características

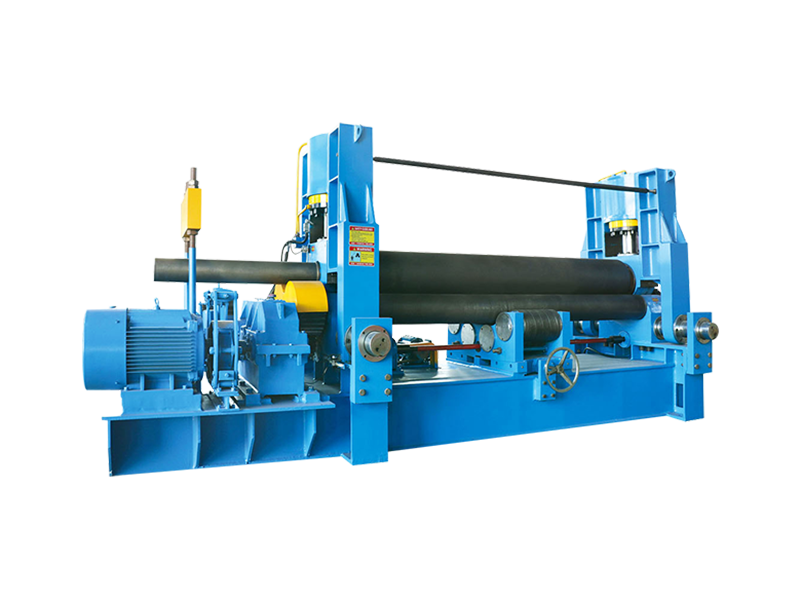

- Su diseño compacto mejora la portabilidad de máquinas medianas y grandes.

- El movimiento horizontal de los rodillos inferiores reduce el tamaño de la fosa de cimentación y la carga.

- Las placas permanecen horizontales durante el predoblado y el laminado, lo que facilita la manipulación del material.

- Su estructura sólida y especialmente diseñada aumenta su idoneidad para diversas aplicaciones.

- La pequeña distancia entre ejes del rodillo inferior es ideal para el precurvado de chapas finas con diámetros pequeños.

- Proceso de descarga simplificado en comparación con algunas máquinas de 3 y 4 rodillos.

- Ofrece una gran carrera de trabajo para mejorar los efectos de laminado y la capacidad de placas más gruesas.

- Dispone de rodillos forjados endurecidos por inducción o rodillos de acero laminado SAE1050.

- Incluye sistema de trabajo de doble velocidad y dispositivo de plegado cónico.

durmapress

Accesorios de serie y opcionales

Personalice su configuración según sus necesidades

Características estándar

- Rodillos macizos de 42CrMo

- Piezas eléctricas Siemens

- Control PLC

- Mando a distancia

- Equipo de seguridad alrededor de la máquina.

- Panel de control móvil

- Máquina certificada CE, ISO9001 -2008

Características opcionales

- Dispositivo de curvado de conos

- Cubierta de la máquina

- Soporte superior para diámetros grandes

- Sistema automático de carga y descarga

- Cable de seguridad

- Cremallera de soporte lateral para diámetros grandes

durmapress

Descripción de los componentes principales

Accesorios estándar para la laminadora hidráulica W11S

Guías lineales

El sistema utiliza guías lineales de desgaste, lo que garantiza que las escalas de rodadura no afecten al sistema. Este sistema planetario funciona de forma segura con un mantenimiento y un tiempo de inactividad mínimos, manteniendo un cuerpo robusto incluso con diámetros de rodadura pequeños.

Diseño planetario de 3 rodillos

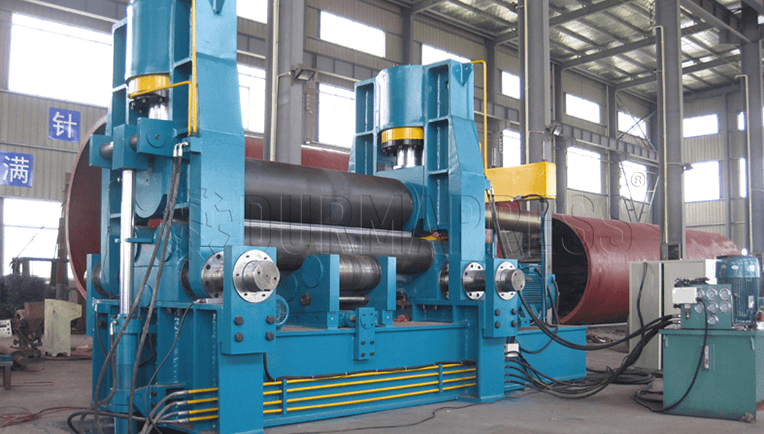

La curvadora de chapas de tres rodillos W11 es una herramienta versátil y eficaz para curvar chapas metálicas. Su diseño mecánico incluye dos rodillos motrices inferiores accionados por un motor y un reductor, mientras que el rodillo superior es accionado y controlado por un motor, un reductor, un tornillo sinfín y un mecanismo de engranajes.

motor

La laminadora hidráulica W11S funciona con un motor de alta eficiencia que ofrece un control preciso, ahorro de energía y un rendimiento fiable. Su diseño garantiza la facilidad de mantenimiento, por lo que es una opción ideal para diversas aplicaciones de laminación.

estructura corporal

Los cuerpos de los Rodillos de Placa DURMAPRESS están diseñados con análisis FEM para obtener una máxima resistencia y una estructura rígida. De esta forma, las tensiones que se producen durante el doblado se minimizan para proporcionar una vida útil de la máquina más segura y prolongada.

Pida presupuesto ahora

Póngase en contacto con nosotros para obtener más información sobre la laminadora hidráulica

Por qué elegirnos

de principio a fin

Durmapress siempre se adhiere al concepto de poner a los clientes en primer lugar en toda la experiencia de compra, y optimiza e innova continuamente el proceso de producción para satisfacer las necesidades de todas las empresas de fabricación grandes, medianas y pequeñas.

- Más de 20 años de experiencia

- Máquinas personalizadas

- Perfecto sistema posventa

- Disponibilidad 24/7

Más información

¿Qué otras características tiene la laminadora hidráulica?

1

Alta precisión

Los sistemas hidráulicos proporcionan un control preciso del proceso de laminado, garantizando ángulos y dimensiones de plegado exactos.

2

Eficacia

Los sistemas hidráulicos pueden ejercer altos niveles de fuerza, lo que permite velocidades de rodadura más rápidas y una mayor productividad.

3

Durabilidad

Los sistemas hidráulicos son conocidos por su durabilidad y fiabilidad, que garantizan un rendimiento a largo plazo con un mantenimiento mínimo.

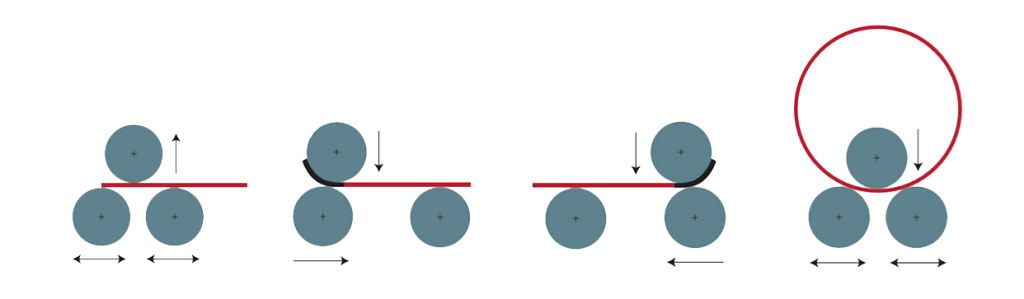

Principio de funcionamiento

Características de la máquina laminadora de chapa mecánica

Sistema hidráulico

Utiliza una bomba de pistones de caudal variable para ofrecer resistencia a alta presión, durabilidad y bajo nivel de ruido. El motor hidráulico especialmente diseñado ofrece un funcionamiento eficiente con un consumo de energía mínimo y una mayor velocidad.

Incorpora un sistema de control hidráulico integrado de YUKUN-Japón para mayor fiabilidad y facilidad de mantenimiento. Incluye protección contra sobrecarga por rebosamiento para un funcionamiento sin fugas y control directo del nivel de aceite. Cumple la Directiva 98/37 CE.

Electrical System & Safety

El armario eléctrico cumple la norma IP65 y cuenta con la certificación CE, lo que garantiza su seguridad y fiabilidad con una gran capacidad antiinterferencias. Equipado con vallas protectoras, enclavamientos de seguridad y un interruptor de pedal monomanual móvil para facilitar el manejo.

Las cubiertas laterales frontales incluyen interruptores de seguridad, protectores de seguridad de retroiluminación (categoría 4) y un pedal conforme a la normativa CE para mejorar la seguridad durante el funcionamiento.

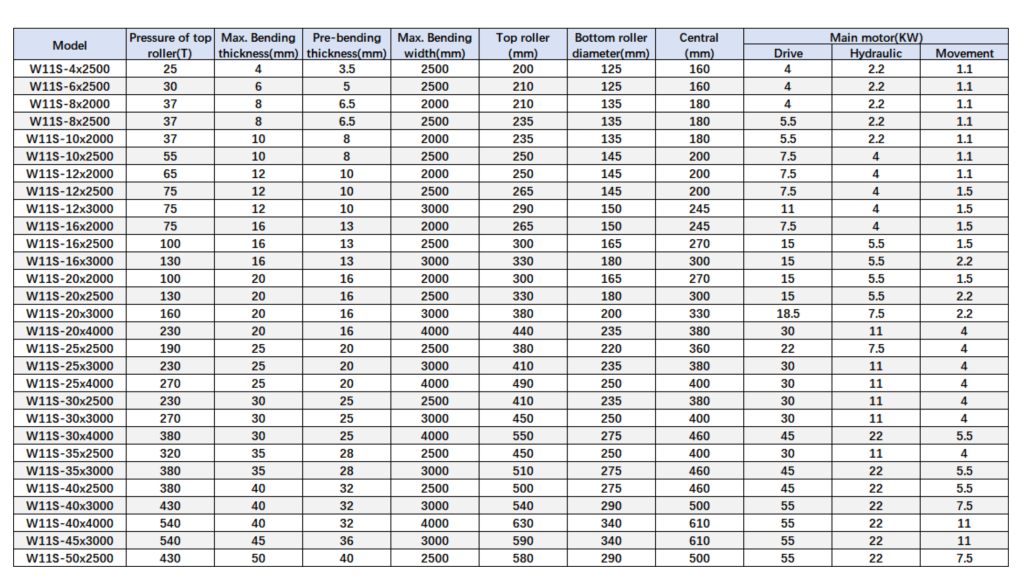

parámetros técnicos

durmapress

formas comunes de laminado

fábrica de durmapress

Ver el vídeo

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos