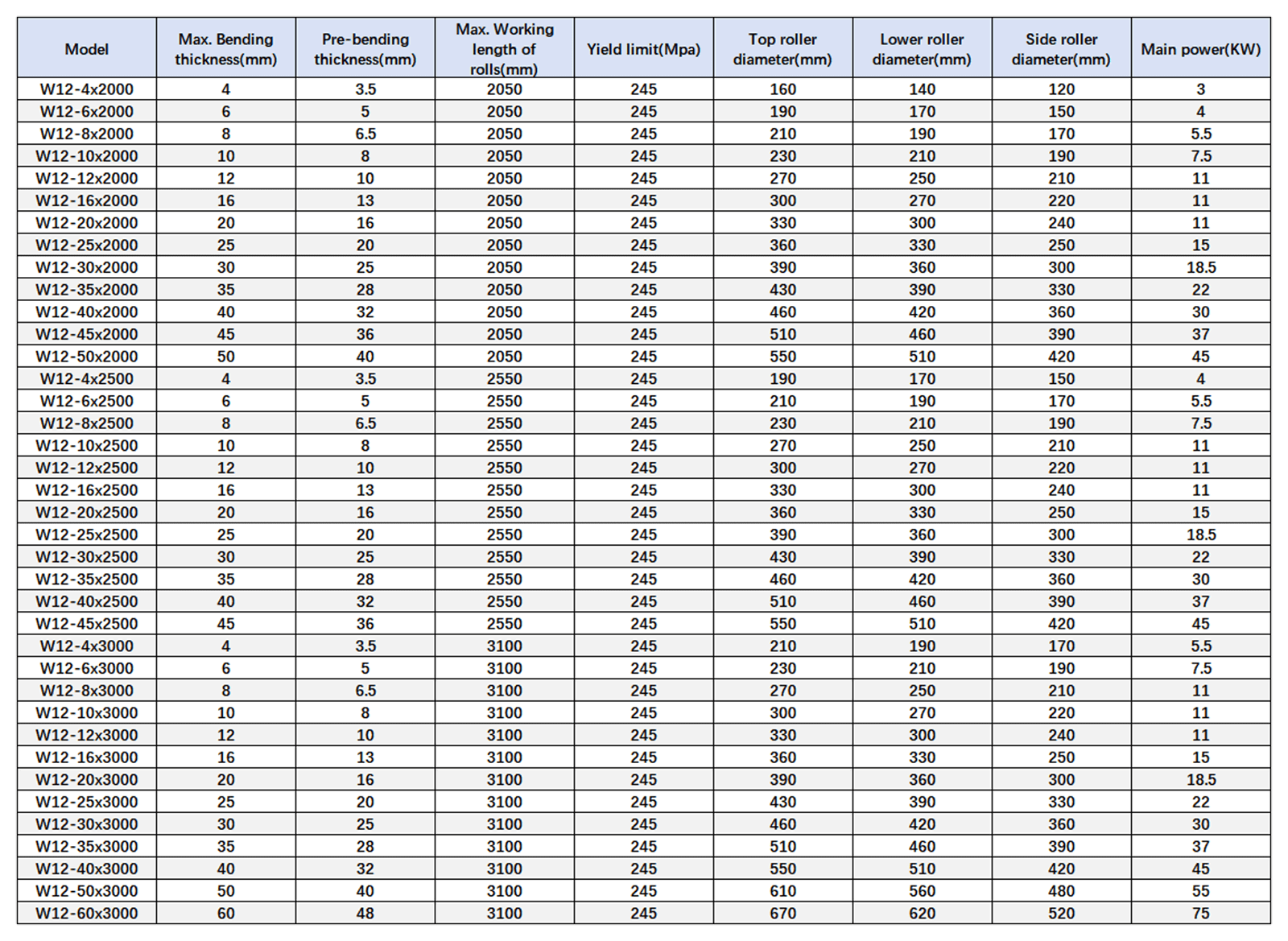

parámetros técnicos

durmapress

formas comunes de laminado

fábrica de durmapress

Ver el vídeo

Póngase en contacto con nosotros

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

7/24